Slew Drives

Installation and commissioning

33

Tightening torque M

A

in ft-lbs with incremental tightening

Step 1

30%

Step 2

80%

Step 3

100%

Mounting bolt

dimensions

Tightening torque M

A

in ft-lbs

Strength class 10.9

M6

2.50

6.80

8.50

M8

6.20

16.5

20.7

M10

12.3

33.0

41.2

M12

21.6

57.6

72.0

M16

54.3

145

181

M20

107

284

355

M24

184

490

612

M30

368

980

1225

Tab. 14

Tightening torque M

A

in ft-lbs with incremental tightening

Step 1

30%

Step 2

80%

Step 3

100%

Mounting bolt

dimensions

Tightening torque M

A

in ft-lbs

Strength class SAE Grade 8

1/4 - 20 UNC

2.60

6.90

8.60

5/16 - 18 UNC

5.40

14.4

18.0

3/8 - 16 UNC

9.70

25.8

32.3

7/16 - 14 UNC

15.6

41.6

52.0

5/8 - 11 UNC

47.7

127

159

3/4 - 10 UNC

85.5

228

285

7/8 - 9 UNC

138

369

461

1 1/8 - 7 UNC

294

785

981

Tab. 15

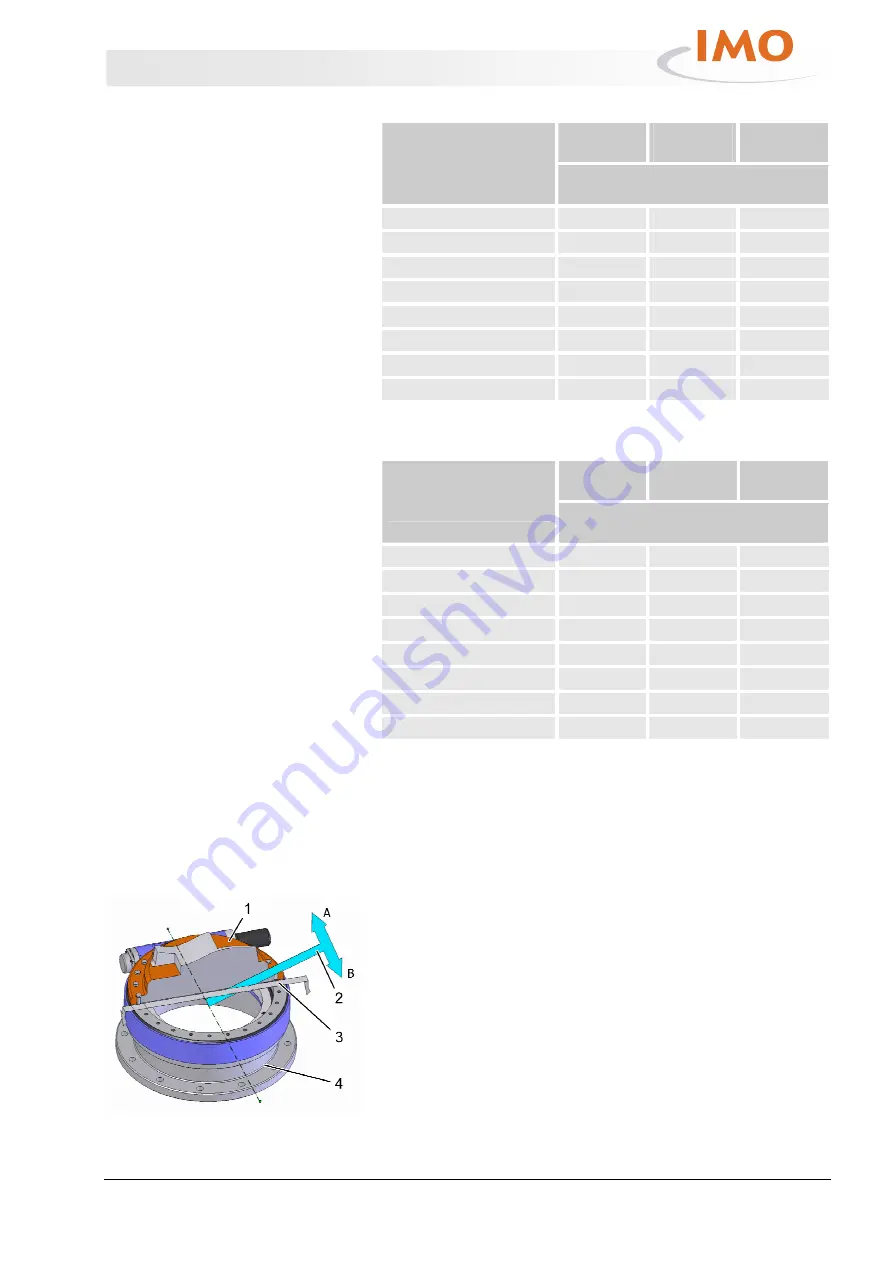

5.3.4

Determining the tilting clearance

Tilting clearance increases as raceway system wear increases. To

determine the increase in tilting clearance a basic measurement

must be executed in installed status and prior to first-time

operation. This is the only way to determine changes.

Fig. 23: Determine tilting clearance

1

Upper mounting structure

2

Tilting direction

3

Main load-carrying zone

4

Lower mounting structure