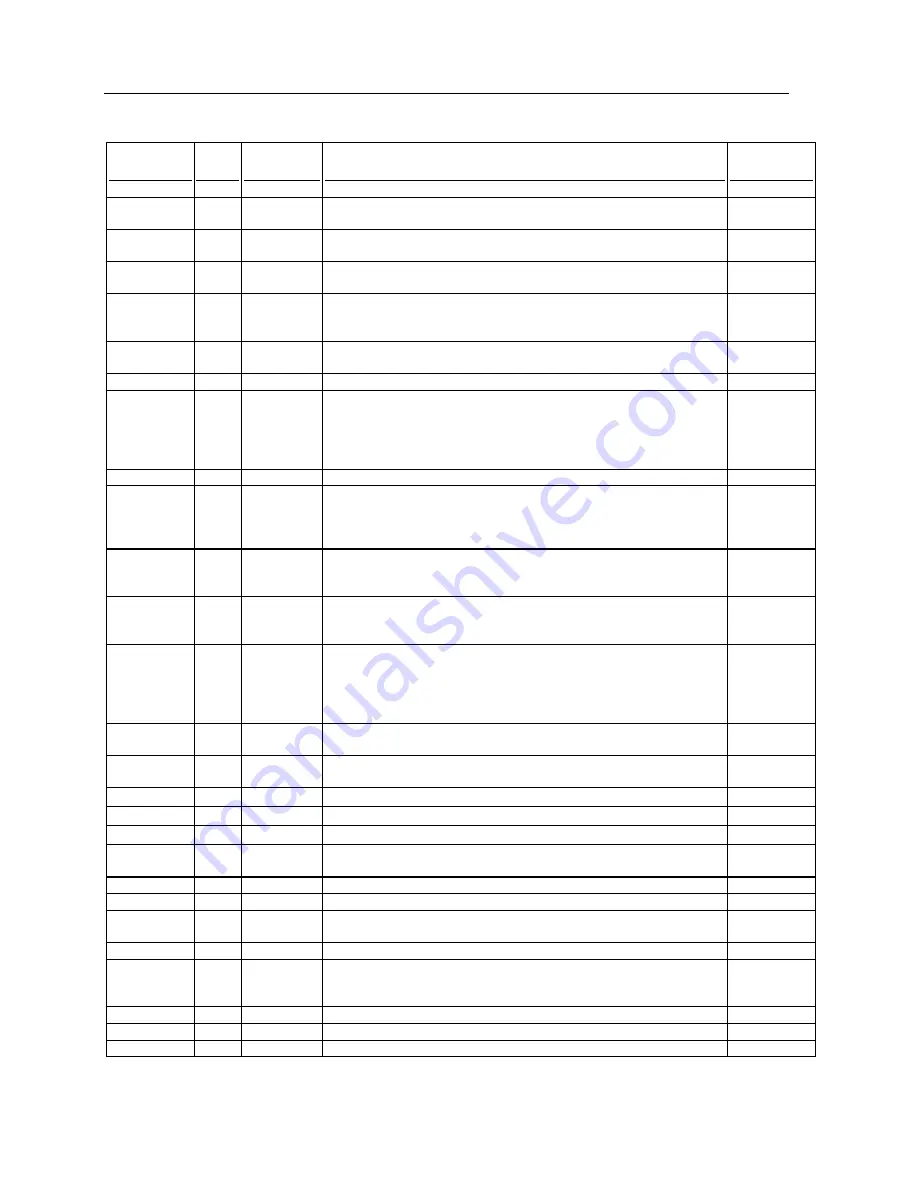

Chapter 8 General Reference

71

FREQUENCY ITEM KEY

INSPECTION DESCRIPTION

STATUS

(S,R,X,NA)

D

7

Wire Rope

Inspect for apparent deficiencies per applicable requirements and

manufacturer’s specifications.

D

8

Pins

Proper engagement of all connecting pins and pin retaining

devices.

D

9

General

Overall observation of crane for damaged or missing parts,

cracked welds, and presence of safety covers.

D

10

Operation

During operation, observe crane for abnormal performance,

unusual wear (loose pins, wire rope damage, etc.). If observed,

discontinue use and determine cause and severity of hazard.

D

11

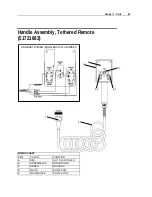

Remote

Ctrl

Operate remote control devices to check for proper operation.

D

12

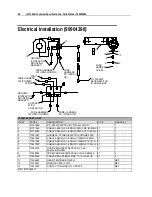

Electrical

Operate all lights, alarms, etc. to check for proper operation.

D

13

Anti Two-

Block or

Two-Block

Damage

Prevention

Operate anti two-block or two-block damage prevention device to

check for proper operation.

D

14

Tires

Check tires (when in use) for proper inflation and condition.

D

15

Ground

Conditions

Check ground conditions around the equipment for proper

support, watching for ground settling under and around stabilizers

and supporting foundations, ground water accumulation, or similar

conditions.

D

16

Level

Check the equipment for level position within the tolerances

specified by the equipment manufacturer’s recommendations,

both before each shift and after each move and setup.

D

17

Operator

cab

windows

Check windows for cracks, breaks, or other deficiencies which

would hamper the operator's view.

D

18

Rails, rail

stops, rail

clamps and

supporting

surfaces

Check rails, rail stops, rail clamps and supporting surfaces when

the equipment has rail traveling.

D

19

Safety

devices

Check safety devices and operational aids for proper operation.

D

20

Electrical

Check electrical apparatus for malfunctioning, signs of apparent

excessive deterioration, dirt or moisture accumulation.

D

21

Other

D

22

Other

M

23

Daily

All daily inspection items.

M

24

Cylinders

Visual inspection of cylinders for leakage at rod, fittings, and

welds. Damage to rod and case.

M

25

Valves

Holding valves for proper operation.

M

26

Valves

Control valves for leaks at fittings and between stations.

M

27

Valves

Control valve linkages for wear, smoothness of operation, and

tightness of fasteners. Relief valve for proper pressure settings.

M

28

General

Bent, broken, or significantly rusted/corroded parts.

M

29

Electrical

Electrical apparatus for malfunctioning, signs of apparent

excessive deterioration, dirt or moisture accumulation. Electrical

systems for presence of dirt, moisture, and frayed wires.

M

30

Structure

All structural members for damage.

M

31

Welds

All welds for breaks and cracks.

M

32

Pins

All pins for proper installation and condition.

Summary of Contents for 2003i

Page 2: ......

Page 6: ......

Page 38: ......

Page 77: ...Chapter 8 General Reference 75 X R CA ITEM EXPLANATION DATE CORRECTED ...