38

INS

TALLER

U

SER

M

AINTEN

AN

CE

TECHNI

CI

AN

TECHNI

CAL

D

AT

A

1

2

3

3

4 5

6 7

6

8

9

A

10

11

12

30

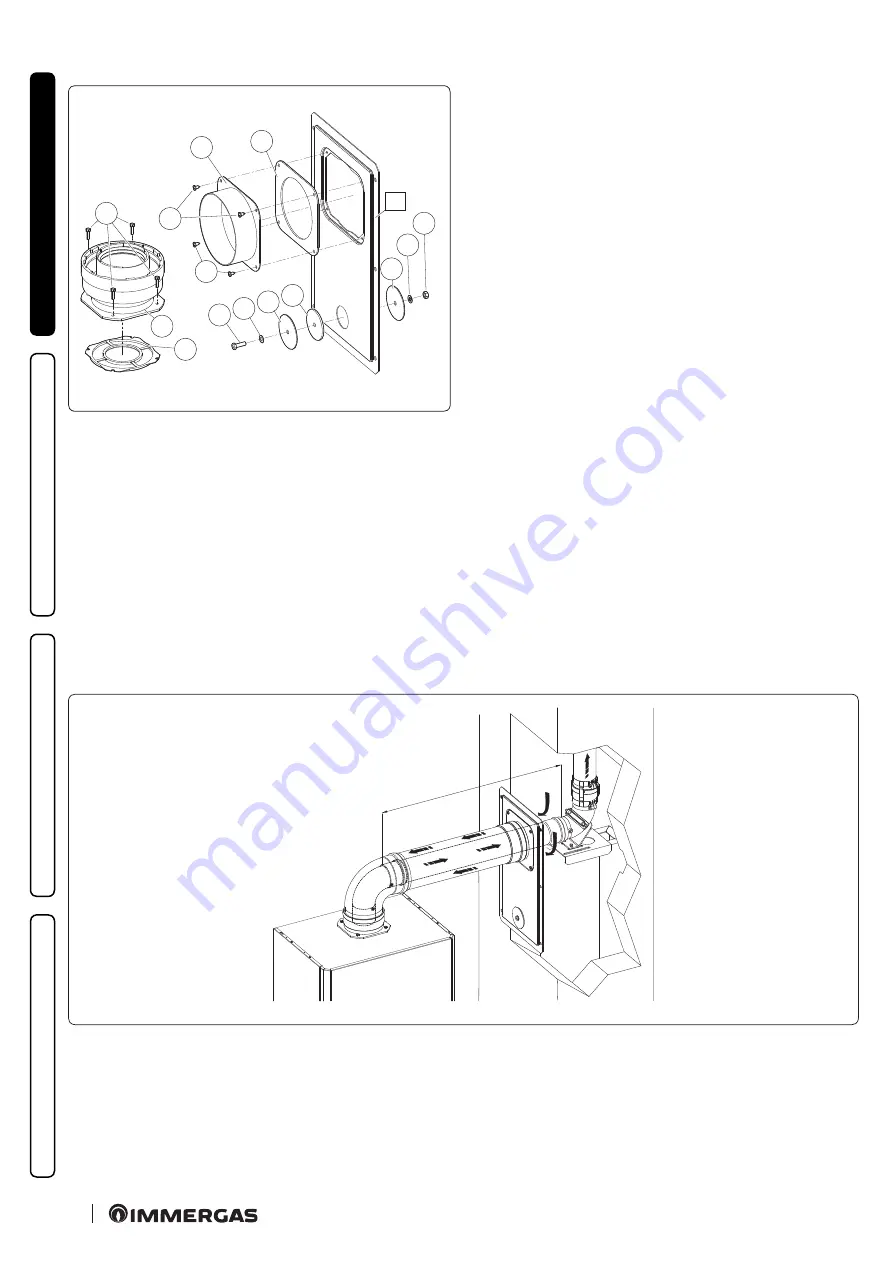

The adapter kit includes (Fig. 30):

N°1 Door adaptor Ø 100 or Ø 125 (1)

N°1 Door gasket made of neoprene (2)

N°4 Screws 4.2 x 9 AF (3)

N°1 Hex headed screw M6 x 20 (4)

N°1 Flat nylon washer M6 (5)

N°2 Door hole closure metal-sheet plate plug (6)

N°1 Plug gasket made of neoprene (7)

N°1 Toothed washer M6 (8)

N°1 Nut M6 (9)

N°1 (kit Ø 80/125) Concentric gasket Ø 60/100 (10)

N°1 (kit Ø 80/125) Flanged adapter Ø 80/125 (11)

N°4 (kit Ø 80/125) Hex headed screws M4 x 16 slotted screwdriver (12)

N°1 (kit Ø 80/125) Bag of lubricating talc

Supplied separately (Fig. 30):

N°1 Ducting kit door (A)

Technical data

The dimensions of the shafts must ensure a minimum gap between the outer wall of the smoke duct and the inner wall of the shaft: 30 mm

for circular section shafts and 20 mm in the event of a square section shaft (Fig. 29).

Maximum 2 changes of direction are allowed on the vertical section of the flue system with a maximum clearance angle of 30° with re-

spect to the vertical.

The maximum vertical extension using a Ø 60 ducting system is 13 m, the maximum extension includes 1 bend Ø 60/100 at 90°, 1 m of

horizontal pipe Ø 60/100, 1 x 90° Ø 60 ducted bend and the roof terminal for ducting.

Free

The maximum vertical extension using a Ø 80 rigid ducting system is 28 m, the maximum extension includes 1 adapter from Ø 60/100 to

Ø 80/125, 1 bend Ø 80/125 of 87°, 1 m of pipe Ø 80/125 in horizontal, 1 x 90° ducted bend Ø 80 and the roof terminal for ducting.

To determine the C

93

flue system in configurations other than that described (Fig. 31) one must consider the following head losses:

- 1 m of concentric pipe Ø 80/125 = 1.8 m of rigid ducted pipe Ø 80 and 0.7 m of flexible ducted pipe Ø 80;

- 1 curve Ø 80 of 87° = 2.1 m of rigid ducted pipe Ø 80 and 0.9 m of flexible ducted pipe Ø 80.

Consequently one must subtract the equivalent length of the part added to the 28 m available.

C

93

X

31