6

10. Adjust the speed of this function by using the

program "T-O-T" toggle switch (momentary - zero

- momentary). Push the toggle switch toward "+"

to increase speed, toward "-" to decrease speed.

Adjust the function speed to move as slowly as

possible. This helps to achieve a smooth start

when this function is activated.

11. To set maximum speed - Deflect the joystick to its

maximum position. Push the program toggle

switch toward "+" to increase speed, toward "-" to

decrease speed.

The receiver can program only one function at a time.

Make sure that only one axis is deflected at a time.

When function adjustment is complete in one direction,

repeat the procedure above for the other directions and

functions. Remember to set values for both high and

low ranges.

After all adjustments are complete, wait at least 10

seconds before turning the transmitter off. The new

values will be automatically stored into the system’s

memory.

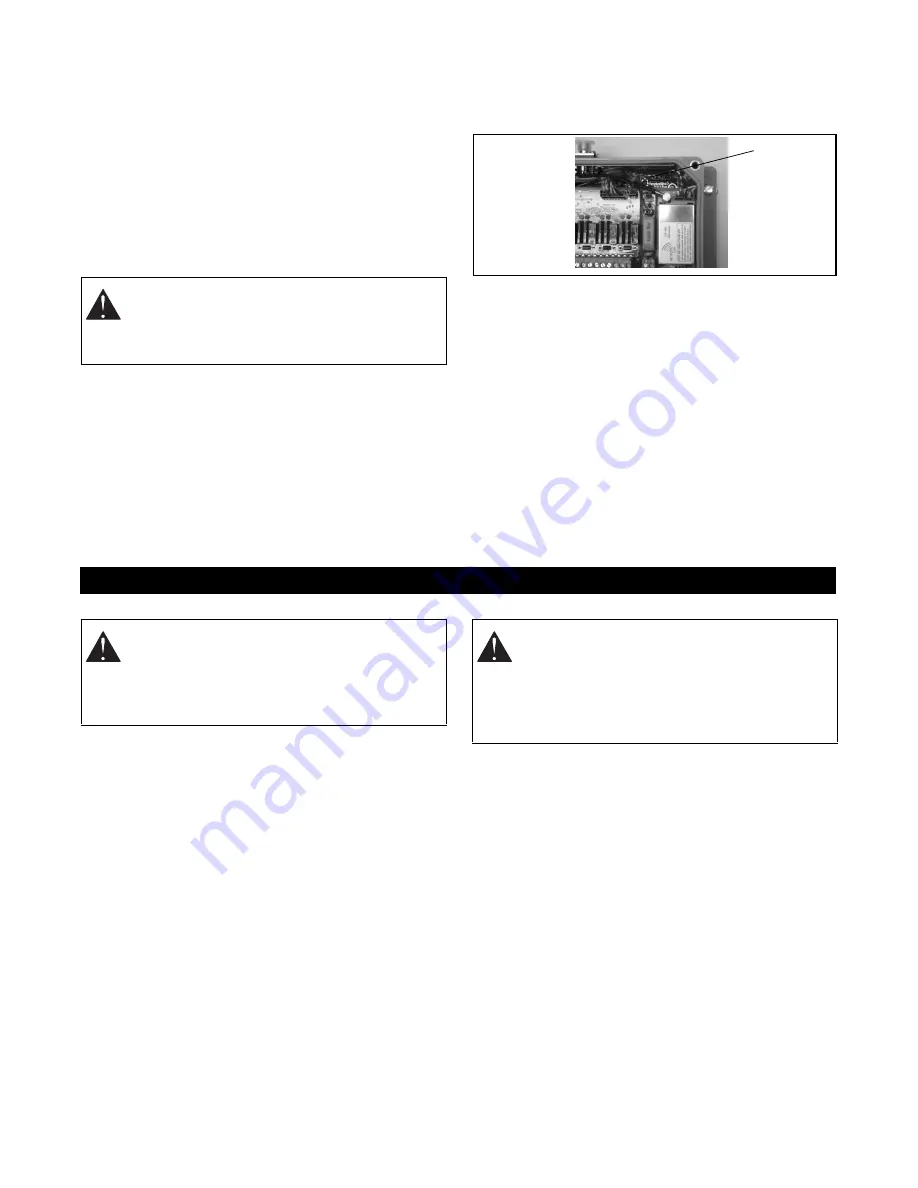

If problems occur during the adjustment procedure,

you can revert to the default values of the system.

Remove the receiver lid and press the reset button on

the board. Reinstall the receiver lid.

ADDRESS SETTINGS

The address settings are pre-set at the factory in the

ADMO module. However, if the transmitter coder

board, the BMS-1 Base Board, or if the entire

transmitter or receiver are replaced, the ADMO

address must match the system.

IMPORTANT:

If the ADMO settings of the transmitter

and receiver do not match, the system will not function.

The safety checks as described in the following

paragraphs must be completed before the radio remote

control system is activated. These checks must be

performed at least once a day, before the start of any

operation and at all shift changes.

IMPORTANT:

A transmitter drawing is included with

each system. Transmitter layout and inscriptions may

vary according to customer requests. In most cases,

however, the inscriptions are identical to that of the

present control. The only difference is that the machine

is controlled without a cable control. Consult the

machine manufacturer’s operator manual and the

transmitter drawing for additional information on the

arrangement of the transmitter’s operating elements

and their corresponding functions. The following

description refers to the control elements and specific

functions of the radio remote control.

VISUAL CHECK

Always check the transmitter for any physical damaged

before any operation.

• Always keep safety features, guards and controls

in good repair, in place and securely fastened.

• Check equipment for wear or damage.

• Check rubber cuffs and pushbutton caps for wear

or damage.

IMPORTANT:

Never operate a transmitter with worn or

damaged parts. Replace immediately with only

authorized

parts. Contact

IMT

or your Dealer.

START-UP PROCEDURE

This procedure must be carefully followed before

beginning any operation.

WARNING:

AVOID INJURY - The crane is

moving during the adjustment of the

functions. Be sure the work area is clear of

obstacles and bystanders.

Reset

Button

BMS_0010

Figure 7

OPERATION

WARNING:

FAILURE TO FOLLOW

INSTRUCTIONS could result in personal

injury and/or damage to equipment. Read and

understand the safety instructions in all

manuals provided.

WARNING:

FAILURE TO FOLLOW

INSTRUCTIONS could result in personal

injury and/or damage to equipment. Test the

"EMERGENCY STOP" function as described

in the machine manufacturer’s operator

manual before beginning any operation.

Summary of Contents for 16000-SIII

Page 13: ......