Operation 37

Compressor Operation Test

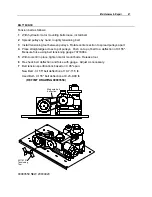

Each compressor is bench tested under load at the factory to ensure proper break-in and

operation. While it is not necessary to follow any break-in procedures, complete the following

checks before putting the unit into service and periodically during use.

1

Before start-up

a) Check the compressor oil level using the sightglass on the unit. If oil is required, use only

IMT's synthetic compressor oil. Always check compressor oil level with the truck cold and

the compressor on level ground.

b) Check the air intake filter indicator (visible at the front of the compressor) for cleanliness

and obstructions. A dirty or obstructed filter may cause reduced air output. The indicator

will be in the red zone when the filter needs attention.

c) Avoid operating the compressor package when the side-to-side or front-to-rear tilt is

greater than 20°.

CAUTION

Prior to compressor start-up, make sure the cover, guards, and access plugs are in place

and secured.

2

With the compressor engaged:

a) Adjust engine speed to ensure that compressor speed does not exceed 8000 RPM

(max.) under load. Crack open air discharge valve until air pressure drops to 140 PSI

and maintains this pressure. Doing so simulates a maximum load condition.

b) If engine speed increase is required, readjust air discharge valve to 140 PSI after speed

has been increased. Repeat until appropriate compressor RPM (NOT engine RPM) is

achieved.

c) Check the compressor RPM using a phototach on the compressor input pulley, located

through the canopy cover.