33

INS

TALLER

U

SER

M

AINTEN

AN

CE

TECHNI

CI

AN

TECHNI

CAL

D

AT

A

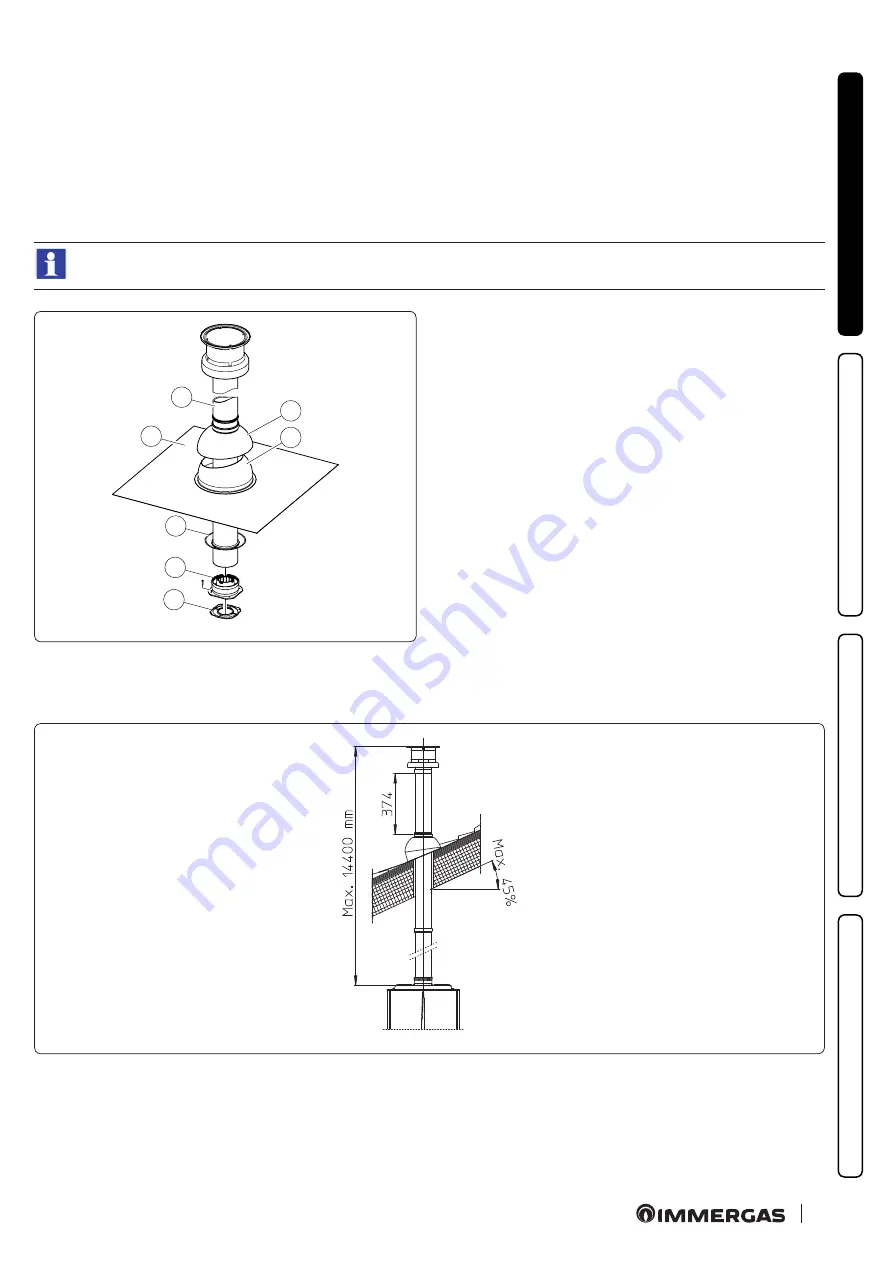

Mounting the vertical kit with aluminium tile Ø 60/100 (Fig. 22)

1. Install the concentric flange (2) on the central hole of the appliance, positioning gasket (1) with the circular projections downwards in

contact with the appliance flange.

2. Tighten the concentric flange with the screws in the kit.

3. Replace the tiles with the aluminium sheet (4), shaping it to ensure that rainwater runs off.

4. Position the fixed half-shell (6) on the aluminium tile.

5. Insert the intake-exhaust pipe (5).

6. Fit the Ø 60/100 concentric terminal pipe with the male side (5) (smooth) into the flange (2) up to the end stop, making sure that the

wall sealing plate has been fitted (3); this will ensure sealing and joining of the elements making up the kit.

When the appliance is installed in areas where very rigid temperatures can be reached, a special anti-freeze kit is available that

can be installed as an alternative to the standard kit.

C

33

7

4

6

5

1

2

3

22

The kit includes (Fig. 22):

N°1 Gasket (1)

N°1 Female concentric flange (2)

N°1 Wall sealing plate (3)

N°1 Aluminium tile (4)

N°1 Concentric intake/exhaust pipe Ø 60/100 (5)

N°1 Fixed half-shell (6)

N°1 Mobile half-shell (7)

Extensions for Ø 60/100 vertical kit (Fig. 23)

The kit with this configuration can be extended up to a max. vertical straight length of 14.4 m including the terminal. This configuration

corresponds to a resistance factor of 100. In this case specific extensions must be requested.

C

33

23