18

1-27

INS

T

ALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

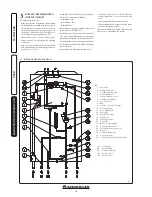

1.20 WATER TREATMENT SYSTEM

FILLING.

As already mentioned in the previous para-

graphs, a chemical treatment of the thermal

system water is required, in compliance with the

local standards in force.

The parameters that influence the duration and

proper operation of the heat exchanger are the

water's PH, hardness, conductivity, and oxygen,

together with the system's processing residues

(any welding residues), any oil present and cor-

rosion products that can, in turn, cause damage

to the heat exchanger.

In order to prevent this from happening, you are

recommended to:

- Before installation on new systems as well as

old ones, clean the system with clean water to

eliminate solid residues contained therein.

- Clean the system with a chemical treatment:

- Clean the new system with a suitable cleaning

device (for example Sentinel X300, Fernox

Cleaner F3 or Jenaqua 300) combined with

thorough washing.

- Clean the old system with a suitable cleaning

device (for example Sentinel X400 or X800,

Fernox Cleaner F3 or Jenaqua 400) combined

with thorough washing.

- Check the maximum hardness and quantity

of filling water referring to the graphics (Fig.

1-27). If the contents and hardness of the water

are below the indicated curve, no specific treat-

ment is required; otherwise, to limit the content

of calcium carbonate, you must provide for

water-filling treatment.

- For filling, you are not allowed to use water

softened with the use of ionic-exchange resins

or distilled water.

- Should you be required to provide for water

treatment, this should be carried out by

completely desalinating the filling water. As

opposed to the complete softening process,

desalinating the water completely not only

removes hardening agents (Ca, Mg), but also

eliminates all other minerals to reduce water-

filling conductivity up to 10 microsiemens/

cm. Given its low conductivity, desalinated

water does not only prevent the formation of

lime scale, but also serves as protection against

corrosion.

- Insert a suitable inhibitor / passivator (for

example Sentinel X100, Fernot Protector F1,

or Jenaqua 100); if required, also insert appro-

priate antifreeze (such as for example Sentinel

X500, Fernox Alphi 11 or Jenaqua 500).

- Check electrical conduction of the water, which

should be higher than 2000

µ

s/cm in the case

of treated water and lower than 600

µ

s/cm in

the case of non-treated water.

- To prevent corrosion, the water system's PH

should be between 6.5 and 8.5.

- Check the maximum content of chlorides,

which should be less than 250 mg/l.

N.B.:

for quantities and methods of use of water-

treatment products, refer to the instructions

provided by their manufacturer.

1.21 SYSTEM FILLING.

Once the boiler is connected, proceed with

system filling via the filling cock (Fig. 1-29 and

1-3). Filling is performed at low speed to ensure

release of air bubbles in the water via the boiler

and heating system vents.

The boiler has a built-in automatic venting valve

on the circulator.

Check if the cap is loose.

Open the

radiator vent valves.

Close radiator vent valves when only water

escapes from them.

Close the filling cock when the boiler pressure

gauge indicates approx. 1.2 bar.

N.B.:

during these operations, enable the au-

tomatic vent functions on the boiler (active on

first ignition).

1.22 CONDENSATE TRAP FILLING.

On first lighting of the boiler, flue gas may come

out the condensate drain; after a few minutes’

operation check that this no longer occurs. This

means that the drain trap is filled with conden-

sate to the correct level preventing the passage

of flue gas.

1.23 GAS SYSTEM START

-

UP.

To start up the system, refer to the technical

standard in force: This divides the systems and

therefore the start-up operations into three

categories: new systems, modified systems, re-

activated systems.

In particular, for new gas systems:

- open windows and doors;

- avoid presence of sparks or open flames;

- bleed all air from the pipelines;

- check that the internal system is properly sealed

according to the specifications set forth by

technical regulations in force.

1.24 BOILER START UP

(

IGNITION

)

.

In order to issue the Declaration of Conformity

required by the laws in force, the following re-

quirements must be fulfilled to commission the

boiler (the operations listed below must only be

performed by a qualified firm and without any

unauthorised persons):

- check that the internal system is properly sealed

according to the specifications set forth by

technical regulations in force;

- ensure that the type of gas used corresponds to

the boiler settings (the type of gas appears on

the display on first electrical supply voltage, or

by checking the relative parameter “G”);

- check connection to a 230V-50Hz power

mains, correct L-N polarity and earthing con-

nection;

- check that there are external factors that may

cause the formation of fuel pockets;

- switch the boiler on and check correct ignition;

- make sure that the gas flow rate and relevant

pressure values comply with those given in the

manual (Par. 3.22);

- ensure that the safety device intervenes in the

event of gas supply failure and check the relative

intervention time;

- check the intervention of the main switch

located upstream from the boiler and in the

boiler;

- check that the intake/exhaust concentric ter-

minal (if fitted) is not blocked.

- Carry out the flue test and set the relative

parameter "F0".

The boiler must not be started up even if only

one of the checks should be negative.

N.B.:

only upon completing commissioning by

an installer, may an authorised firm carry out an

initial inspection of the boiler, which is required to

activate the Immergas warranty. The test certificate

and warranty is issued to the user.

N.B.:

the graph refers to the

entire life cycle of the system.

Therefore, also consider sched-

uled and unscheduled mainte-

nance, which involves emptying

and filling the said system.

Water hardness °F

Sys

tem w

at

er l

it

re

s

Summary of Contents for VICTRIX MAIOR 28 - 35 TT 1 ERP

Page 1: ...VICTRIX MAIOR 35 X TT 1 ERP IE Instruction and recommendation booklet 1 038660ENG...

Page 2: ......

Page 46: ...46...

Page 47: ...47...