Operation 35

MINIMUM PRESSURE VALVE

The minimum pressure valve is located at the outlet of the coalescer head and serves to

maintain a minimum discharge pressure of 65 PSIG in operation, which is required to assure

adequate compressor lubrication pressure.

OIL FILTER

The compressor oil filter is the full-flow replaceable element type.

COMPRESSOR COOLING SYSTEM

The compressor cooling system consists of a remote mounted oil/air cooler with an electric fan.

The fan is activated through a temperature switch (180°) and latching relay, so it will not turn off

until the compressor is disengaged and the system pressure is fully relieved, or when the engine

is turned off. The thermal valve will divert oil to the oil cooler at 160°F.

ELECTRICAL AND SAFETY CIRCUIT SYSTEM

The unit is supplied with an hourmeter, wire harness and a high temperature shutdown switch.

Compressor shutdown occurs in the event of high compressor temperature (> 250°).

AUTOMATIC BLOW DOWN VALVE

There is one blow down valve in the compressor system. It is located inside the compressor.

The valve will automatically bleed the sump to atmospheric pressure when the compressor is

disengaged. The blow down time interval is typically less than 90 seconds.

CONTROL SYSTEM

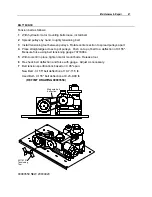

The prime component of the compressor control system is the compressor inlet valve. The

control system is designed to match air supply to air demand and to prevent excessive

discharge pressure when compressor is at idle. Control of air delivery is accomplished by the

inlet valve regulation and modulation as directed by the discharge pressure regulator.

PRESSURE REGULATOR VALVE

This valve, located inside the compressor, is used to set the desired discharge pressure within

the operating pressure range. Turning the regulator screw clockwise increases the working

pressure; a counterclockwise movement of the screw reduces the working pressure. This

system has a maximum operating pressure of 150 psi.