7

1. Be sure that all safety measures required by the

equipment manufacturer have been followed. (i.e.

crane level, stabilizers down, etc.)

2. Push in the transmitter E-stop pushbutton.

3. Switch the transmitter "ON". A short buzzer signal

will sound.

4. Wait for the second buzzer signal (approx. 3

seconds).

5. The green LED on the transmitter control panel

will flash.This indicates that the transmitter is

working and is ready to use.

6. Pull out the E-stop pushbutton.

7. Push the green pushbutton "Start/horn" on the

transmitter.

8. Check that the machine functions correspond

with the transmitter functions.

IMPORTANT:

The machine functions will operate

during this check. Be certain that there are no

obstacles near the machine.

9. Push the "EMERGENCY STOP" pushbutton on

the transmitter. Be sure that no functions can be

activated with the "EMERGENCY STOP"

pushbutton depressed.

IMPORTANT:

If any function of the radio remote

control activates with the "EMERGENCY STOP"

engaged, the radio remote control must not be used

until it is repaired.

10. Pull out the "EMERGENCY STOP" pushbutton.

11. Push the green pushbutton "Start/horn" on the

transmitter.

12. Both the radio remote control and the machine

are now ready for operation.

IMPORTANT:

To avoid accidental start-up, always

engage the E-stop pushbutton and switch the

transmitter "OFF" when not in use. When the

transmitter is not attached to the operator, the key

switch should be removed and stored in a secure

place.

SPEED CONTROL

This radio remote control system is equipped with a

dual range speed control. The switch allows selection

between high range (rabbit) and low range (snail). The

low range provides <70% of full speed.

PROPORTIONAL FUNCTIONS

The proportional functions and speed ranges are

pre-set by

IMT

according to the valve types. Your

dealer can refer to the basic adjustments at any time.

Only the crane manufacturer, dealer or authorized

service representative is allowed to adjust individual

functions, direction and speed range.

OPTICAL DISPLAYS AND ACOUSTIC

SIGNALS

The radio remote control system uses optical displays

and acoustic signals to show current working status.

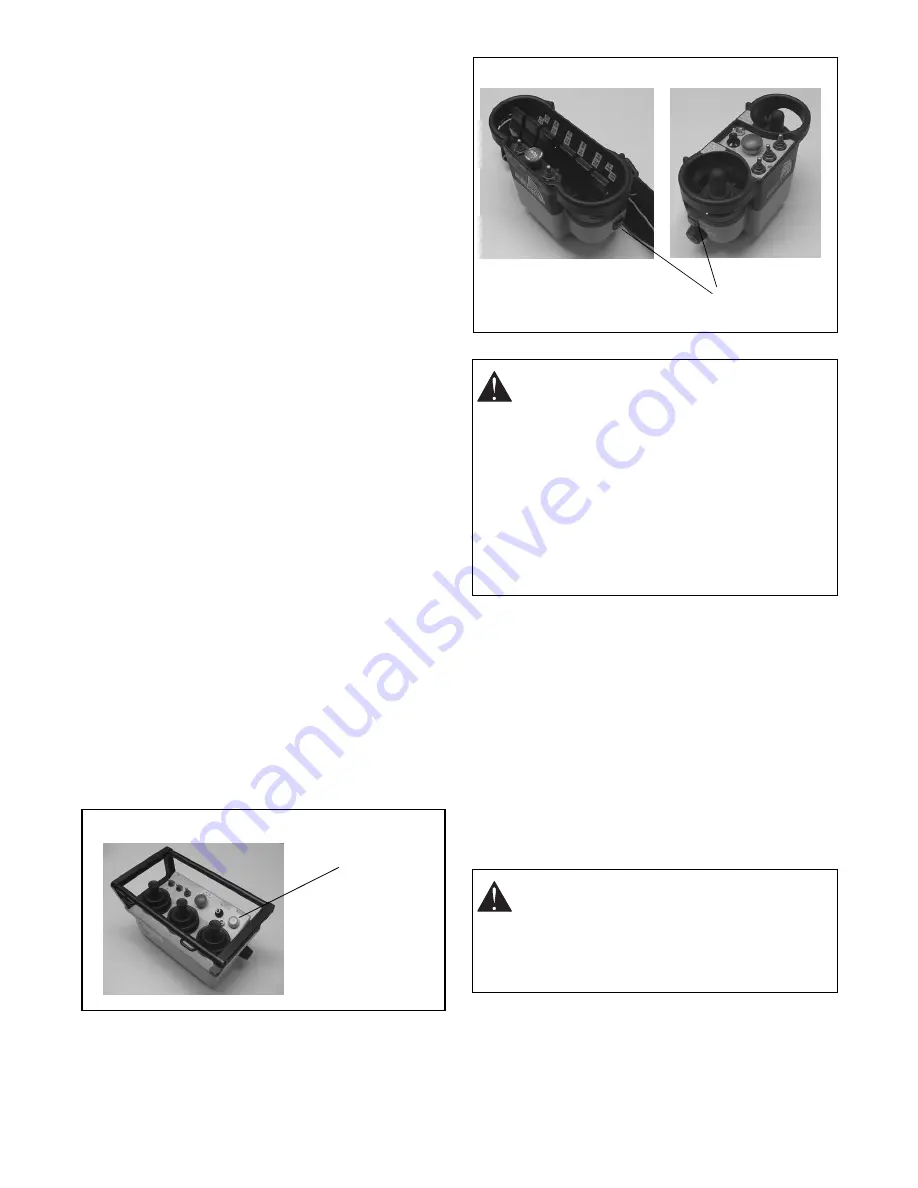

GL-2

GL2_0020

Start

Pushbutton

Figure 8

WARNING:

TO AVOID SERIOUS INJURY

OR DEATH. Switch the machine "OFF" if

there is a fault or any problems with the safety

check. Contact

IMT

or your dealer

immediately to repair the system. NEVER

operate the machine when the

"EMERGENCY STOP" function does not

operate properly.

Improper operation, maintenance or

adjustment may cause serious injury or

damage to equipment and may void the

warranty.

CAUTION:

DO NOT OPEN THE RECEIVER.

All relay and proportional outputs are

accessible on the connection plug.

Unauthorized entry into the receiver could

result in damage to equipment and may void

the warranty.

Nova-L

NVL_0010

NVL_0020

Start

Pushbuttons

Figure 9

Summary of Contents for 16000-SIII

Page 13: ......