5 - 4

99906549 rev 00 (JANUARY-2020)

SECTION 5: MAINTENANCE

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

TABLE 5A: ROUTINE MAINTENANCE SCHEDULE

W

ARNING

Before performing maintenance:

Shut down machine, relieve all system pressure and lock out all power

, as per the Safety Section

of this manual. If machine is hot, allow package

to cool before removing any panel.

NOTE THA

T THE SYSTEM CAN BE ST

ARTED

REMOTEL

Y

:

Always clearly tag the start-up instrumentation against accidental system start-ups during main-

tenance.

MAINTENANCE

INTER

V

ALS

Hourly or Calendar Period - whichever

comes

fi

rst

TABLE 5B: ROUTINE REPLACEMENT P

ARTS KITS

*

KEY

#

DESCRIPTION

ORDER #

QTY

1

Kit, Compressor Service - Initial 50 Hours

II

71417219

1

2

Kit, Compressor Lifetime W

arranty Service - 500 Hours

II

71417220

1

*

If working in dusty or dirty conditions, reduce the recommended time intervals between

servicing by half for engine and compressor oil replacement, and engine and compressor

fi

lter

servicing.

II

For detailed kit content descriptions refer to

Section 7, T

able 7A

. Also Refer to

Section 7,

Table 7A

for full replacement parts listing, including separate components, non-routine items,

and options.

PLEASE NOTE: WHEN ORDERING P

ARTS, INDICA

TE MACHINE SERIAL

NUMBER.

Daily Maintenance

Weekly Maintenance

Every 500 Hours or

Annually

KEY

TASK DESCRIPTION

ACTION T

O

T

AKE

7

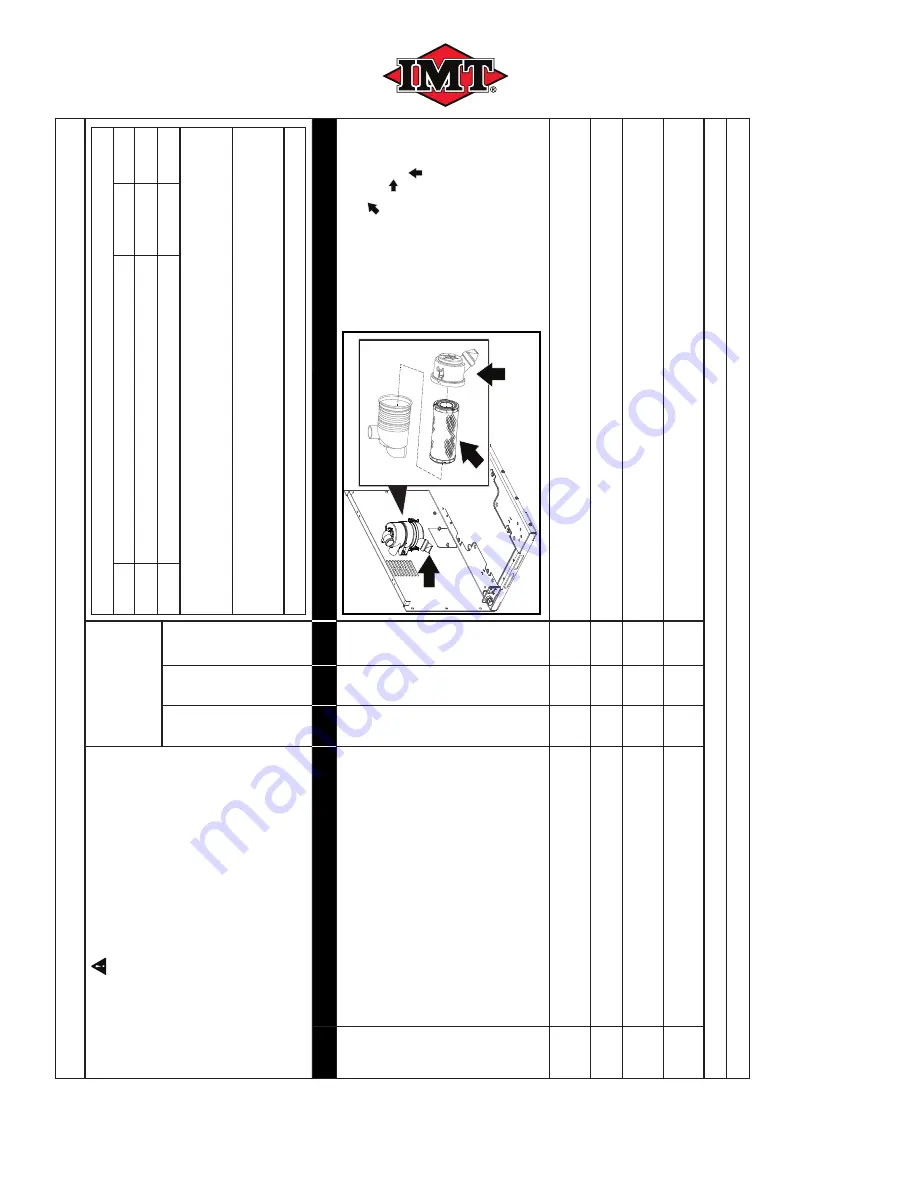

Remove, inspect, and clear air intake

fi

lter

if

necessary

I

.

██

REFERENCE:

•

Air Filter Element [

]

• Dust Evacuator V

alve [

]

•

Air Filter Housing Cover [

]

PROCEDURE:

Consult

Section 5.4.4

for procedure

on how to inspect and/or change the

air intake

fi

lter

.

8

Inspect and clean the compressor valves.

II

Consult the IMT

Service Department for maintenance procedure for the compressor

valves.

9

Change the compressor crankcase oil.

█

Consult

Section 5.4.3

for procedure on changing the crankcase oil.

10

Check the hoses for damage or other signs of

deterioration.

█

Consult

Sections 7.13

through

7.16

for assistance with hose replacement.

11

Check the wiring for damage or deterioration and

ensure that connections are secure.

█

Refer to

Sections 7.18

and

7.19

(Electrical System Wiring Diagram) for wire system route

connections.

I

Air

fi

lters inspection performed weekly (change if needed); air

fi

lters change interval is yearly

, or sooner depending upon inspection.

II

V

alves should be removed from the cylinder heads every 500 hours or annually (whichever comes

fi

rst) and examined for cleanliness and carbon formation (build-up).

Summary of Contents for CAS40PL

Page 2: ...BLANK PAGE...

Page 81: ...BLANK PAGE...