Maintenance & Repair

49

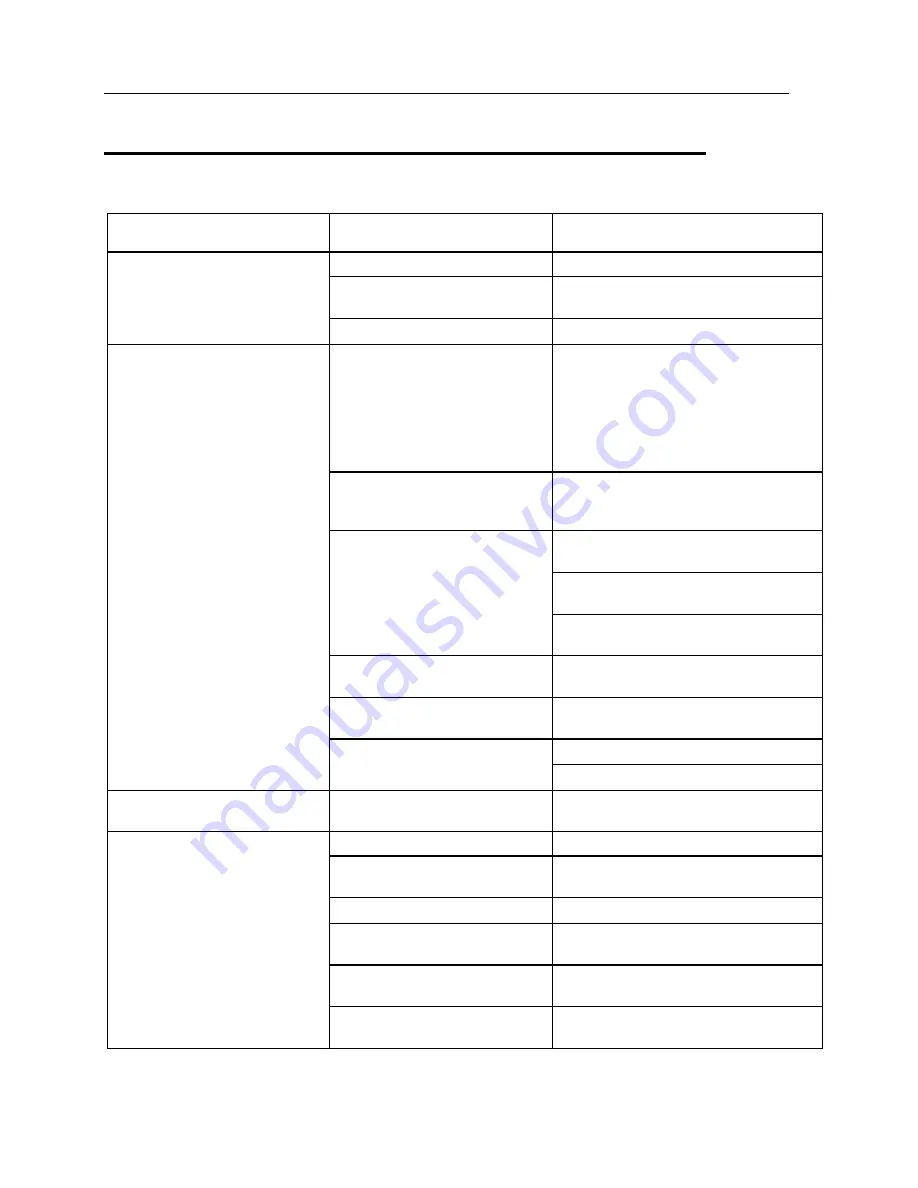

Compressor Troubleshooting

PROBLEM

CAUSE

RESOLUTION

Compressor does not make air. Air tank drain open.

Close tank drain valve.

Blow down valve stuck.

Remove blow-down valve, clean

out, reassemble.

PTO not engaged.

Engage PTO per instructions.

Compressor/truck shuts down. High air end temperature.

Check oil level. Add as required

per filling instructions. Do not

overfill. Wait for compressor to cool

down. Restart truck and

compressor. If truck shuts down

again, continue with

troubleshooting.

Fan not operating.

Insure that cooling fan is operating.

If not, check fuse in harness. See

speed control troubleshooting.

Air flow.

Insure that cooler has no airflow

obstructions.

Check air cooler core. Clean as

needed.

High ambient air temperature.

Contact IMT Technical Support.

Leaks.

Check for air leaking from tank or

blow down fittings.

Safety System Failure

Check high temperature shut down

circuitry for proper operation.

Oil flow restricted.

Check oil filter head for blockage.

Check for cold (< 0º F) oil.

Erratic speed. (Compressor

revs, slows, then dies.)

Low oil.

Check oil, and add if needed.

Low system pressure.

Air tank drain open.

Close tank drain valve.

Dirty air filter.

Check filter condition. Replace as

required.

Air leak.

Check air system fittings.

Pressure control valve stuck.

Remove, disassemble, clean.

Reassemble and install.

Inlet valve not fully open.

Inspect and repair. Check control

system operation.

System demands exceed

compressor delivery.

Reduce air demand and/or

consumption.

Summary of Contents for CAS2545

Page 2: ......

Page 6: ......

Page 15: ...Section 1 Compressor Introduction 13 CAS2545 Performance Charts...

Page 16: ...14 IMT CAS2545 Air Compressor Manual Part No 99904145...

Page 17: ...Section 1 Compressor Introduction 15...

Page 38: ......

Page 54: ......

Page 71: ...Parts 69 Electrical Schematic 77441156...

Page 72: ...70 IMT CAS2545 Air Compressor Manual Part No 99904145 Hydraulic Schematic 99904155...