17

1-26

C

53

C

93

1-25

X

INS

T

ALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

1.1

6

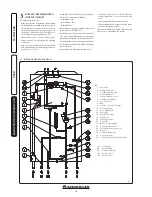

DUCTING OF FLUES OR

TECHNICAL SLOTS.

Ducting is an operation through which, via

the introduction of one or more relevant pipes,

one achieves a system for the evacuation of the

combustion products of a gas appliance, made up

from the coupling of an existing or new ducting

pipe with a chimney, flue or technical slot (also

in new buildings) (Fig. 1-26). Ducting requires

ducts declared to be suitable for the purpose by

the manufacturer, following the installation and

user instructions, provided by the manufacturer

and the requirements of the standards in force.

Immergas ducting system.

The Ø 6

0

rigid and

Ø 8

0

flexible “Green Range” ducting systems must

only be used for domestic use and with Immergas

condensing boilers.

In any case, ducting operations must respect

the provisions contained in the standard and in

current technical regulations; in particular, the

declaration of conformity must be compiled at

the end of work and on commissioning of the

ducted system. The instructions in the project

or technical report must likewise be followed, in

cases provided for by the standard and current

technical regulations. The system or components

of the system have a technical life complying with

current standards, provided that:

- it is used in average atmospheric and environ-

mental conditions, according to current regula-

tions (absence of fumes, dusts or gases that can

alter the normal thermophysical or chemical

conditions; existence of temperatures coming

within the standard range of daily variation,

etc.).

- Installation and maintenance must be per-

formed according to the indications supplied

by the manufacturer and in compliance with

the provisions in force.

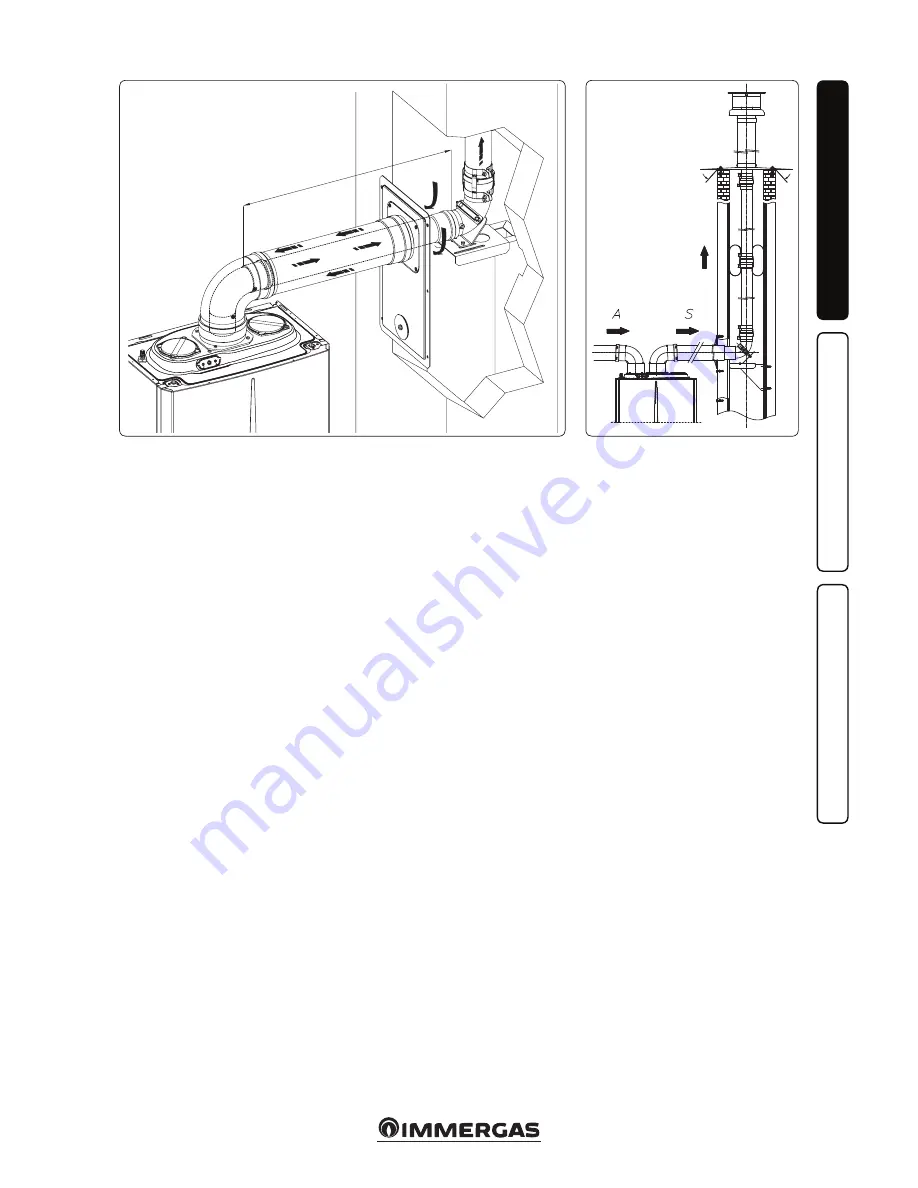

- The max. possible length of the

Ø

60 flexible

ducting vertical section is equal to 22 m. This

length is obtained considering the complete

Ø

80 exhaust terminal, 1m of

Ø

80 pipe in

exhaust, two 90°

Ø

80 bends at boiler outlet.

- The max. possible length of the

Ø

80 flexible

ducting vertical section is equal to 30 m. This

length is obtained considering the complete

exhaust terminal, 1m of

Ø

80 pipe in exhaust,

two 90°

Ø

80 bends at boiler outlet for connect-

ing to the ducting system and two direction

changes of the flexible hose inside the chimney/

technical slot.

- The maximum possible length of the

Ø

80 rigid

ducting vertical section is equal to 30 m. This

length is obtained considering the complete

Ø

80 exhaust terminal, 1m of

Ø

80 pipe in ex-

haust, two 90°

Ø

80 bends on the boiler outlet.

1.1

7

CONFIGURATION TYPE B, OPEN

CHAMBER AND FAN ASSISTED FOR

INDOORS.

The appliance can be installed inside buildings

in

23

or B

53

mode; in this case, all technical rules

and national and local regulations in force, must

be complied with.

- Type B open chamber boilers must not be

installed in places where commercial, artisan

or industrial activities take place, which use

products that may develop volatile vapours

or substances (e.g. acid vapours, glues, paints,

solvents, combustibles, etc.), as well as dusts

(e.g. dust deriving from the working of wood,

coal fines, cement, etc.), which may be harm-

ful for the components of the appliance and

jeopardise operation.

- In B

23

and B

53

configuration, the boilers must

not be installed in bedrooms, bathrooms or in

studio flats.

- The installation of appliances in B

23

and B

53

con-

figurations are only recommended outdoors (in

a partially-protected place) or in places that

are not lived in and which are permanently

ventilated.

The suitable kit referred to in paragraph 1.11

must be used for installation.

1.18 FLUE GAS EXHAUST TO FLUE/

CHIMNEY.

Flue exhaust does not necessarily have to be

connected to a branched type traditional flue.

The flue exhaust, for boiler clots installed in C

configuration, can be connected to a special LAS

type multiple flue. For B configurations, exhaust

is only allowed into individual chimney or di-

rectly into the external atmosphere via a suitable

terminal. The multiple flues and the combined

flues must also only be connected to type C ap-

pliances of the same type (condensing), having

nominal heat inputs that do not differ by more

than 30% less with respect to the maximum that

can be attached and powered by the same fuel.

The thermo-fluid dynamic features (flue flow

rate, % of carbon dioxide, % humidity etc....) of

the appliances attached to the same multiple flues

or combined flues, must not differ by more than

10% with respect to the average boiler attached.

Multiple and combined flues must be specially

designed according to the calculation method

and requirements of the technical standards

in force, by a professionally qualified company.

Chimney or flue sections for connection of the

flue exhaust pipe must comply with requisites of

technical standards in force.

1.19 FLUES, CHIMNEYS, CHIMNEY POTS

AND TERMINALS.

The flues, chimneys and chimney pots for the

evacuation of combustion products must be in

compliance with applicable standards. Chimneys

and roof-installed exhaust terminals must com-

ply with the outlet height and with the distance

from technical volumes set forth by the technical

standards in force.

Positioning the wall

fl

ue exhaust terminals.

The

wall flue exhaust terminals must:

- be installed on external perimeter walls of the

building;

- be positioned according to the minimum dis-

tances specified in current technical standards.

Combustion products exhaust of natural

draught or fan assisted appliances in open-top

closed environments.

In spaces closed on all

sides with open tops (ventilation pits, court-

yards etc.), direct combustion product exhaust

is allowed for natural draught or fan assisted gas

appliances with a heat input range from 4 to 35

kW, provided the conditions as per the current

technical standards are respected.

Summary of Contents for VICTRIX MAIOR 28 - 35 TT 1 ERP

Page 1: ...VICTRIX MAIOR 35 X TT 1 ERP IE Instruction and recommendation booklet 1 038660ENG...

Page 2: ......

Page 46: ...46...

Page 47: ...47...