26

3-1

INS

T

ALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

3

BOILER COMMISSIONING

(

INITIAL CHECK

)

To commission the boiler:

- make sure that the declaration of conformity

for installation is supplied with the appliance;

- ensure that the type of gas used corresponds to

the boiler settings (the type of gas appears on

the display on first electrical power supply, or

by checking the relative parameter “G”);

- check connection to a 230V-50Hz power

mains, correct L-N polarity and the earthing

connection;

- make sure the central heating system is filled

with water and that the pressure gauge indicates

a pressure of 1-1.2 bar.

- switch the boiler on and check correct ignition;

- check the CO

2

flow rate in the flue:

- maximum (100%)

- intermediate (50%)

- minimum (0%)

the values must comply with what is indicated

in the relative table (Fig. 3.23);

- check activation of the safety device in the event

of no gas, as well as the relative activation time;

- check the intervention of the main switch lo-

cated upstream of the boiler and in the boiler;

- check that the intake and/or exhaust terminals

are not blocked;

- ensure activation of all adjustment devices;

- check the production of DHW (when the

boiler is connected to an

external storage tank

unit)

;

- check sealing efficiency of water circuits;

- check ventilation and/or aeration of the instal-

lation room where provided.

If even only a single safety check offers a negative

result, do not commission the system.

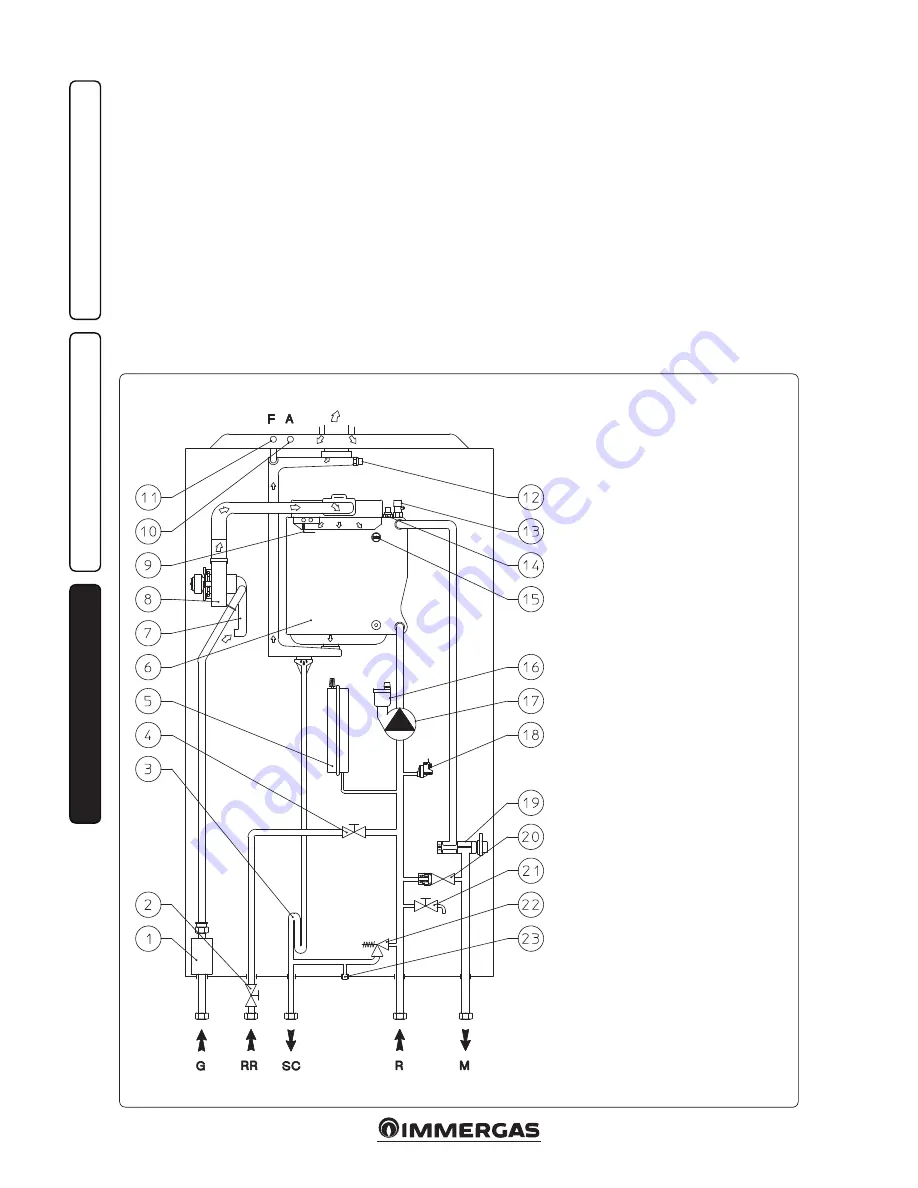

3.1 BOILER HYDRAULIC DIAGRAM.

Key:

1 - Gas valve

2 - Filling cut-off valve

3 - Condensate drain trap

4 - System filling valve

5 - System expansion vessel

6 - Condensation module

7 - Air / gas mixer

8 - Fan

9

- Ignition / detection electrode

1

0

- Air sample point

11 - Flue sample point

12 - Flue probe

13 - Manual vent valve

14 - Flow probe

15 - Safety flow probe

16 - Vent valve

17 - Boiler circulator pump

18 - System pressure switch

1

9

- Three-way valve (motorised)

2

0

- By-pass

21 - System draining valve

22 - 3 bar safety valve

23 - 3 bar safety valve drain fitting signal

G - Gas supply

RR - System filling

SC - Condensate drain

R - System return

M - System flow

Summary of Contents for VICTRIX MAIOR 28 - 35 TT 1 ERP

Page 1: ...VICTRIX MAIOR 35 X TT 1 ERP IE Instruction and recommendation booklet 1 038660ENG...

Page 2: ......

Page 46: ...46...

Page 47: ...47...