99906549 rev 00 (JANUARY-2020)

5 - 5

SECTION 5: MAINTENANCE

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

5.4 PARTS

REPLACEMENT

AND

ADJUSTMENT PROCEDURES

WARNING

Follow all applicable safety recommendations

as outlined in Section 1: Safety of this manual.

WARNING

Before performing maintenance:

Shut down machine, relieve all system pressure

and lock out all power, as per the Safety Section

of this manual. If machine is hot, allow package

to cool before removing any panel.

NOTE THAT THE SYSTEM CAN BE STARTED

REMOTELY:

Always clearly tag the start-up instrumentation

against accidental system start-ups during

maintenance.

WARNING

DO NOT use tools, hoses, or equipment that

have maximum ratings below that of this com-

pressor.

WARNING

DO NOT use

fl

ammable solvents or cleaners for

cleaning the compressor or its parts.

NOTE

Wear appropriate protective (eye and hear-

ing protection) equipment and clothing when

operating or maintaining this equipment. DO

NOT wear jewelry, loose clothing; and long hair

should be restrained with headband or safety

hat.

NOTE

Keep the equipment clean when performing

maintenance or service actions. Cover open-

ings to prevent contamination.

NOTE

When using compressed air to clean the com-

ponents, the nozzle pressure should not exceed

15 PSIG.

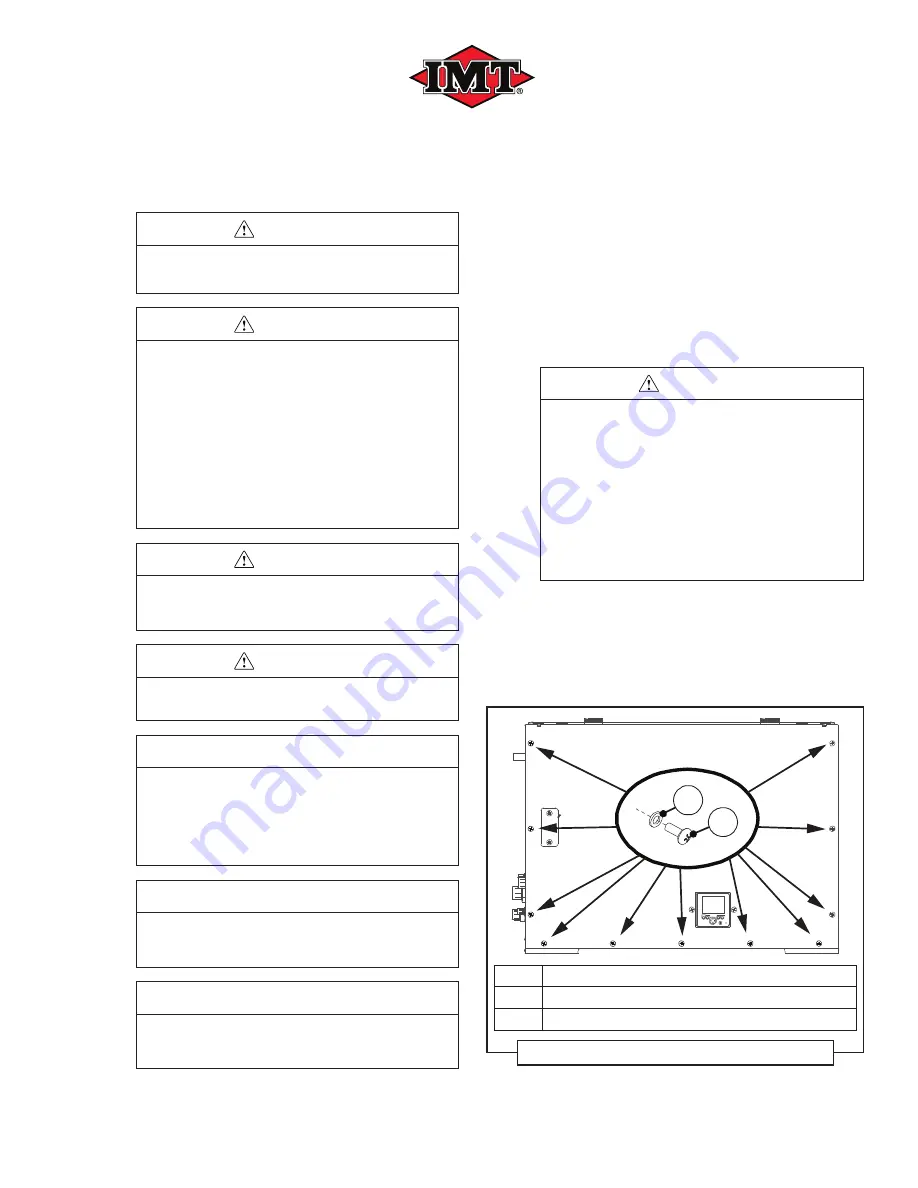

5.4.1 REMOVING PANELS FOR MA-

CHINE MAINTENANCE ACCESS

Although most of the routine maintenance proce-

dures can be accessed from either outside of the

compressor package or via the top roof access

panel, some procedures will require the tempo-

rary removal of one or both side panels in order to

freely service the maintenance item. Consult

Fig-

ure 5-1

and the proper panel removal sub-sec-

tion listed below to remove the desired panel.

WARNING

Before performing maintenance:

Shut down machine, relieve all system pressure

and lock out all power, as per the Safety Section

of this manual. If machine is hot, allow package

to cool before removing any panel.

NOTE THAT THE SYSTEM CAN BE STARTED

REMOTELY:

Always clearly tag the start-up instrumentation

against accidental system start-ups during

maintenance.

5.4.1.1 REMOVING LONG-SIDE PANELS

FOR MAINTENANCE ACCESS

Consult

Figure 5-1

and the following procedures

to remove a side panel for maintenance access.

A

B

KEY

DESCRIPTION

A

TRUSS SCREW, 1/4-20 X 3/4” (X 11 each/side panel)

B

WASHER, NYLON FLAT 1/4” (X 11 each/side panel)

Figure 5-1: Panel Removal

Summary of Contents for CAS40PL

Page 2: ...BLANK PAGE...

Page 81: ...BLANK PAGE...