4 - 2

99906549 rev 00 (JANUARY-2020)

SECTION 4: OPERATION

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

service demands and receiver tank pressure.

6. Move the PTO ON/ OFF switch to the OFF

position.

NOTE

Ensure that the service valve is closed and

compressor has stopped.

4.3.1 ROUTINE START-UP PROCEDURE

IMPORTANT

If start-up and shut-down procedures are not

followed, damage to the system and its compo-

nents may occur.

Refer to

Figure 5-2

in

Section 5.4.3.1

for unit

check locations, and

Figure 4-1

for instrumenta-

tion.

1. Ensure all service outlets are closed.

2. Ensure that the PTO ON/OFF switch is in the

ON position (fully engaged).

3. Apply hydraulic power.

4. Check for hydraulic supply or return leaks

and correct if required.

5. Allow air pressure to build up in the receiver

tank.

6. Move the PTO ON/ OFF switch to the OFF

position.

NOTE

Ensure that the service valve is closed and

compressor has stopped.

4.3.2 ROUTINE SHUTDOWN PROCEDURE

(FIRST AND ROUTINE)

IMPORTANT

If start-up and shut-down procedures are not

followed, damage to the system and its compo-

nents may occur.

IMPORTANT

Do not stop the engine suddenly! Stop the

engine after approximately

fi

ve (5) minutes of

unloaded idling.

1. Close service valve.

2. Allow compressor system to unload and cool

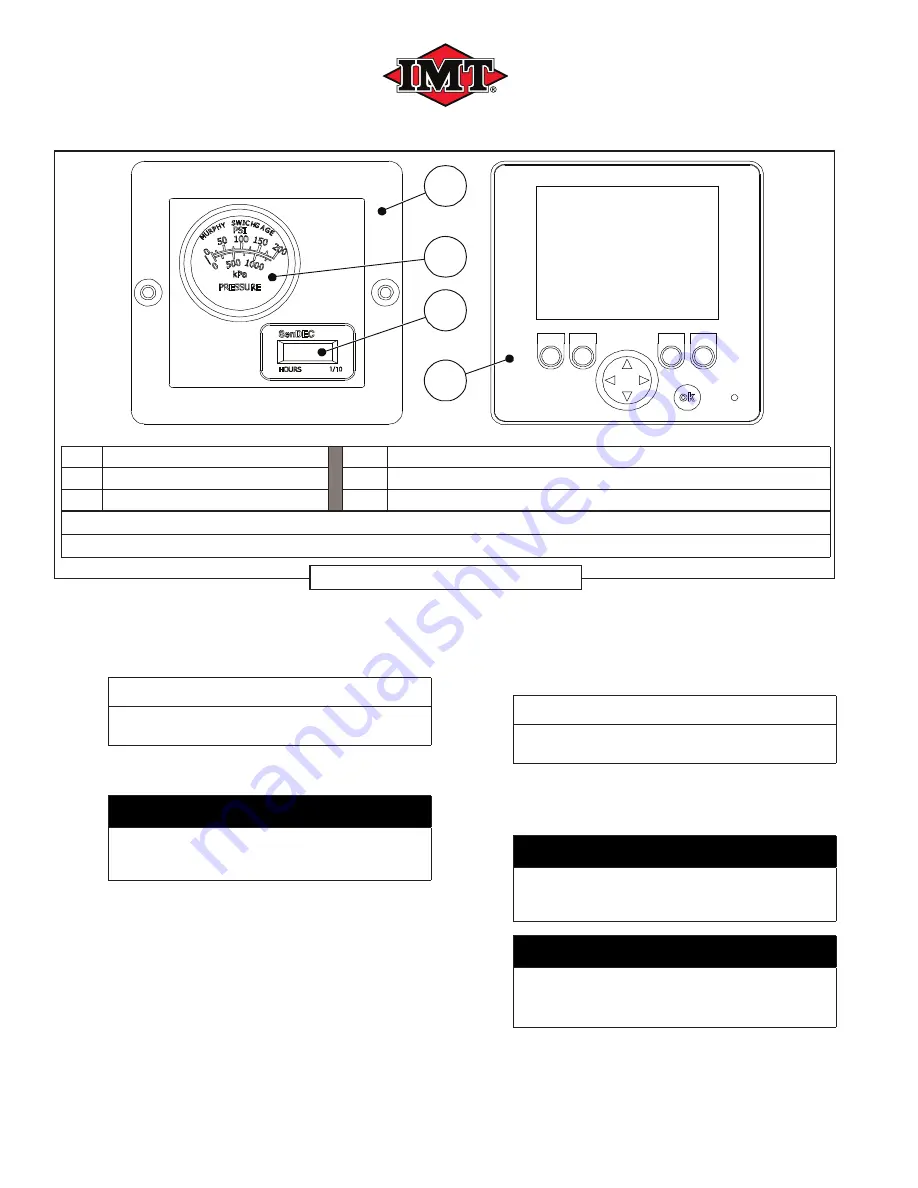

B

C

A

D

KEY

DESCRIPTION

KEY

DESCRIPTION

A

PNEUMATIC GAUGE PANEL

C

HOUR METER

B

PRESSURE GAUGE

D

DIGITAL DISPLAY CONTROLLER

I

I

Refer to

Figure 4-2

for digital controller identi

fi

cation and navigation.

Note that machine control panel option will be either

A

or

D

from the table above, depending upon order speci

fi

cation.

Figure 4-1: Instrumentation

Summary of Contents for CAS40PL

Page 2: ...BLANK PAGE...

Page 81: ...BLANK PAGE...