99906549 rev 00 (JANUARY-2020)

5 - 9

SECTION 5: MAINTENANCE

IOWA MOLD TOOLING CO., INC.

(641) 923-3711

CAS40PL, CAS40PL-CW, CAS40PLE, CAS40PLE-CW

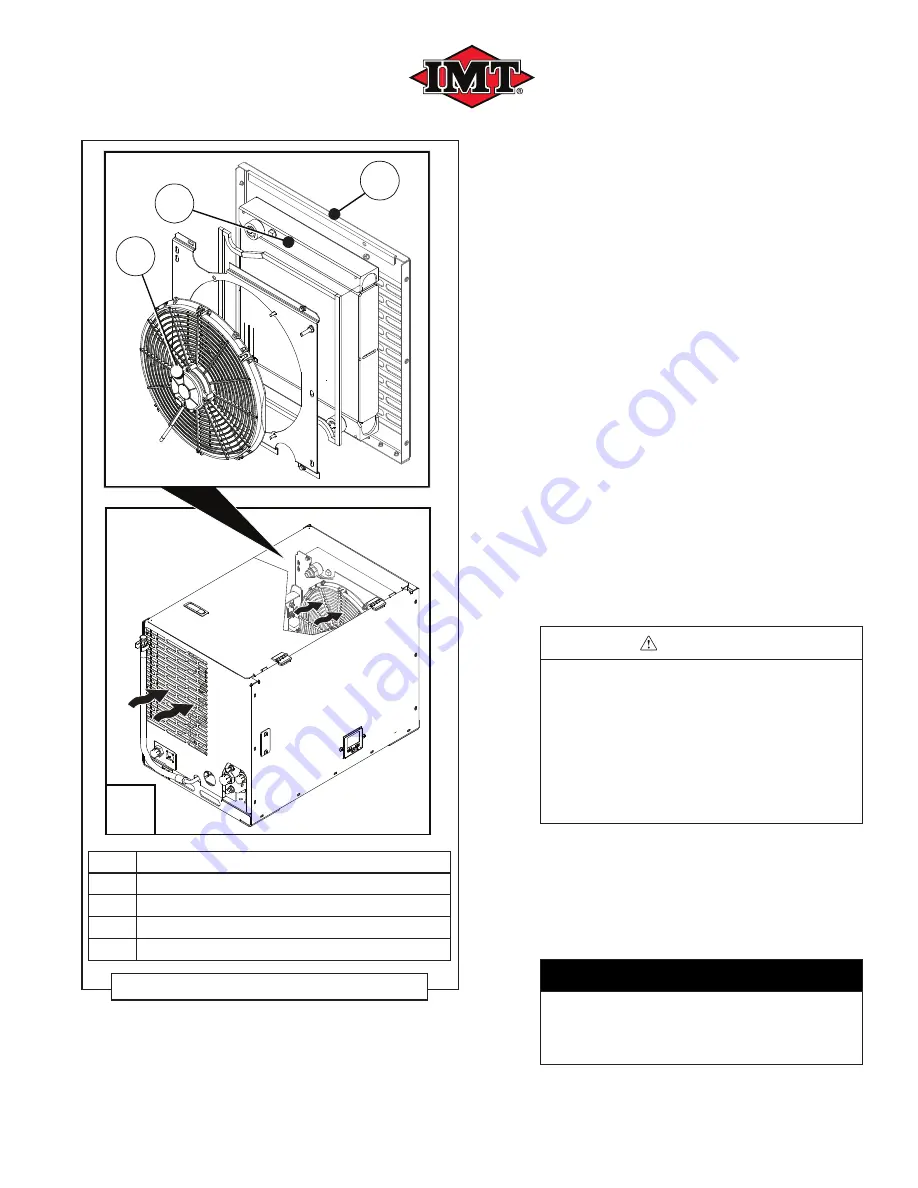

C

B

A

D

KEY

DESCRIPTION

A

COOLER FAN & MOTOR ASSEMBLY

B

OIL COOLER

C

COOLER (CANOPY) PANEL

D

DIRECTION OF COOLING AIR FLOW

Figure 5-4: Typical Cooler Assembly

Should the core become clogged, you can use

low pressure compressed air to blow through the

fi

ns from the inside of the canopy to clean it out.

You may need to remove the fan from the shroud

in order to reach parts of the core.

DO NOT

use

high pressure air or a pressure washer.

If the cooler has become internally clogged, it

may need to be

fl

ushed or replaced. Consult the

IMT

®

Service Department.

5.4.6 COUPLING ALIGNMENT

There is no need to adjust the compressor unit/

hydraulic motor alignment; Alignment is achieved

via the motor-to-unit adapter. In the case where

the drive coupling element needs to be serviced

(refer to

Section 5.4.7

), alignment is automatical-

ly achieved by securing the motor to the unit via

the motor adapter.

However, in the case where the coupling ele-

ment needed to be replaced, or if the alignment

is such that there is excessive machine vibration,

etc., there is a hub alignment check that should

be performed once that maintenance has been

accomplished. Refer to

Section 5.4.7.3

for drive

coupling hub alignment check procedure.

5.4.7 REPLACING THE DRIVE

COUPLING

WARNING

Before performing maintenance:

Shut down machine, relieve all system pressure

and lock out all power, as per the Safety Section

of this manual.

NOTE THAT THE SYSTEM CAN BE STARTED

REMOTELY:

Always clearly tag the start-up instrumentation

against accidental system start-ups during

maintenance.

With proper care of the machine, the drive cou-

pling should normally last inde

fi

nitely. However,

it may become worn or the element may rupture

and need to be replaced. To replace the drive cou-

pling element, order replacement

no. 71417229

,

and follow the procedure below.

IMPORTANT

It is important to remember that the drive cou-

pling contains wear elements that will eventual-

ly fail. Operator must ensure that the assembly

is enclosed to avoid injury in case of a failure.

Summary of Contents for CAS40PL

Page 2: ...BLANK PAGE...

Page 81: ...BLANK PAGE...