28

3-3

3-4

1

4

3

2

INS

T

ALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

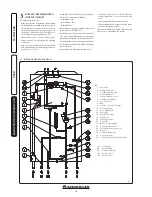

3.3 REMOVABLE MEMORY

The P.C.B. is equipped with a removable memory

(2 Fig. 3-4), which records all operation param-

eters and system customisations.

Should the P.C.B. be replaced, you can use the

memory of the replaced board again, so it is not

necessary to reconfigure the appliance.

Attention:

replacing the memory must be carried

out after disconnecting all electrical connection

of the P.C.B.

3.4 TROUBLESHOOTING.

N.B.:

maintenance operations must be carried

out by an authorised company (e.g. Authorised

After-Sales Technical Assistance Service).

- Smell of gas. Caused by leakage from gas circuit

pipelines. Check sealing efficiency of gas intake

circuit.

- Repeated ignition blocks. No gas, check the

presence of pressure in the network and that

the gas adduction cock is open.

- Irregular combustion or noisiness. It may be

caused by: a dirty burner, incorrect combustion

parameters, intake-exhaust terminal not cor-

rectly installed. Check the above components.

- Non-optimal ignition of first ignition of the

burner: even if the burner is perfectly calibrat-

ed, first ignition of the burner (after calibration)

can be sub-optimal; the system automatically

regulates ignition until it finds optimal ignition

of the said burner.

- Frequent interventions of the overheating

safety thermostat. It can depend on the lack

of water in the boiler, little water circulation

in the system or blocked pump. Check on the

manometer that the system pressure is within

established limits. Check that the radiator

valves are not closed and also the functionality

of the pump.

- Drain trap clogged. This may be caused by

dirt or combustion products deposited inside.

Check that there are no residues of material

blocking the flow of condensate.

- Heat exchanger clogged. This may be caused by

the drain trap being blocked. Check that there

are no residues of material blocking the flow of

condensate.

- Noise due to air in the system. Check open-

ing of the special air vent valve cap (Part. 18

Fig. 1-29). Make sure the system pressure and

expansion vessel pre-charge values are within

the set limits; The factory-set pressure values of

the expansion vessel must be 1.0 bar, the value

of system pressure must be between 1 and 1.2

bar.

- Noise due to air inside the condensation

module. Use the manual air vent valve (Part.

7 Fig. 1-29) to eliminate any air present in the

condensation module. When the operation has

been performed, close the manual vent valve.

- Poor production of DHW

(when the boiler is

connected to an external storage tank unit);

. If a

drop in performance is detected during supply

of D.H.W., it is possible that the condensation

module is clogged. In this case, contact Im-

mergas After-Sales Assistance Service that has

procedures to clean the module or D.H.W. heat

exchanger.

3.5 CONVERTING THE BOILER TO

OTHER TYPES OF GAS.

If the boiler has to be converted to a different type

of gas to that specified on the data nameplate,

proceed as follows:

The gas conversion operation must be carried

out by an authorised company (e.g. Authorised

Technical After-Sales Service).

To convert to another type of gas the following

operations are required:

- Select, via programming menu “G”, the type of

gas by selecting “nG” for methane gas and “LG”

for LPG gas (See par. 3.12).

- Carry out complete calibration (see par. 3.8);

during the procedure check and, if necessary,

correct the air - gas ratio.

- Upon completing the conversion, apply the

sticker regarding the modified gas content onto

the data nameplate in the connection box.

These adjustments must be made with reference

to the type of gas used, following that given in

the table (Par. 3.22).

3.

6

CHECKS FOLLOWING

CONVERSION TO ANOTHER TYPE

OF GAS.

After having made sure that the conversion is

complete and that the calibration has been suc-

cessful, you must make sure that:

- there is no flame in the combustion chamber

- the burner flame is not too high or low and that

it is stable (does not detach from burner)

- the pressure testers used for calibration are

perfectly closed and there are no leaks from

the gas circuit.

N.B.:

all boiler adjustment operations must be

carried out by a qualified company (e.g. Author-

ised After-Sales Assistance).

P.C.B.

Key:

1 - Fuse 3.15 AF

2 - Removable memory

(A1

9

)

GAS valve SGV 100 B

&

P

Key:

1 - Gas valve outlet pressure point

2 - Coil

3 - Wiring connector

4 - Gas valve inlet pressure point

Summary of Contents for VICTRIX MAIOR 28 - 35 TT 1 ERP

Page 1: ...VICTRIX MAIOR 35 X TT 1 ERP IE Instruction and recommendation booklet 1 038660ENG...

Page 2: ......

Page 46: ...46...

Page 47: ...47...