14

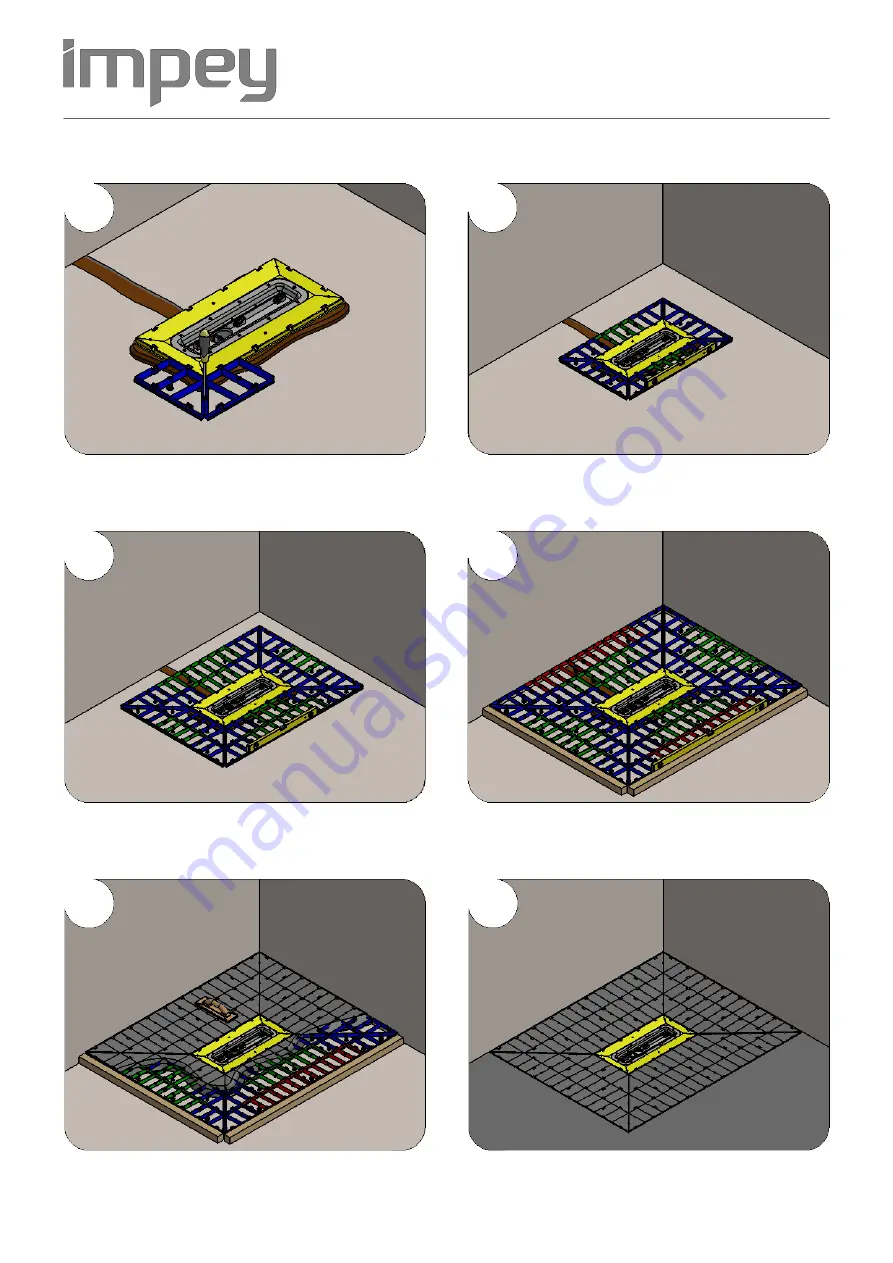

Working in a clockwise direction continue to add parts.

After completion of each row the outer edges must be

level.

15

Continue adding parts and levelling in the same manner.

16

When the assembly is complete we recommend that the

outer perimeter is shuttered to prevent screed escaping

whist backfilling is carried out.

17

Begin filling the Aqua-grade with a semi dry screed mix and

smooth off with a wooden or plastic float.

Ensure the screed is compacted well to prevent hollow areas.

18

When fully filled it may be necessary to allow the screed

to dry out slightly before final finish trowelling.

When complete the shuttering can be removed and the

remaining floor finished.

13

When the first section has been adjusted continue adding

the remaining components for the configuration you are

installing. Follow the relevant assembly diagrams in section 5.

Section 4, General Installation guidance

for all configuration types

This section covers parts of the installation that are are common to all configuration types.

Please see section 5 and follow the relevant stages that are applicable to the type you are installing.

Page 7