35

3-14

INS

T

ALLER

US

ER

MAINTEN

AN

CE TECHNI

CI

AN

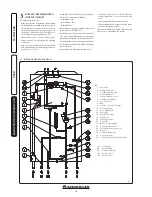

Victrix Maior 35 X TT 1 ErP

CO

2

at nominal

output

(99 %)

CO

2

at intermediate

output

(41 %)

CO

2

at minimum

output

(0 %)

G 20

9.50

±

0.80

9.00

±

0.80

9.00

±

0.80

G 31

10.50

±

1.00

10.00

±

1.00

10.00

±

1.00

N.B.:

measurements and calibration must be carried out by using regularly-

calibrated instruments.

3.20 YEARLY APPLIANCE CHECK AND

MAINTENANCE.

The following checks and maintenance should

be performed at least once a year.

- Check that the system's water PH is between

6.5 and 8.5.

- Visually check for water leaks or oxidation

from/on fittings and traces of condensate

residues inside the sealed chamber.

- Check contents of the condensate drain trap.

- Check that there are no residues of material

clogging the condensate passage; also check

that the entire condensate drainage circuit is

clear and efficient.

- Visually check that the water safety drain valve

is not clogged.

- Check that, after discharging system pressure

and bringing it to zero (read on boiler pressure

gauge), the expansion vessel pressure is at 1.0

bar.

- Check that the system static pressure (with

system cold and after refilling the system by

means of the filling valve) is between 1 and 1.2

bar.

- Visually check that the safety and control

devices have not been tampered with and/or

short-circuited.

- Check the condition and integrity of the electri-

cal system and in particular:

- supply voltage cables must be inside the

fairleads;

- there must be no traces of blackening or

burning.

- Check ignition and operation.

- Check correct calibration of the burner in

domestic hot water and central heating phases.

- Check the operation of the appliance control

and adjustment devices and in particular:

- system regulation probes intervention;

- the intervention of the DHW adjustment

thermostat

(when the boiler is connected to

an external storage tank unit)

.

- Check sealing efficiency of the gas circuit and

the internal system.

- Verify the intervention of the ionisation flame

control no gas device:

- Check the CO

2

by using the chimney sweep

function at the three reference heat outputs

and using the parameters in Fig. 3-14. Should

values out of the indicated tolerance range be

detected, check the integrity of the ignition /

detection electrode and, if required, change it,

also changing the relative gasket. At this point,

activate the “complete calibration” function.

- Carry out the flue test. Values below 40%

compared to the pressures detected upon first

check, suggest a clogged burner or module (flue

side).

Attention:

the burner does not need to be

opened for normal maintenance of the appli-

ance. However, should it be removed, you must

change the gasket.

IMPORTANT NOTE:

in addition to yearly

maintenance, you must also check the thermal

system and energy efficiency, with the frequency

and procedures that comply with the technical

regulations in force.

Summary of Contents for VICTRIX MAIOR 28 - 35 TT 1 ERP

Page 1: ...VICTRIX MAIOR 35 X TT 1 ERP IE Instruction and recommendation booklet 1 038660ENG...

Page 2: ......

Page 46: ...46...

Page 47: ...47...