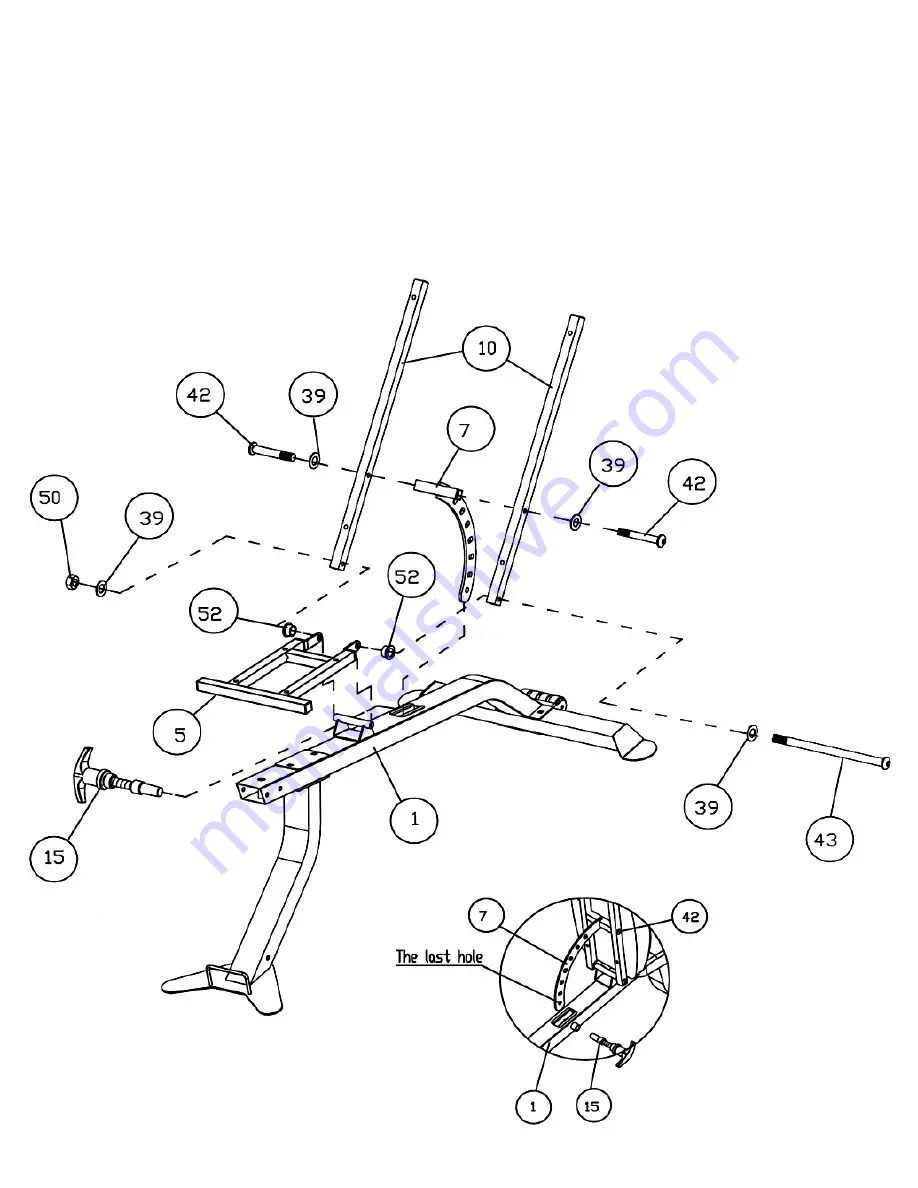

STEP 4 (See Diagram 4)

A.) Insert two Ø ½” Bushings (#52) into the holes on the Seat Bracket (#5) and align the holes to

the pivot on the Main Seat Support (#1).

B.) Attach the two Backrest Supports (#10) to the Seat Bracket and align the holes. Secure them

with a M10 x 7 ¼” Allen Bolt (#43), two Ø ¾” Washers (#39), and one M10 Aircraft Nut (#50). Do

not over tighten the Nut and Bolt. Make sure the Backrest Supports are able to swivel.

C.) Attach the Backrest Incline Support (#7) to the opening on the Main Seat Support. Use the T-

shaped Lock Pin (#15) to secure the Backrest Incline Support at the Last Hole on the end of

Support.

D.) Attach the other end of the Backrest Incline Support (#7) to the Backrest Supports (#10). Align

the holes and secure them with two M10 x 1 ¾” Allen Bolts (#42) and two Ø3/4” Washers (#39).

27

Summary of Contents for IGS-5100

Page 5: ...SMITH MACHINE HARDWARE PACK 4 ...

Page 6: ...SMITH MACHINE HARDWARE PACK 5 ...

Page 7: ...SMITH MACHINE HARDWARE PACK 6 ...

Page 8: ...SMITH MACHINE HARDWARE PACK 7 ...

Page 10: ...DIAGRAM 1 9 ...

Page 13: ...DAIGRAM 3 12 ...

Page 15: ...CABLE LOOP DIAGRAM 14 ...

Page 19: ...DIAGRAM 7 18 ...

Page 21: ...EXPLODED DIAGRAM 20 ...

Page 23: ...MULTI PURPOSE BENCH HARDWARE PACK 22 ...

Page 24: ...MULTI PURPOSE BENCH HARDWARE PACK 23 ...

Page 31: ...30 ...