Slew Drives

Maintenance

40

Checking the tilting clearance increase

d

k

directly on the

slew drive

The measured value m1 determined at installation serves as the

base value (

section 5.3.4 "Determination of tilting clearance").

Determine the value mx as described in the section 5.3.4

"Determining the tilting clearance".

Subtract the base value m1 from the value mx determined in

the inspection measurement:

Checking the tilting clearance increase

d

k

but not directly

on the slew drive

Proportionally convert the tilting clearance increase each time a

measurement is taken (after the installation measurement ) and

compare with

d

k

perm.

6.4.3

Checking the circumferential backlash

CA

CA

CA

CAUTION

UTION

UTION

UTION

Toothing wear causes increased circumferential backlash.

When the maximum permissible circumferential backlash

is reached, then the system must be brought to a standstill

and the slew drive must be replaced immediately, as safe

operation can no longer be ensured.

1.

Determine the circumferential backlash in accordance with

5.3.5 "Determining the circumferential backlash".

2.

Compare the determined value with the permissible values of

the table.

See the type plate for the module specification.

For a module that is between the specified values, use the

value for the smaller module.

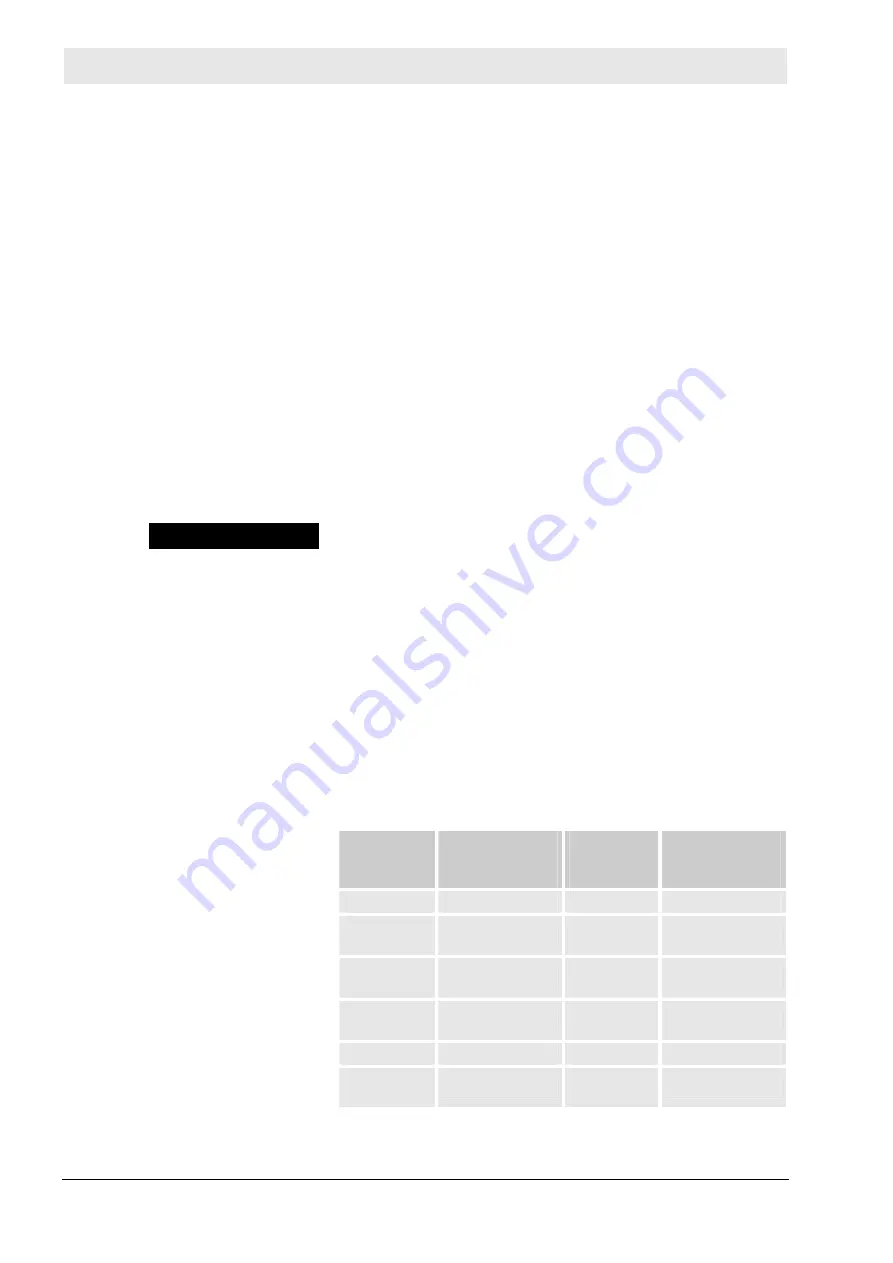

Circumferential backlash angle limit values

Module of

the

toothing

Limit of

circumferential

backlash angle

Module of

the

toothing

Limit of

circumferential

backlash angle

3

34°

6

28°

4

32°

6/2

convolution

14°

4/2

convolution

16°

7

28°

4,5

31°

7/2

convolution

14°

5

30°

8

27°

5/2

convolution

15°

8/2

convolution

13.5°

Tab. 18

d

k

= mx – m1 ≤

d

k

perm

d

k

perm = 0.45 mm

d

k

perm = 0.0177 in