36

IMT CAS3560 Air Compressor Manual Part No. 99903566

NOTE

The operating pressure range for most air tools is between 90 and 125 psi. Operating above

the tools' recommended pressure will decrease the life of the tool. Higher operating pressure

can also over torque nut and bolts fatiguing the fastener and mating parts. Strictly adhere to

tool operating pressures and torque standards set forth by the tool manufacturer and the

specifications of the equipment that work is being performed on.

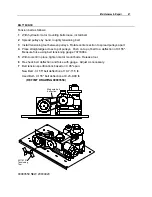

INLET VALVE

The compressor inlet valve is a piston operated disc valve that regulates the inlet opening to

control capacity and serves as a check valve at shutdown.

AIR AFTERCOOLER

The air after-cooler is a second chamber of the oil cooler. Air leaving the compressor enters the

after-cooler. Temperature of the air is reduced to approximately 10-15°F above ambient

temperature. Condensation is directed to the air tank, where it is collected.

CONTROL SYSTEM OPERATION

The following discussion explains the operation of the control system from a condition of “no

load” to a condition of “full capacity” at working pressure. For the working pressure range of

your machine, refer to applicable data in “Specifications”.

The pressure regulator, mounted near the fan/cooler assembly, operates as follows:

1

As the demand for air decreases, the receiver pressure rises. When this pressure exceeds

the set point of the pressure regulator, the regulator opens sending a secondary pressure

signal to the inlet valve. The poppet valve moves towards the valve inlet against the force of

the modulating spring inside the valve. This regulates the opening area of the inlet valve.

2

If the air demand goes to zero, (service valve closed or air dead headed at tool) the inlet

valve will close completely.

3

As the demand for air increases, the secondary pressure signal to the inlet valve is removed

and the inlet valve poppet modulates to full open.