29

INS

T

ALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

3.

7

CALIBRATION TYPE INVOLVING

THE REPLACEMENT OF A

COMPONENT.

When performing extraordinary maintenance

on the boiler, involving the replacement of a

component, such as the P.C.B. (if the removable

memory is not put into the replacement board)

or components in the air, gas and flame control

circuits, the boiler will need to be calibrated.

Select the type of calibration to be carried out

according to the table below.

Replaced

component

Type of calibration

required

Gas valve

Quick calibration

Fan

Quick calibration

Burner

Complete calibra-

tion with air-gas ratio

check

Ignition/detection

electrodes

Complete calibra-

tion with air-gas ratio

check

P.C.B.

(New virgin P.C.B.

without removable

memory recovery)

Restore the param-

eters as described in

the paragraph "P.C.B.

programming"

Complete calibra-

tion with air-gas ratio

check

P.C.B.

(Recovery of the

removable memory

with the boiler

parameters set from

the replaced board)

No calibration re-

quired.

3.8 COMPLETE CALIBRATION

FUNCTION.

N.B.:

before carrying out complete calibration,

ensure that all the requirements indicated in

paragraphs 1.22 and 1.23 have been fulfilled.

IMPORTANT NOTE:

to access this function

it is crucial that there are no active requests for

central heating or DHW production.

In the event of anomaly “62” or “72” (see parag.

2.5) the boiler cancels any requests by itself.

N.B.:

during the various calibration stages, the

air - gas ratio can be checked and possibly cor-

rected as described in par. 3.9.

The energy produced is dissipated via the heat-

ing circuit; alternatively, the energy can be

released from the DHW circuit by opening any

hot water tap.

Caution:

in this case the only active temperature

control is the flow probe that limits the maximum

temperature exiting the boiler at 90°C, therefore

be careful not to get burned.

- The calibration procedure involves various

stages:

- nominal heat output calibration;

- intermediate heat output ignition calibration;

- minimum heat output calibration;

- calibration self-check.

Each calibration procedure, if carried out without

altering the parameters, lasts 5 minutes at the

most, after which it switches automatically to

the next parameter until the calibration process

is complete.

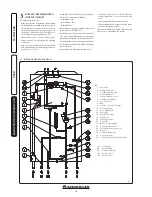

In order to access the complete calibration

stage, you must switch the boiler on, set the

DHW selector in the “6 o' clock” position and

the heating selector in the “9 o' clock” position,

(Fig. 3-5) and press the “Reset” button for about

8 seconds until the “chimney sweep” function

is activated; then press the “summer / winter”

button within 3 seconds.

•

Nominal heat output:

with the function active,

the boiler carries out the procedures required

to calibrate the appliance at the nominal heat

output.

At this stage the display features flashing

icons: “summer”, “winter”, “stand-by” and the

operating temperature alternated with the

current operating heat output (99%); once the

parameters are detected and stabilised, the

frame of the flame presence symbol (ref. 10 fig.

2-1) will start flashing (this procedure may last

a few minutes), meaning that the nominal heat

output parameters have been set.

The air - gas ratio can only be corrected after

the flame presence frame has flashed (see parag.

3.9) or switch to the next heat output parameter

by pressing the “info” button.

3-5

3-6

•

Intermediate heat output ignition:

once the

nominal heat output calibration is confirmed,

the boiler is calibrated with the intermediate

heat output (or ignition heat output).

At this stage the display features flashing

icons: “summer”, “winter”, “stand-by” and the

operating temperature alternated with the cur-

rent operating heat output (typically 41% but

variable according to the boiler model); once

the parameters are detected and stabilised, the

frame of the flame presence symbol will start

flashing, meaning that the intermediate heat

output parameters have been set.

The air - gas ratio can only be corrected after

the flame presence frame has flashed (see parag.

3.9) or switch to the next heat output parameter

by pressing the “info” button.

•

Minimum heat output:

after having calibrated

the boiler with the intermediate heat output, it

is calibrated with the minimum heat output.

At this stage the display features flashing

icons: “summer”, “winter”, “stand-by” and the

operating temperature alternated with the

current operating heat output (0%); once the

parameters are detected and stabilised, the

frame of the flame presence symbol will start

flashing, meaning that the minimum heat

output parameters have been set.

The air - gas ratio can only be corrected after

the flame presence frame has flashed (see parag.

3.9) or exit the calibration mode by pressing the

“summer / winter” button.

•

Calibration self-check:

once calibration opera-

tions are complete, the boiler runs a self-check

for about one minute. During this check, the

boiler can run at different powers and it is not

possible to apply modifications to the operat-

ing parameters or to delete the operation in

progress. Moreover, it is important not to cut

the boiler's power.

3-7

3-8

Summary of Contents for VICTRIX MAIOR 28 - 35 TT 1 ERP

Page 1: ...VICTRIX MAIOR 35 X TT 1 ERP IE Instruction and recommendation booklet 1 038660ENG...

Page 2: ......

Page 46: ...46...

Page 47: ...47...