Chapter 4 Maintenance & Repair

29

Electric Crane Lubrication

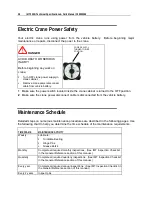

Different lubricants are required for different sections of your crane. Contact your lubricant

supplier for specific product information.

Follow the grease and lubricant specifications and intervals listed in this manual for best results.

APPLICATION POINT

LUBRICATION PRODUCT

APPLICATION METHOD

INTERVAL

Turntable Bearing (rotate

while greasing)

Cylinder Pins

Boom Hinge Pins

Shell Alvania 2EP or

Shell Retinax "A" or

Mobilith AW2 or

equivalent

Hand Grease Gun or

Pneumatic Pressure

Gun

Weekly

Gearbox bearings

Lithium or GP bearing

lube

Grease gun

Every 50 hours

Grease Zerks

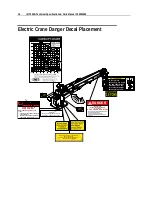

Crane grease zerks must be greased on a weekly basis during normal operating conditions.

Under severe operating conditions the zerks must be greased more frequently. Each grease

zerk is marked with a decal, “Grease Weekly”, as shown.

Crane worm gear teeth and bearing teeth must be lubricated weekly with Molub-Alloy 882 Heavy

or equivalent. See chart for the lubrication product schedule. Apply products with a grease gun

or brush as directed.

Summary of Contents for 2003i

Page 2: ......

Page 6: ......

Page 38: ......

Page 77: ...Chapter 8 General Reference 75 X R CA ITEM EXPLANATION DATE CORRECTED ...