3 - 6

99906549 rev 00 (JANUARY-2020)

SECTION 3: INSTALLATION

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

the hydraulic oil return line. Flow rating of the

fi

l-

ter must be equal to, or greater than, the maxi-

mum GPM at which the system will be operated.

IMPORTANT

Use only a

fi

lter that is speci

fi

cally intended for

hydraulic systems.

3.4.2 HYDRAULIC OIL RESERVOIR

3.4.2.1 DETERMINING

RESERVOIR

SIZE

In a conventional hydraulic system, minimum

tank size, in gallons, should be equal to the max-

imum GPM

fl

ow rate, times two (x 2).

3.4.2.2 DETERMINING

RESERVOIR SHAPE

The reservoir structure should be tall and narrow

rather than shallow and broad (

Figure 3-4

). A tall,

narrow tank is recommended because:

1. The oil level is well above suction line open-

ing, avoiding the possibility of drawing air into

the pump due to a vortex or “whirlpool” e

ff

ect

within the tank during operation

fl

ow.

2. Allows for better oil level tolerance level of

the system if vehicle operates at an unusual

(slightly o

ff

level) vehicle angle.

3. To keep return

fl

ow well below the surface so

it does not break the surface and cause aer-

ation (cavitation) of the oil.

3.4.2.3 MANDATORY

RESERVOIR

FEATURES

• The reservoir should incorporate the following

design features:

• In terms of location of the reservoir tank within

the hydraulic system, note that the hydraulic

pump’s inlet line (suction line out from the res-

ervoir to the pump) should be located near the

bottom of the tank, well below the oil level. The

suction line should protrude a minimum of two

(2”) inches into the reservoir to keep it away

from potential contaminant surface buildup.

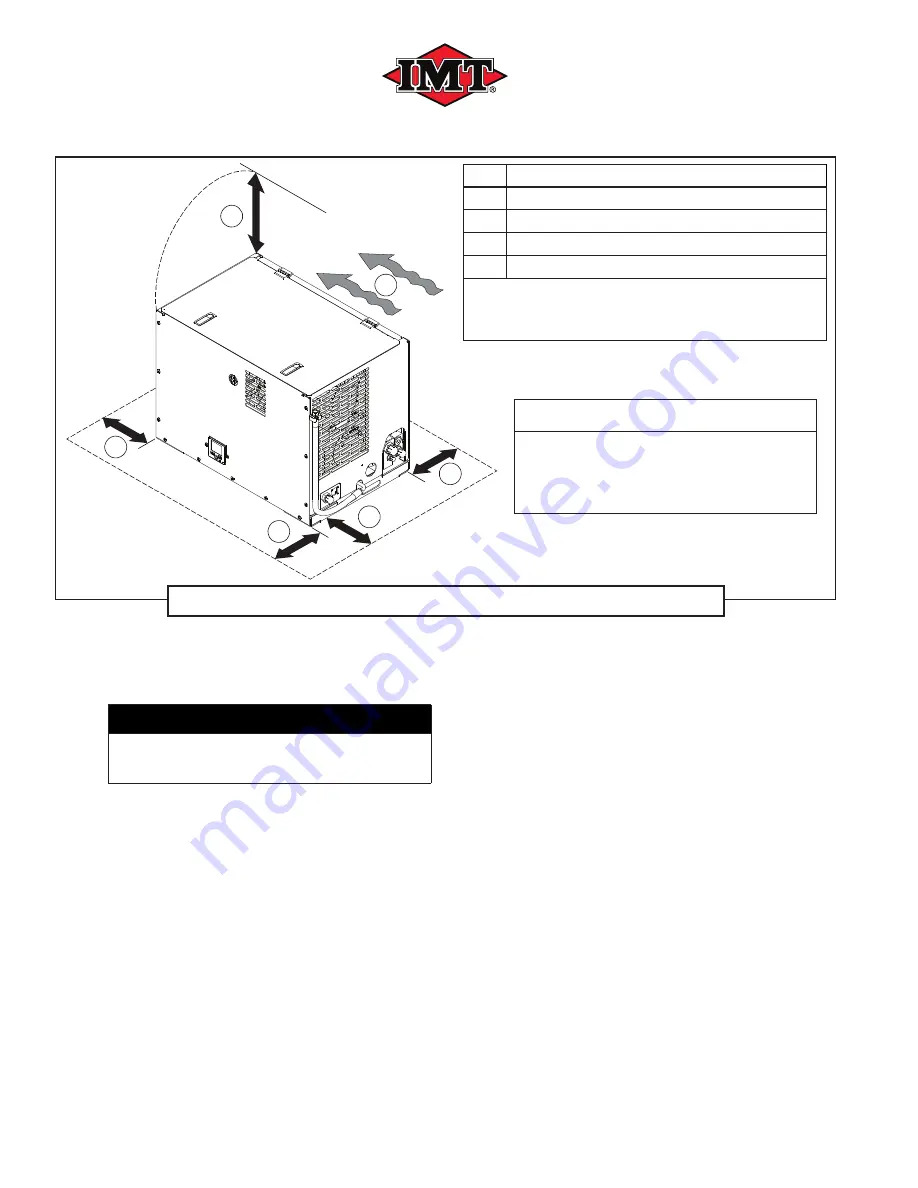

A

B

B

C

C

D

Figure 3-6: Minimum Clearnace Distances Needed for Machine Cooling and Access

KEY

DESCRIPTION

A

ROOF ACCESS PANEL CLEARANCE: 24”

B

MACHINE LATERAL CLEARANCES: 10”

C

MACHINE FRONT/REAR CLEARANCES: 10”

D

COOLING AIR FLOW DIRECTION

NOTE:

The dimensions listed above are the minimum required clearance

distances needed for properly cooling the machine. Additinal clearance

room may be desired for easier acess for control and/or maintenance

functions.

IMPORTANT

Additional allotted dimensions/surroundings

space of package must allow for continu-

ous circulation of air around and through

the machine for cooling purposes. DO NOT

install in an enclosed area.

Summary of Contents for CAS40PL

Page 2: ...BLANK PAGE...

Page 81: ...BLANK PAGE...