70

IMT 2003i Technical Specifications & Parts Manual # 99904385

TYPE OF INSPECTION

NOTES:

Daily and monthly inspections are to be performed by a “competent person”, who is capable of identifying existing

and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to

employees, and who has authorization to take prompt corrective measures to eliminate them.

Quarterly and annual inspections are to be performed by a “qualified person” who, by possession of a recognized

degree, certificate, or professional standing, or who by extensive knowledge, training and experience, successfully

demonstrated the ability to solve/resolve problems relating to the subject matter, the work, or the project.

One hour of normal crane operation assumes 20 complete cycles per hour. If operation exceeds 20 cycles per hour,

inspection frequency should be increased accordingly.

Consult Operator / Service Manual for additional inspection items, service bulletins and other information.

Before inspecting and operating crane, crane must be set up away from power lines and leveled with stabilizers fully

extended.

DAILY (D): Before each shift of operation, those items designated with a (D) must be inspected.

MONTHLY (M): Monthly inspections or 100 hours of normal operation (whichever comes first) includes all daily

inspections plus items designated with an (M). This inspection must be recorded and retained for a minimum of 3

months.

QUARTERLY (Q): Every three to four months or 300 hours of normal operation (whichever comes first) includes all

daily and monthly inspection items plus items designated with a (Q). This inspection must be documented,

maintained, and retained for a minimum of 12 months, by the employer that conducts the inspection.

ANNUAL (A): Each year or 1200 hours of normal operation (whichever comes first) includes all items on this form

which encompasses daily, monthly and quarterly inspections plus those items designated by (A). This inspection

must be documented, maintained, and retained for a minimum of 12 months, by the employer that conducts the

inspection.

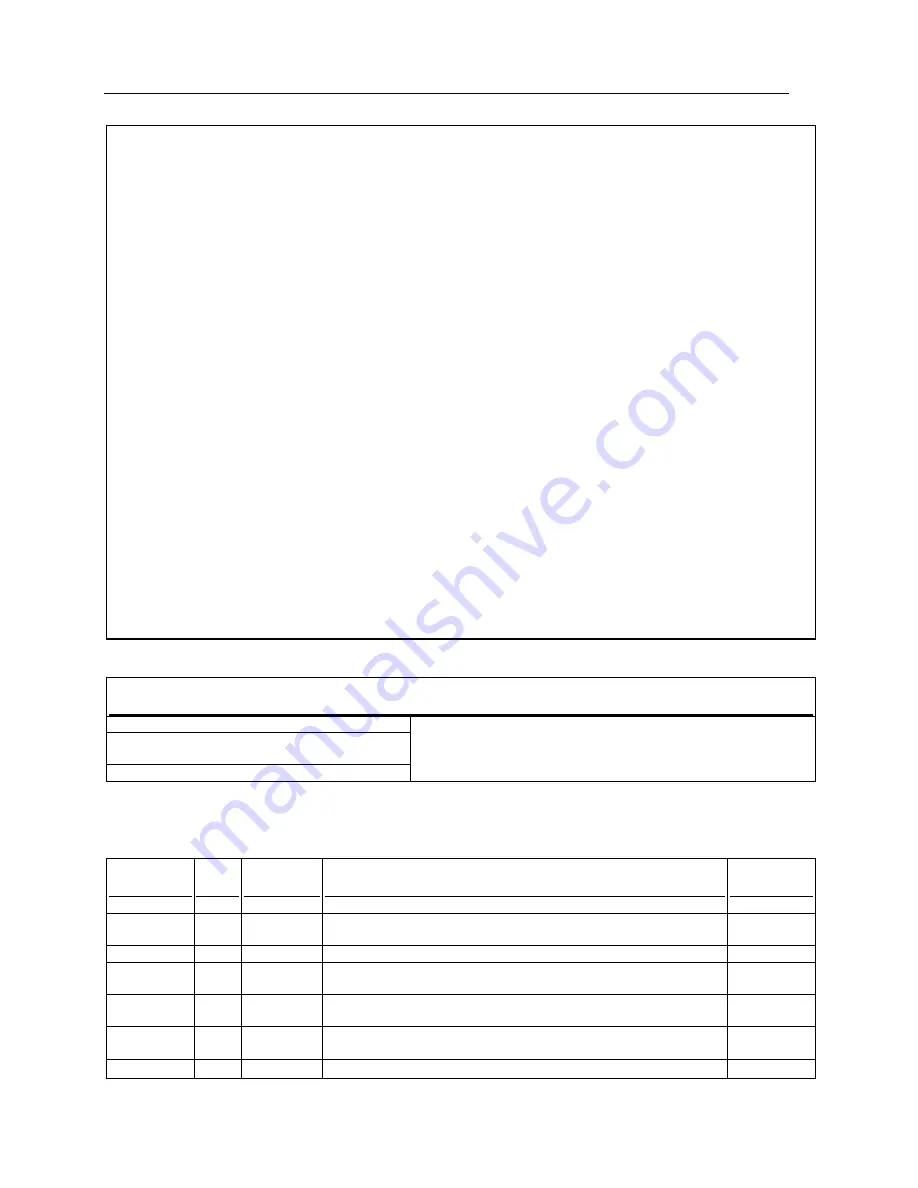

INSPECTION CHECKLIST STATUS KEY:

S = Satisfactory

X = Deficient

(NOTE: If a deficiency is found, an immediate determination must

be made as to whether the deficiency constitutes a safety hazard

and must be corrected prior to operation.)

R = Recommendation

(Should be considered for corrective action)

NA = Not Applicable

FREQUENCY ITEM KEY

INSPECTION DESCRIPTION

STATUS

(S,R,X,NA)

D

1

Labels

All load charts, safety & warning labels, and control labels are

present and legible.

D

2

Crane

Check all safety devices for proper operation.

D

3

Controls

Control mechanisms for proper operation of all functions, leaks

and cracks.

D

4

Station

Control and operator's station for dirt, contamination by lubricants,

and foreign material.

D

5

Hydraulic

System

Hydraulic system (hoses, tubes, fittings) for leakage and proper oil

level.

D

6

Hook

Presence and proper operation of hook safety latches.

Summary of Contents for 2003i

Page 2: ......

Page 6: ......

Page 38: ......

Page 77: ...Chapter 8 General Reference 75 X R CA ITEM EXPLANATION DATE CORRECTED ...