28

CAS440HT Air Compressor Manual Part # 99900838

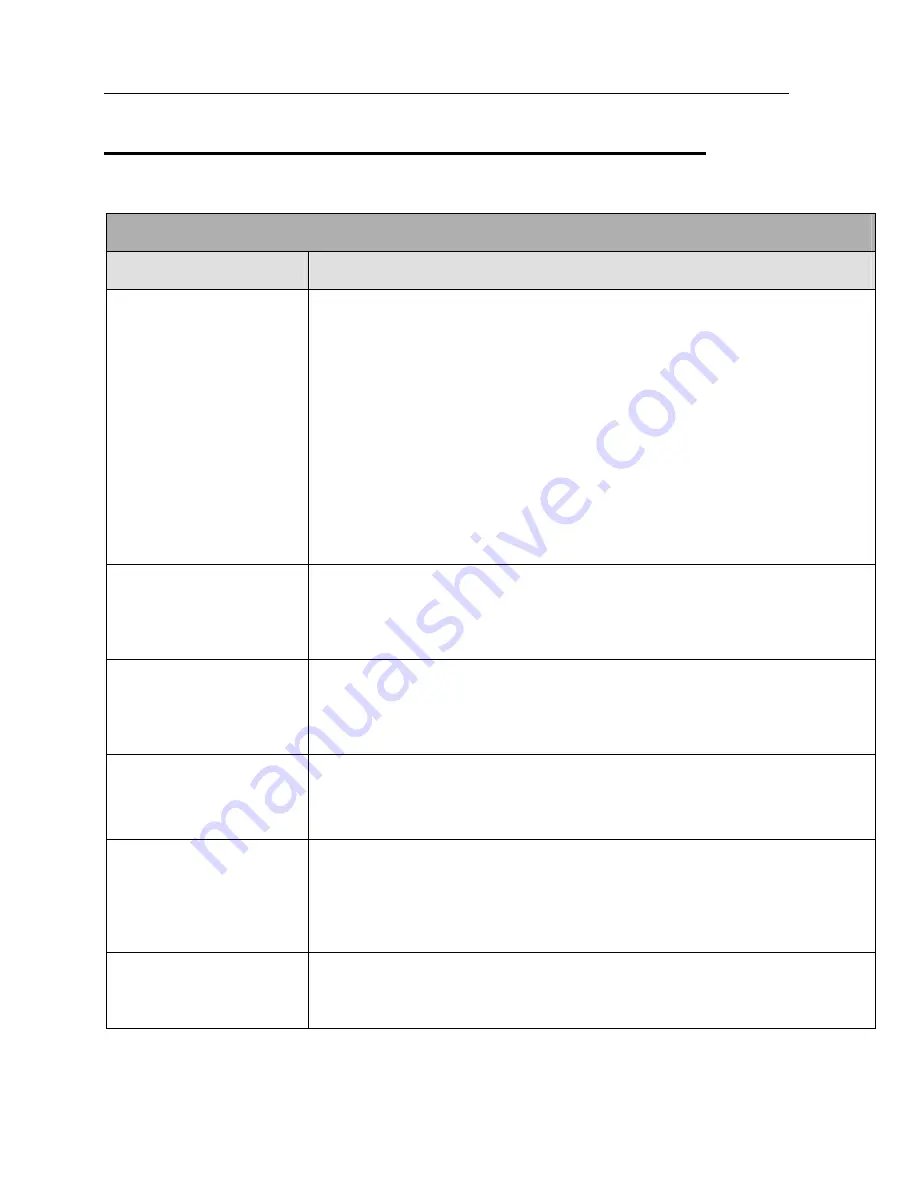

Troubleshooting Guide

Compressor Troubleshooting Guide

Symptom

Probable Cause

Air compressor slows

down as air pressure

increases and the engine

RPM remains the same,

or increases slightly.

1

Relief valve bypassing oil. Adjust relief valve. Turn clockwise to

increase bypass pressure. If this does not correct the problem, return

the relief valve to the original position. Proceed with step #2.

2

Hydraulic pump failure. Disconnect the pressure hoses at the motor

inlet swivel. Cap the hose. Plug the swivel. If the system does not have

a pressure gauge, install one at the end of the hose for testing purposes.

Engage the PTO and release the clutch slowly. Hydraulic oil pressure

should reach 2300 - 2500 PSI before the relief valve opens.

3

Hydraulic motor or valve failure. Disconnect the pressure hose from the

pump at the gauge swivel. Connect the pressure hose from the pump to

the motor inlet swivel. Shut control valve. engage the PTO. Start the

compressor. If this does not correct the problem, replace the motor. If

this does correct the problem, replace the valve.

Motor does not turn when

hydraulic valve is closed.

Oil does not reach 2300 -

2500 psi.

1

Compressor is locked up. Disconnect the drive system and try to turn

the compressor by hand. If it cannot be turned, repair the compressor.

2

Hydraulic motor failure. Replace the motor if the compressor is

operational.

Motor does not turn when

the hydraulic system is

activated. Relief valve

reached 2300 - 2500 psi.

1

Hydraulic motor is beginning to fail. Replace the hydraulic motor before

it damages the rest of the system.

Excessive noise in

hydraulic pump. Pump

gets very hot.

1

Restrictions in oil hoses and fittings. Check and correct any restrictions.

2

Oil tank vent plugged. Check and clean oil tank vent.

3

Hydraulic oil breakdown. Drain and replace.

Hydraulic system

damages pumps. Oil tank

overflows.

1

Tank too full to allow for expansion. Drain excess oil.

2

Oil tank vent plugged. Check and clean.

NOTE: If your truck has two tanks, the return hose from the top tank to the

lower tank may be restricted.

Oil is cold. Compressor is

started cold and fails to

continue to operate.

1

Compressor started too quickly. Insufficient warm-up causes pump

failure. Replace pump, start compressor, and allow sufficient warm-up

time.