Maintenance & Repair

43

CAS3560 Maintenance Procedures

Maintenance intervals in the schedule outlined in this manual are based on one hour of

compressor operation equal to about 40 road miles on an engine. Thus, eight hours operation is

equal to 320 road miles, 250 hours is equal to 10,000 road miles, etc.

Only inspection processes can be completed with the compressor covers on. To complete any

maintenance procedures, the covers must be removed.

LIFTING COMPRESSOR

A hole with 5/8-11 UNC threads is provided on the top of the compressor. This threaded hole is

designed to be used with an eyehook or lifting hook to lift the compressor. Lift hooks or

eyehooks with a rating of at least 600 pounds must be provided by the customer.

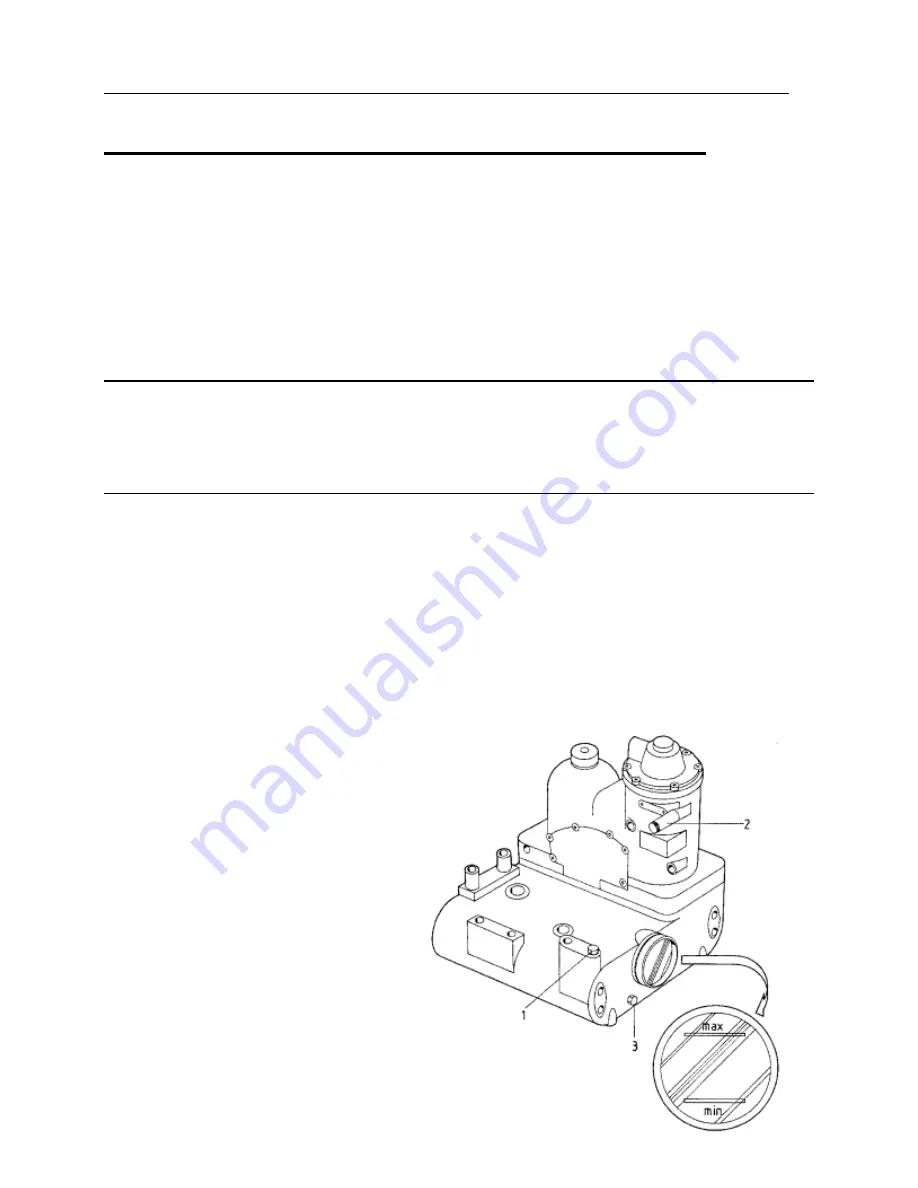

COMPRESSOR OIL SUMP FILL, LEVEL, AND DRAIN

CHECKING COMPRESSOR OIL LEVEL

The proper compressor oil level, when unit is shut down and has had time to settle, is at the

midpoint of the oil sightglass. The truck must be level both side to side and front to back when

checking the oil.

ADDING OIL TO COMPRESSOR

1

Before adding or changing

compressor oil, completely

drain air tank and relieve

pressure by opening pressure

relief valve.

2

Remove filler cap and add new

oil until the upper limit of the oil

level indicator is reached. Oil

can be added at the oil fill tube

(1).

3

Replace filler cap.

4

Close pressure relief valve (2).