Slew Drives

Maintenance

41

6.4.4

Lubricating the slew drive

IMPORTANT

Regularly lubricate the slew drives to prolong their service

life and ensure safe operation.

IMPORTANT

Always use the lubricants specified in the order drawing. If

using other lubricants pay attention to the relative

mixability of the substances. The standard lubricants used

are "r.tecc Norplex LKP2" from Rhenus, or the grease

"Optimol Longtime PD0" from Castrol. If in doubt, or if

there is no specification on the drawing, consult with our

customer service (

page 2). Using the wrong lubricant

may cause damage to the slew drives and reduce the

service life. In this case, any warranty shall be excluded.

Comply with the instructions provided by the lubricant

manufacturer!

If possible use a central lubrication system to lubricate the

raceway system. In this regard ensure that the hoses are filled

with grease at commissioning and that the storage tanks are

regularly topped up with grease.

An automatic re-lubricating system significantly facilitates re-

lubrication for the raceway system and the toothing. Functional

safety as well as wear behavior are improved.

Comply with the instructions in the operating manual provided

by the respective manufacturer for lubrication of optional

intermediate gear units, brakes, and motors.

If it is evident that moisture has penetrated into the slew drive,

or has been absorbed by the grease, you must re-lubricate

more intensively.

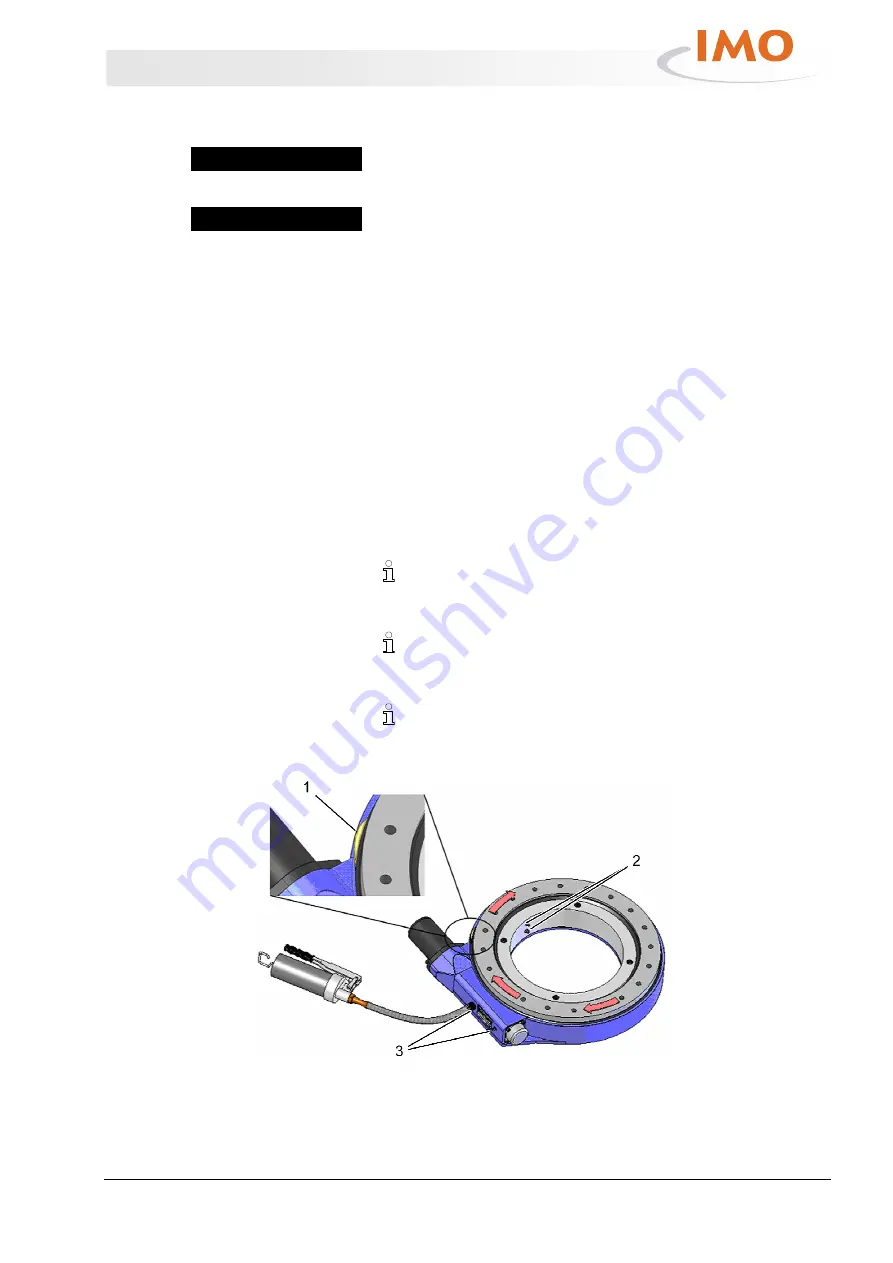

Fig. 26: Lubricating the slew drive

1

Fresh lubricant

2

Lubricating nipple, bearing ring

3

Lubricating ring housing