99906549 rev 00 (JANUARY-2020)

3 - 7

SECTION 3: INSTALLATION

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

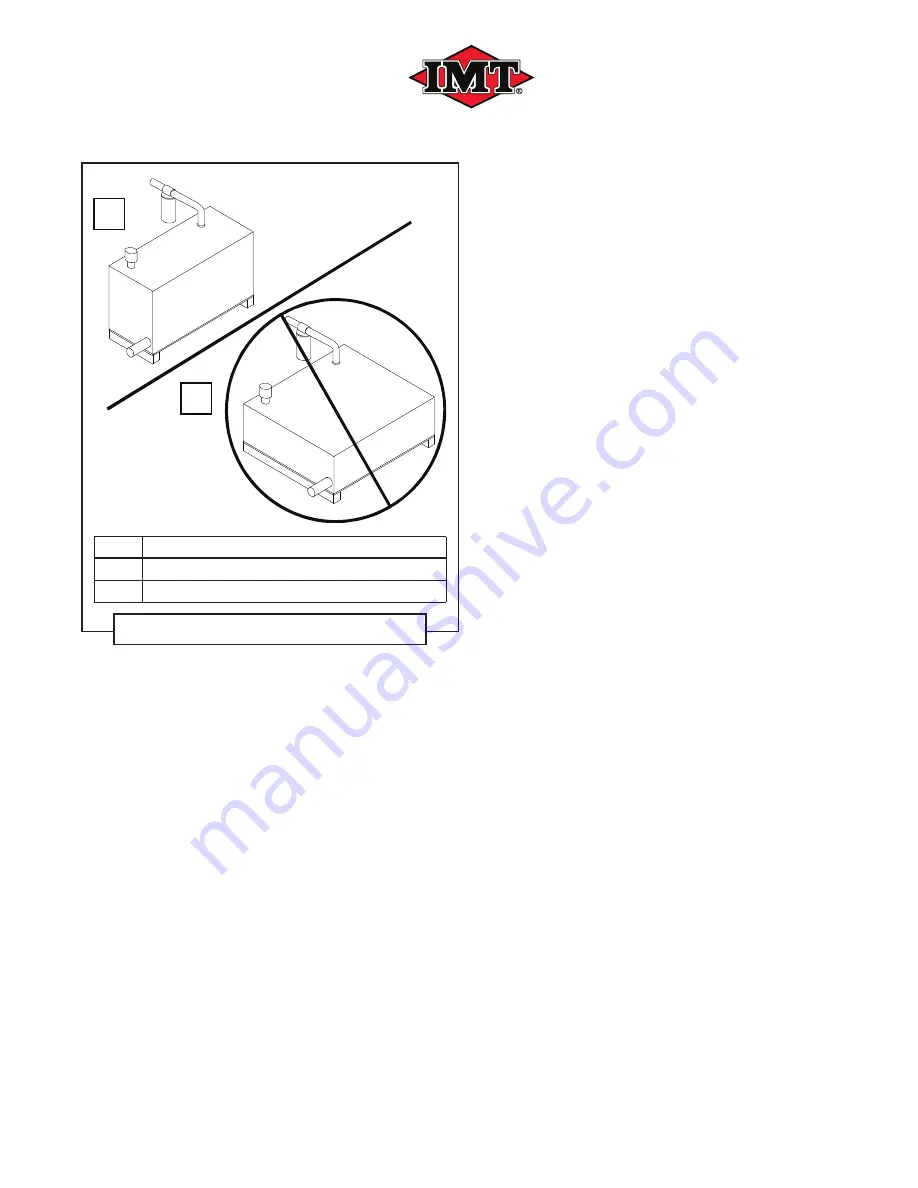

A

B

KEY

DESCRIPTION

A

PREFERRED SHAPE:

TALL AND NARROW

B

SHAPE TO AVOID:

BROAD AND SHALLOW

Figure 3-4: Reservoir Design Shape

• A ba

ffl

e or ba

ffl

es should be included to pre-

vent sloshing, or centrifugal motion of the oil;

the goal is to break up direct

fl

ow of the oil

from the return point to the suction point. This

allows for the cooling action contact with the

tanks’ inner surfaces, and promote separation

of any air or contaminants that interact with

the

fl

owing oil.

• An ideal ba

ffl

e design would position several

(but not too many) ba

ffl

es to promote an ‘S’

shape

fl

ow within the reservoir, as viewed

from above. The area of the end gaps should

be at least twice the area of the suction line

diameter.

• A drain port with plug, situated at the lowest

point of the reservoir, is needed to assure

complete draining. It should be installed using

an adapter or housing which does not pro-

trude above the inner surface of the

fl

oor of

the tank. It should be visible and accessible

for removal, with su

ffi

cient space available for

catching the waste oil.

• If the return line entrance to the tank is located

near the top, it should be extended downward

within the tank to minimize foaming and aer-

ation of the circulating oil. This extends oil in-

tegrity, which in turn helps to maintain system

performance and reliability.

• An in-line

fi

lter on the return line is needed to

protect the system against contaminants be-

ing introduced into the oil. The

fi

lter should be

mounted externally from the reservoir in a lo-

cation that allows for easy of service access.

• A breather and

fi

ll cap is needed at the oil

fi

ll

port, which needs to be located above the

system oil level. The breather cap acts to both

fi

lter air that is drawn into the reservoir as the

oil level diminishes, and bleeds air out as the

level is regained. This maintains constant at-

mospheric pressure in the air volume within

the reservoir.

• A sight-glass provides a direct visual indication

of the oil level without having to open, or oth-

erwise access, the reservoir.

3.4.2.4 RECOMMENDED

RESERVOIR

OPTIONS

Although not essential for an adequately func-

tioning reservoir, the following components will

contribute to maximize the hydraulic system’s ef-

fi

ciency and maintain a quality operational level.

• Magnetic drain plug: Attracts and concentrates

ferrous contaminants at the drain plug source

for easier accessibility and removal when

cleaning tank interior.

• A temperature gauge: Located in approxima-

tion to, or built in to, the sight glass assembly

allows for temperature reading at a glance.

• Filler port strainer: Prevents large contaminant

particles from blending with system oil when

adding new oil.

• Return line di

ff

user (splash) plate reduces ve-

locity of oil

fl

ow before return oil stream merg-

es with the main reservoir oil volume.

• A reservoir heater: For those systems that are

exposed to cold climate ambients, having the

ability to preheat the hydraulic oil prior to start

up will make for easier startups, and reduce

the strain of warming up the system under ad-

Summary of Contents for CAS40PL

Page 2: ...BLANK PAGE...

Page 81: ...BLANK PAGE...