Chapter 4 Maintenance & Repair

35

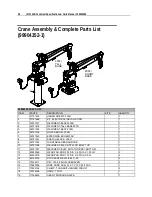

BOOM & MAST ASSEMBLY

1

Check control valvebank and all other fittings for oil leaks and tightness.

2

Check all bolts and retainer plates on pin assemblies for proper installation.

3

Check torque on all unit mounting bolts. See the installation drawing in the crane parts

manual for mounting bolt torque.

4

Check for loose bolts, fatigue cracks or corroded structural members.

BASE ASSEMBLY

1

Check base casting housing for cracks.

2

Check for proper rotation function by making several start-stop operations. Maximum

allowable free-play at mast front should be 3.2 mm (1/8") to 4.8 mm (3/ 16").

3

Check for proper gear mesh in turntable gear-bearing. Check motor and gear-mounting

bolts for tightness.

HYDRAULIC SYSTEM

1

CYLINDERS

a) Check rods for damage such as scarring, nicks, dents and rust on out-of-service units.

b) Check for leaks at weld joints and rod seals. Check for drift indicating leakage around

piston rings or defective holding valves.

c) Check extension cylinder head and piston positions.

d) Check cylinder case for dents.

2

HYDRAULIC POWER UNIT

a) Check for leaks at shaft seal.

b) Check for drop in operating speed.

c) Check hydraulic oil for excessive heating.

d) Check bolts and fasteners for tightness.

e) Note any unusual vibration or noise.

Summary of Contents for 2003i

Page 2: ......

Page 6: ......

Page 38: ......

Page 77: ...Chapter 8 General Reference 75 X R CA ITEM EXPLANATION DATE CORRECTED ...