24

INS

TALLER

U

SER

M

AINTEN

AN

CE

TECHNI

CI

AN

TECHNI

CAL

D

AT

A

1.12 IMMERGAS FLUE SYSTEMS

Immergas supplies various solutions separately from the appliances regarding the installation of air intake terminals and flue extraction,

which are fundamental for appliance operation.

The appliance must be installed with an original Immergas “Green Range” inspectionable air intake system and flue gas extrac-

tion system made of plastic, with the exception of configuration C

6

, as required by the regulations in force and by the product’s

approval. This flue can be identified by an identification mark and special distinctive marking bearing the note "only for con-

densation boilers".

For non-original flue system, refer to the technical data of the appliance.

The plastic pipes cannot be installed outdoors, for tracts longer than 40 cm, without suitable protection from UV rays and other

atmospheric agents.

Resistance factors and equivalent lengths

Each flue component has a Resistance Factor based on experimental tests and specified in the table in Paragraph 1.13..

The Resistance Factor for individual components is independent from the type of appliance on which it is installed and has a dimension-

less size.

It is however, conditioned by the temperature of the fluids that pass through the pipe and therefore, varies according to applications for

air intake or flue exhaust.

Each single component has a resistance corresponding to a certain length in metres of pipe of the same diameter; the so-called equivalent

length, can be obtained from the ratio between the relative Resistance Factors.

All boilers have an experimentally obtainable maximum Resistance Factor (R) equal to 100.

The maximum Resistance Factor allowed corresponds to the resistance encountered with the maximum allowed pipe length for each

type of Terminal Kit.

This information allows calculations to be made to verify the possibility of setting up various flue configurations.

To dimension the flue ducting using commercial components, refer to the table of combustion parameters (Par. 4.2).

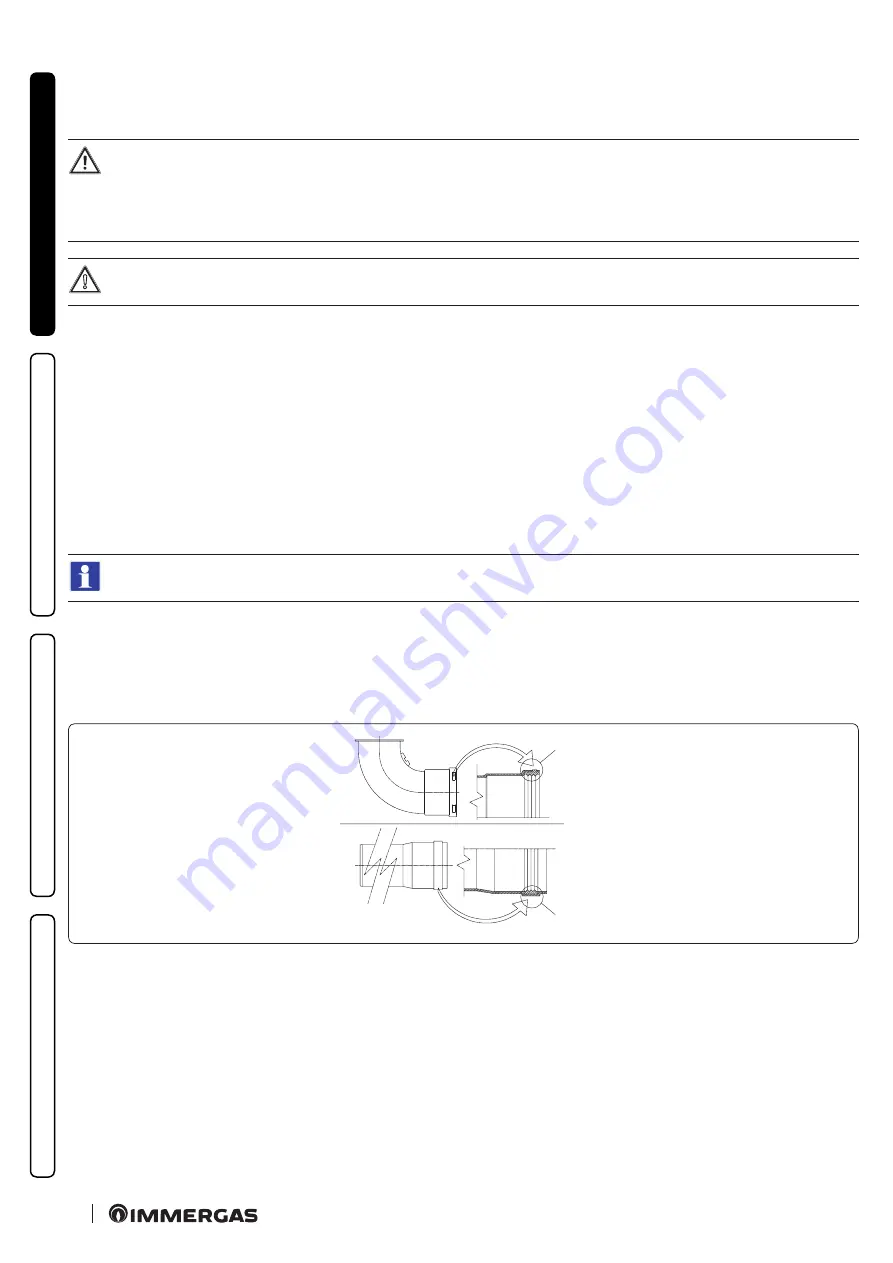

Positioning the gaskets (black) for “green range” flue systems.

Position the gasket correctly (for bends and extensions) (Fig. 12):

- gasket (A) with notches, to use for bends;

- gasket (B) without notches, to use for extensions.

If necessary, to ease the push-fitting, spread the elements with commonly-used talc.

A

B

12