30

INS

T

ALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

3.9 ADJUSTING THE AIR GAS RATIO

During complete calibration (par. 3.8), you can

modify the values of the air - gas ratio.

To have an exact value of CO

2

in the flue, the

technician must insert the sampling probe to the

bottom of the sample point, then check that the

CO

2

value is that specified in the table (Par. 3.23),

(with maximum tolerance equal to

±

0.2 %);

otherwise, modify the value as described below:

- during calibration, when the frame of the

flame presence starts flashing (indicating the

correct acquisition of the parameters) it is

possible to alter the CO

2

value by pressing the

“Reset” button. At this stage the display features

flashing icons: “summer”, “winter”, “stand-by”,

“flame presence”, “external connected devices

presence” and the operating temperature is

displayed, alternated with the combustion

setting.

- To increase the combustion setting, press the

“Stand-by” button; to decrease it, press the

“Info” button. As the combustion setting in-

creases, the CO

2

value decreases and vice-versa.

- Once the parameter has been altered wait for

the value to be saved (displayed via the frame

of the flame presence symbol flashing).

- To confirm the set value press the “Reset” but-

ton.

3.10 FAST CALIBRATION.

This function allows you to calibrate the boiler

automatically without requiring or giving the

possibility to alter the parameters. Typically

“fast calibration” is used after having set the type

of flue in menu “F”, which once altered causes

anomaly “72”.

N.B.:

before performing quick calibration, ensure

that all the requirements indicated in paragraphs

1.20 and 1.21 have been fulfilled.

IMPORTANT NOTE:

to access this function

it is crucial that there are no active requests for

central heating or DHW production.

In the event of anomaly “62” or “72” (see parag.

2.5) the boiler cancels any requests by itself.

The energy produced is dissipated via the heat-

ing circuit; alternatively, the energy can be

released from the DHW circuit by opening any

hot water tap.

Caution:

in this case the only active temperature

control is the flow probe that limits the maximum

temperature exiting the boiler at 90°C, therefore

be careful not to get burned.

3-

9

In order to access the fast calibration stage, set

the DHW selector in the “6 o' clock” position and

the heating selector in the “9 o' clock” position,

(Fig. 3-10) and press the “Reset” button for about

8 seconds until the “chimney sweep” function is

activated; then press the “info” button within

3 seconds.

Once the function is active, the boiler sequential-

ly carries out the procedures required to calibrate

the appliance with the nominal, intermediate and

minimum heat output values.

At this stage the display features flashing icons:

“summer”, “winter”, “stand-by”, “external probe”,

“solar probe” and the operating temperature is

displayed, alternated with the current operating

heat output.

The calibration stages (nominal, intermediate

and minimum) progress automatically and you

must wait until calibration is complete.

3.11 FLUE TEST.

To define the value to set in the ”flue length”

“F0” parameter, detect the parameters during

the “flue test”.

Attention:

Before performing the test, ensure

that the condensate drain trap has been filled

correctly and check that there are no obstructions

in the air intake circuit and flue exhaust.

Once the test has been carried out properly, note

the detected value in the relevant table, in order

to have it available for future checks.

To activate this mode, the boiler must be in

“stand-by” mode, which is visible when the

(

) symbol appears.

IMPORTANT NOTE:

if the boiler is connected

to the CAR

V2

the “stand-by” function can only be

activated via the remote control panel.

3-1

0

3-11

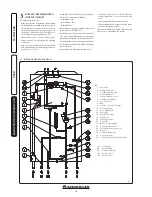

To activate the function, press the “Reset” (2) and

“on/off ” (6) buttons simultaneously until func-

tion activation, which is displayed by indicating

the fan operation speed (in hundreds of revs) and

ignition of the flashing “D.H.W.” (8) and central

heating symbols.

The appliance remains in this mode for a maxi-

mum period of 15 minutes, keeping the fan speed

constant.

This function ends once 15 minutes have elapsed,

or by disconnecting supply voltage to the boiler,

or by pressing the “on/off ” (6) button for ap-

proximately 8 seconds.

Check the ΔP between the two pressure test

outlets (Fig. 1-29 Ref. 11) and set parameter F0

according to the values shown in the tables below:

Victrix Maior 35 X TT 1 ErP

Parameter F0

Pressure

0

<

180 Pa

1

181

÷

230 Pa

2

231

÷

260 Pa

Detected Value

(Upon first check)

N.B.:

examinations are carried out by sealing the

holes provided to analyse the flues, making them

pneumatically sealed.

Attention:

in the event of finding greater values

compared to those indicated in the previous

table, do not alter parameter “F0”.

Attention:

should there be a boiler malfunction,

you can carry out a flue test to check that there

are no obstructions in the flue system. Different

values to those indicated in the previous tables

indicate a flue system malfunction, especially

a flue system with excessive load losses or ob-

structed system.

3-12

Summary of Contents for VICTRIX MAIOR 28 - 35 TT 1 ERP

Page 1: ...VICTRIX MAIOR 35 X TT 1 ERP IE Instruction and recommendation booklet 1 038660ENG...

Page 2: ......

Page 46: ...46...

Page 47: ...47...