Slew Drives

Installation and commissioning

23

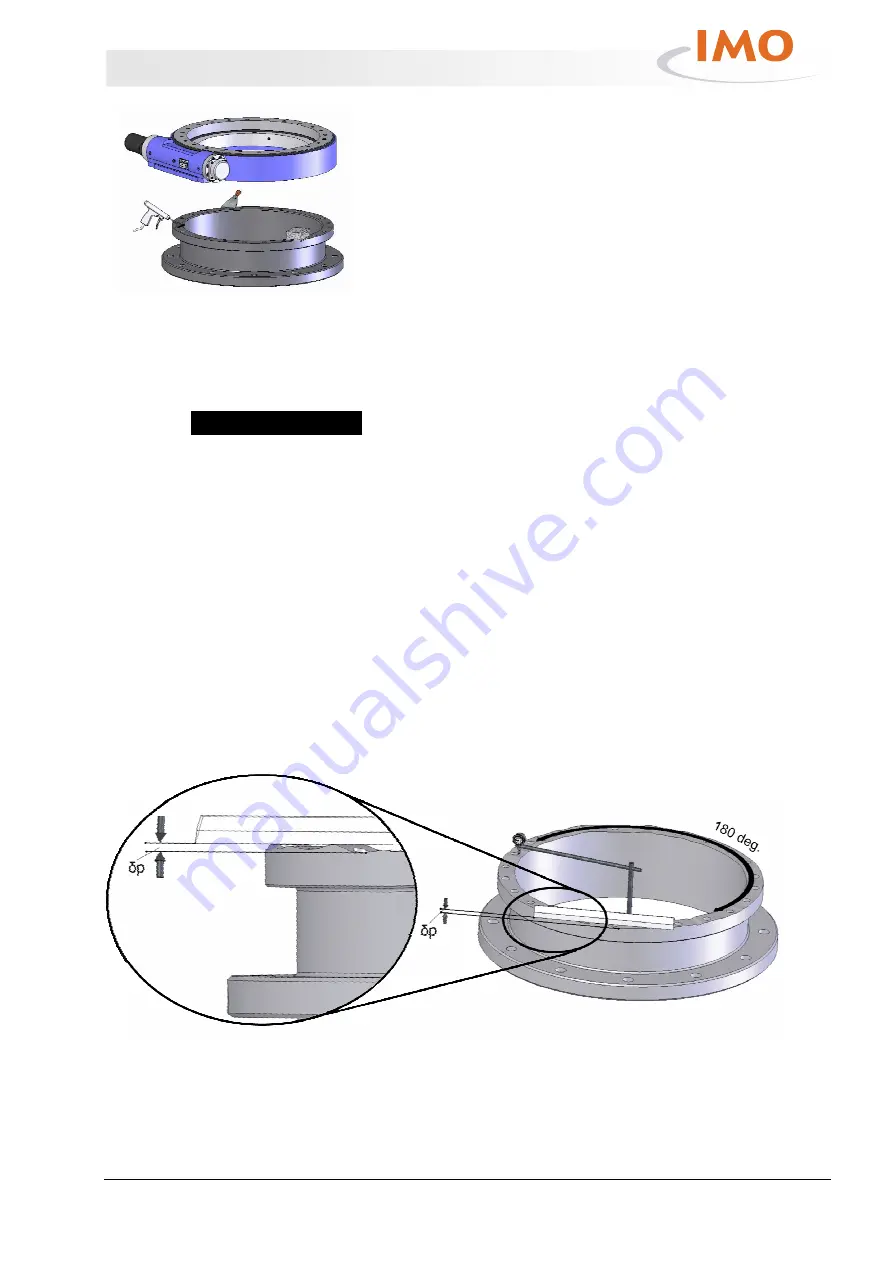

Fig. 12: Cleaning

When using cleaning agents, ensure adequate ventilation.

Maintain a strict ban on smoking.

Remove old grease, dust, and fouling with lint-free cloths.

Remove foreign material from the support surface of the

mounting structure (including paint residue, welding beads,

burrs).

If necessary clean the support surface of the slew drive.

Strictly comply with industrial safety regulations.

5.2.3

Determination of flatness deviation, and perpendicularity deviation and

deformation of the mounting structure

IMPORTANT

If there are impermissibly high deviations in flatness and

perpendicularity in the mounting structure, then rotational

resistance of the slew drive may significantly increase and

damage the entire slew drive. In the worst case the slew

drive may block.

If the permissible values for flatness or perpendicularity

deviation are exceeded, the mounting structure of the

slew drive shall be replaced or reworked.

Determination of flatness deviation, and perpendicularity deviation of the mounting structure

The mounting structure can be measured using a measuring plate

and dial gauges.

Laser processes and measuring with 3D systems have also proven

to be effective. These systems can be used without additional

auxiliary material, and they can document the actual gradient of

the mounting structure and process it accordingly.

Flatness deviation

Fig. 13: Flatness deviation