3 - 2

99906549 rev 00 (JANUARY-2020)

SECTION 3: INSTALLATION

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

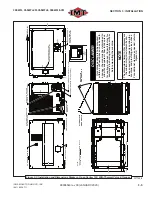

3.3 DETERMINING THE CAS40PL

UNIT MOUNTING LOCATION

When determining the location to mount the

CAS40PL unit, the following criteria must be tak-

en into consideration:

• The mounting surface must be level and able to

accommodate the four (4) mounting bolts and

isolators of the base frame. Refer to

Figure

3-1

or

Figure 3-2

for layout of mounting hole

slots’ locations.

IMPORTANT

Mounting surface must be able to bear the

weight of the machine (255-260 lbs, wet).

• Mount the machine with a minimum of four (4)

mounting locations.

• The location must allow for the machine dimen-

sions, and additional space requirements for

minimum cooling, maintenance and access.

Refer to

Figure 3-3

to determine the additional

minimum space requirement measurements.

• The external gauges/display must be easily

visible to the operator.

It is recommended, for most installations, to

mount the compressor on the driver’s side of the

vehicle. The unit should be situated in such a

manner that the fan (rear) and hydraulic cooler

(front) are not obstructed. Do not place the com-

pressor in any location where it can ingest ex-

haust fumes, dust or debris.

NOTE

When considering external system layout hoses

refer to Section

7.22, Hose Guide

for proper

routing and mounting practices.

3.4 HYDRAULIC

SYSTEM

OVERVIEW

IMPORTANT

IMT

®

highly recommends consulting a hydraulic

supply expert for specifying the correct hydrau-

lic supply components for vehicle-side integra-

tion (including oil reservoir size, hydraulic pres-

sure relief, hose size, etc.) for your application.

IMPORTANT

Contaminated hydraulic

fl

uid allowed to enter

the pump will cause malfunction of the pump

controls. Hydraulic system hoses must be

fl

ushed and cleaned prior to being connected to

the unit.

Refer to

Figure 3-1

or

Figure 3-2

for hydraulic

pump system connections.

Please take into consideration the following:

• The hydraulic

fl

ow and pressure requirements

of the system.

• A continuous hydraulic load is necessary when

compressor is running.

• The duty cycle and ambient operating tempera-

tures.

• Other hydraulic equipment which may share

that same hydraulic supply system (IMT rec-

ommends a dedicated pump and hydraulic

circuit).

WARNING

Follow all applicable safety recommendations

as outlined in Section 1: Safety of this manual.

WARNING

Improperly, or non-connected lines may cause

harm, and will damage the equipment.

The hydraulic hoses must be run to the machine.

Verify that hoses are hooked up properly to en-

sure proper

fl

ow. Also, verify that the hoses are

laid out properly so that no cha

fi

ng or kinking

of the hoses is possible. Refer to

Section 7.22,

Hose Installation Guide

, for assistance with

proper hose layout and connecting functions.

NOTE

The temperature of the hydraulic oil should not

exceed 160°F due to the rating of the IMT- sup-

plied hydraulic motor.

3.4.1 HYDRAULIC SYSTEM

FILTRATION

IMT recommends using a 10 micron oil

fi

lter on

Summary of Contents for CAS40PL

Page 2: ...BLANK PAGE...

Page 81: ...BLANK PAGE...