99906549 rev 00 (JANUARY-2020)

5 - 13

SECTION 5: MAINTENANCE

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

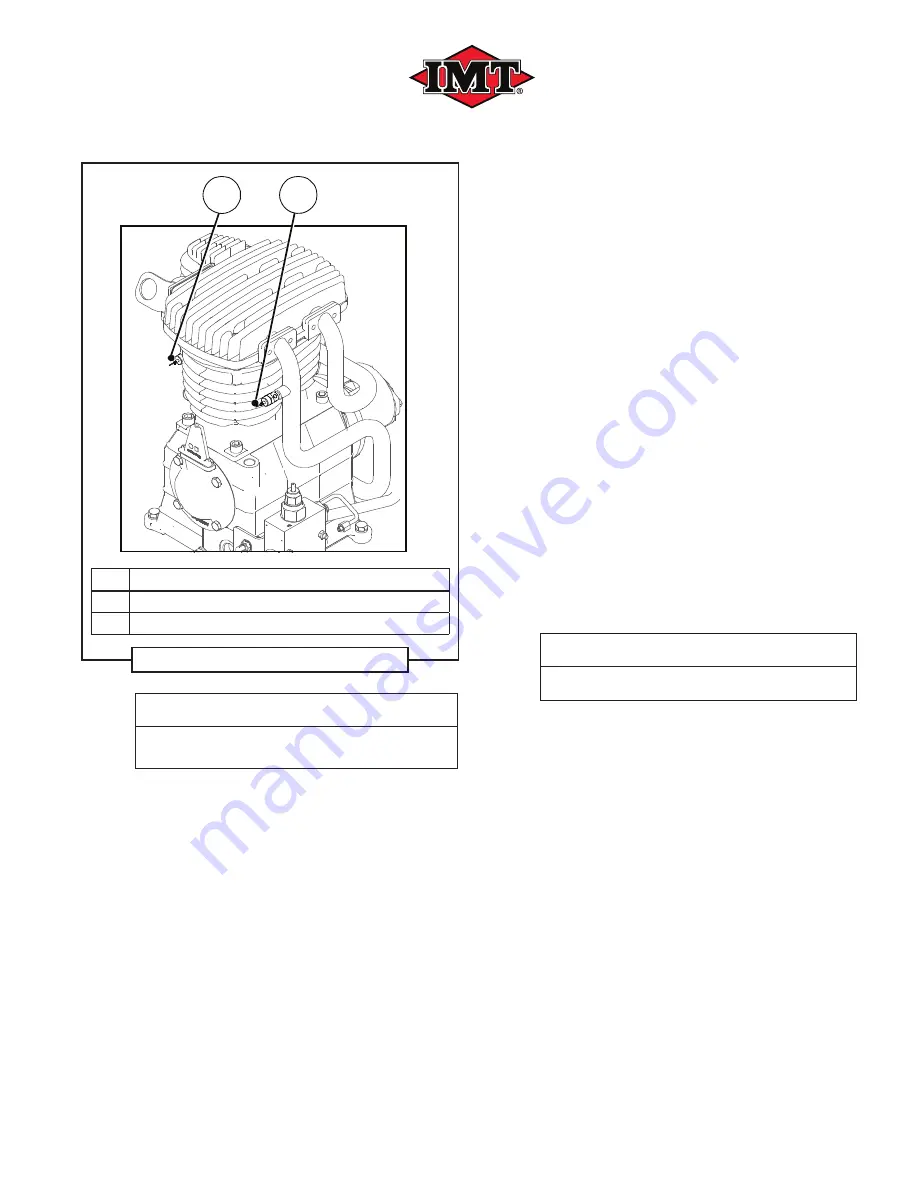

B

A

KEY

DESCRIPTION

A

RELIEF VALVE - 200 PSIG (15 BAR; 217 PSIG)

B

RELIEF VALVE - 65 PSIG (4.5 BAR)

Figure 5-8: Compressor Relief Valves

NOTE

If valves vent excessively more than once,

replace valve.

5.7 LONG TERM STORAGE

Parts can wear out over time, regardless of the

degree of usage. If storing the CAS40PL unit for

long periods of time, prepare the unit by doing the

following:

• De-pressurize the air tank and open the drain

valve on the tank.

• Cover with a waterproof secured tarp or plastic

sheet to prevent the accumulation of dust, but

leave the bottom open for air circulation. The

covering should allow for easy removal for

in-storage maintenance.

• Whenever possible, store in a sheltered area to

minimize exposure to the elements.

• While in storage, every two (2) to three (3)

months rotate the compressor and motor by

hand to prevent

fl

at spots on the bearings that

will lead to premature failure.

At the end of the storage period, follow the un-

packing, general, and start-up procedures. If the

unit has been stored for more than eighteen (18)

months, the IMT

®

Service Department should be

consulted before restarting the compressor.

NOTE

IMT does not recommend outside storage.

Summary of Contents for CAS40PL

Page 2: ...BLANK PAGE...

Page 81: ...BLANK PAGE...