17

INS

TALLER

U

SER

M

AINTEN

AN

CE

TECHNI

CI

AN

TECHNI

CAL

D

AT

A

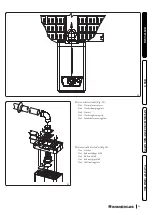

1.7 GAS CONNECTION

Our boilers are designed to operate with methane gas (G20) LPG and propane air (50% air - 50% propane). Power supply pipes must be the

same as or larger than the boiler fitting.

Before connecting the gas line, carefully clean inside all the fuel feed system pipes to remove any residue that could impair ap-

pliance efficiency.

Also make sure the gas corresponds to that for which the appliance is prepared (see appliance data nameplate).

If different, the boiler must be converted for operation with the other type of gas (see converting appliance for other gas types).

It is also important to check the dynamic pressure of the mains (methane or LPG) used to sup-

ply the boiler, which must comply with EN 437 and its attachment, as insufficient levels may

reduce generator output and cause discomfort to the user.

Static/dynamic network pressures higher than those required for regular operation may cause

serious damage to the appliance control elements; in this case shut the gas line off.

Do not operate the device.

Have the device checked by experienced personnel.

According to the local regulation in force, make sure that a gas cock is installed upstream of each connection between the appli-

ance and the gas system. This cock, if supplied by the appliance’s manufacturer, can be directly connected to the appliance (i.e.

downstream from the pipes connecting the system to the appliance), according to the manufacturer’s instructions.

The Immergas connection unit, supplied as an optional kit, also includes the gas cock, whose installation instructions are pro-

vided in the kit.

In any case, make sure the gas cock is connected properly.

The gas supply pipe must be suitably dimensioned according to current regulations in order to guarantee correct gas flow rate to the burn-

er even in conditions of maximum generator output and to guarantee appliance efficiency (technical specifications).

The coupling system must conform to standards in force (EN 1775).

The appliance is designed to operate with fuel gas free from impurities; otherwise it is advisable to fit special filters upstream of

the appliance to restore the purity of the fuel.

Storage tanks (in case of supply from LPG depot).

- New LPG storage tanks may contain residual inert gases (nitrogen) that degrade the mixture delivered to the appliance casing func-

tioning anomalies.

- Due to the composition of the LPG mixture, layering of the mixture components may occur during the period of storage in the tanks.

This can cause a variation in the calorific value of the mixture delivered to the appliance, with subsequent change in its performance.