99906549 rev 00 (JANUARY-2020)

3 - 9

SECTION 3: INSTALLATION

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

nection port panel end of the unit. This system is

o

ff

ered with 12V DC circuits.

3.5.6 HYDRAULIC SUPPLY CIRCUIT

Refer to the proper hydraulic

fl

ow schematic

drawing (

Section 7.20

or

7.21

) that mathces the

machine model build. It is recommended that the

compressor unit possesses a separate pump/

fl

ow/return hydraulic circuit to other hydrau-

lic equipment. This is to prevent the possibility

of pressure/

fl

ow drops that may occur if other

hydraulically-powered equipment is activated

during compressor operation, which may in turn,

cause the compressor to stall out. Alternatively,

use of a diverter valve will permit hydraulics to

power di

ff

erent equipment selectively.

3.5.7 ROUTING

Refer to

Figure 3-1

or

Figure 3-2

, and the elec-

trical and wiring diagrams (

Sections 7.18

and

7.19

). Ensure that all supply hoses and electrical

wiring are correctly speci

fi

ed, adequately sup-

ported, and do not touch or rest on any sharp

edges. Wiring should be protected with split loom

to prevent corrosion, and consequently, loss due

to down time.

3.5.8 HYDRAULIC SYSTEM

REQUIREMENTS

Refer to

Sections 7.20

and

7.21

for hydraulic

system schematic layouts and components. The

following requirements should be taken into con-

sideration before installing the hydraulic system:

• The hydraulic

fl

ow and pressure requirements

of the air compressor.

• A continuous hydraulic load is necessary when

the compressor is running.

• The duty cycle and ambient operating tempera-

tures.

• Other hydraulic equipment which may share

the same hydraulic supply system (IMT rec-

ommends a dedicated pump and hydraulic

circuit).

3.6 CONNECTING

THE

HYDRAULIC SUPPLY AND

RETURN

Refer to

Figure 3-1

or

Figure 3-2

for hydraulic

supply and return hose location connections and

layout routing. Use correctly rated hoses (3000

PSI minimum) to securely connect both supply

(¾” J.I.C. 37° male) and return connectors (1”

J.I.C. 37° male).

NOTE

IMT recommends:

• SUPPLY HOSE: 3/4” J.I.C., 3000 PSI

• RETURN HOSE: 1” J.I.C., 500 PSI

• CASE DRAIN: 3/8” J.I.C., 500 PSI (load sense

1/4" JIC 3000 PSI; closed-center only)

3.7 CONNECTING

THE

AIR

SUPPLY

Refer to

Figure 3-1

or

Figure 3-2

for service

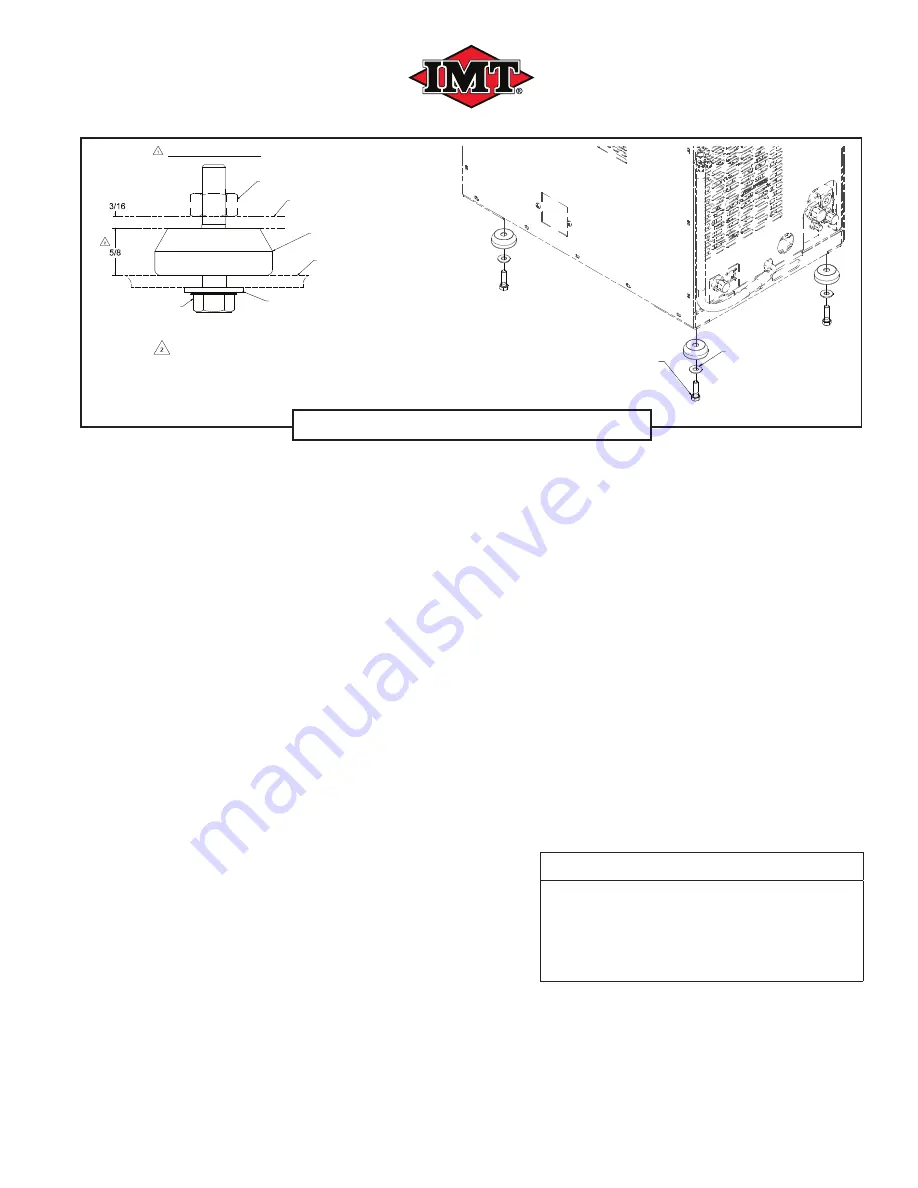

NOTES:

1. APPLY THREAD LOCKER TO HEX BOLTS BEFORE INSTALLATION

2. TIGHTEN BOLT UNTIL ISOLATOR IS COMPRESSED FROM NORMAL

EIGHT OF 1" TO FINAL HEIGHT OF 5/8"

Ø.50 FLAT (4X).

WASHER SUPPLIED

BY CUSTOMER

1/2-13 GR 8 HEX HEAD

CAPSCREW (4X)

LENGTH TO BE

DETERMINED AND

SUPPLIED BY

CUSTOMER

INSTALLED CONDITION

BUMPER

HEX HEAD

CAPSCREW

EXISTING WELDNUT

COMPRESSOR

FRAME

MOUNTING SURFACE

FLAT WASHER /

SEALING WASHER

Figure 3-5: Installation - Machine Isolator Mounting

280378_r2

Summary of Contents for CAS40PL

Page 2: ...BLANK PAGE...

Page 81: ...BLANK PAGE...