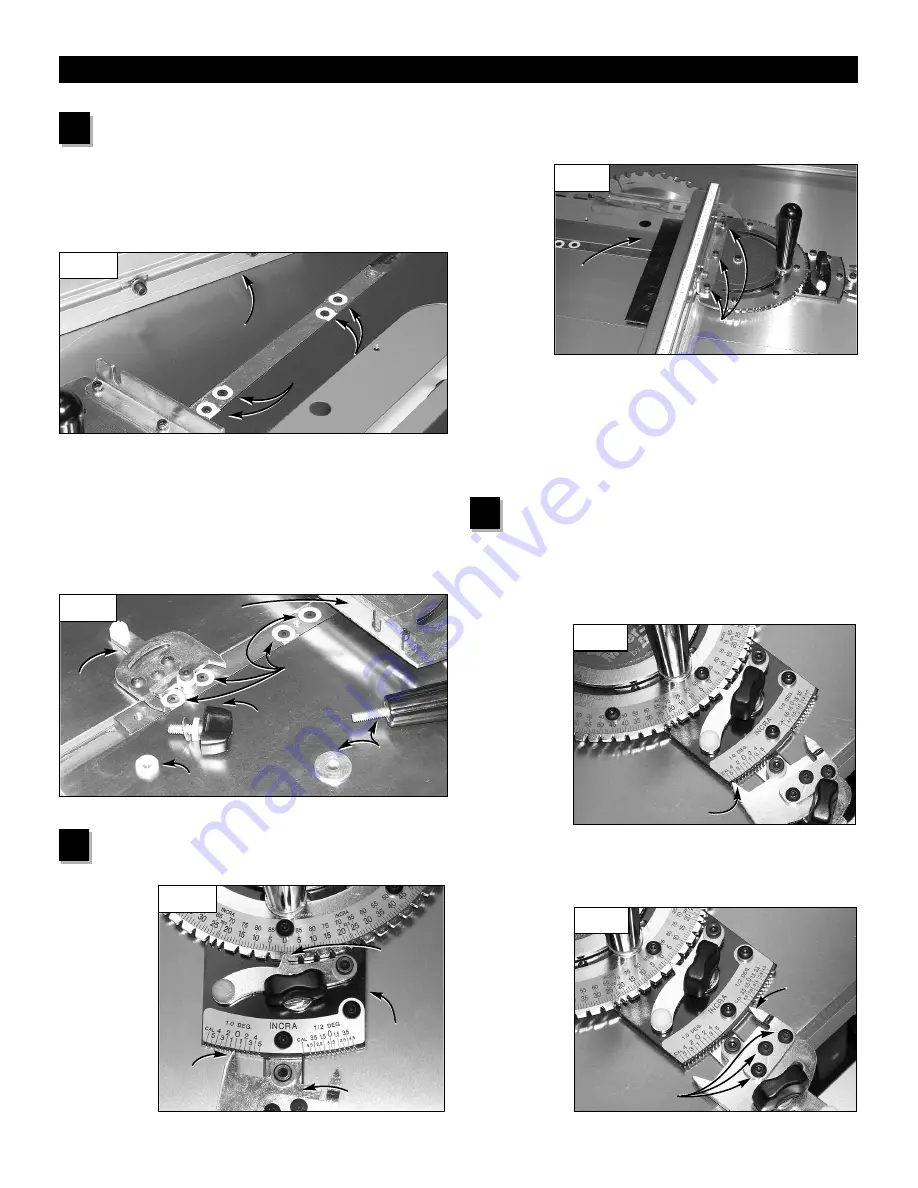

Now pivot the rear actuator to engage the right-hand tooth with

the notch marked "CAL" on the rear scale, Fig. 9. If adjusted

properly, it will pivot perfectly into the notch. To adjust, loosen the

(3) socket head

screws that

secure the tooth

and fine-tune

the position to

align with the

"CAL" notch.

Pivot back and

forth between

the two "CAL"

notches to

verify the

calibration.

Adjust Fence Mounting Bracket 90° to Saw Blade

Loosen the large clamping knob and make sure that the

rear actuator left-hand tooth is engaged firmly with the 0°

notch on the

1

⁄

2

° adjustment plate. Engage the front

actuator tooth

with the 0°

notch located

on the

protractor

head, Fig. 6.

Tighten the

front actuator

thumbscrew

then tighten

the large

clamping knob.

Calibrating the 1/2° Indexing Tooth

The

1

⁄

2

° indexing tooth located on the rear actuator is

factory calibrated and should require no further

adjustment. Follow the instructions below should you wish to

check the calibration or re-calibrate.

Loosen the large clamping knob and the rear actuator

thumbscrew.

Engage the

left-hand tooth

of the rear

actuator firmly

with the notch

marked "CAL"

on the rear

scale and hold

while you

tighten the large

clamping knob,

Fig. 8.

Using the supplied

5

⁄

32

" hex key, loosen the (3) socket head

screws that secure the fence mounting bracket to the protractor

head. Unplug your table saw, then use a reliable machinist

square to set

the fence at

90° to the

saw blade,

Fig. 7.

Tighten the

(3) socket

head screws.

3

Adjust the Miter Bar

Adjust the miter bar at each of the (8) expansion

mechanism locations for a good fit in your table saw's

miter slot. Turning the screw clockwise expands the

mechanism. You'll find (3) of the expansion locations in front of

the fence and (1) underneath the fence. (You'll need to remove

the fence for access.) Adjust these (4) front expansion points

first, expanding a little at each of the locations until the bar slides

smoothly, Fig. 4.

This one-time calibration prepares your INCRA Miter3000 for

work in either miter slot. Just remember that the accuracy of the

INCRA Miter3000 at any subsequent setting is dependent upon

the accuracy of your initial 90° calibration. Verify this important

calibration with a test cut and fine tune as necessary.

1

2

FIG. 4

Remove the large clamping knob and disengage the rear actuator

tooth from the

1

⁄

2

° adjustment plate. Pivot the protractor head to

gain access to (3) of the rear expansion points. To gain access to

the final rear expansion point, remove the rear actuator

thumbscrew and pivot the actuator, Fig. 5. After adjustment,

replace the rear actuator thumbscrew, re-engage the rear actuator

tooth to the 0° notch on the

1

⁄

2

° adjustment plate, then replace

the large clamping knob, washer and fence.

FIG. 5

3

FIG. 8

Calibration

FIG. 6

FIG. 9

FIG. 7

Fence removed for

access

Adjust (4) front

expansion points

Remove large

clamping knob

and washer

Rear

actuator

Protractor head

pivoted for access

Adjust (4) rear

expansion points

Nylon washer

(fits under rear actuator)

Rear

actuator

thumbscrew

1/2°

adjustment

plate

Rear actuator

Left hand

tooth

Front

actuator

tooth

Pivot rear actuator

to make sure

right-hand

tooth

engages

smoothly

into “CAL”

notch

Loosen (3)

socket head

screws to adjust,

if necessary

Engage left-hand

tooth of rear actuator

with “CAL” notch

Square

fence to

blade

Loosen (3) socket

head screws