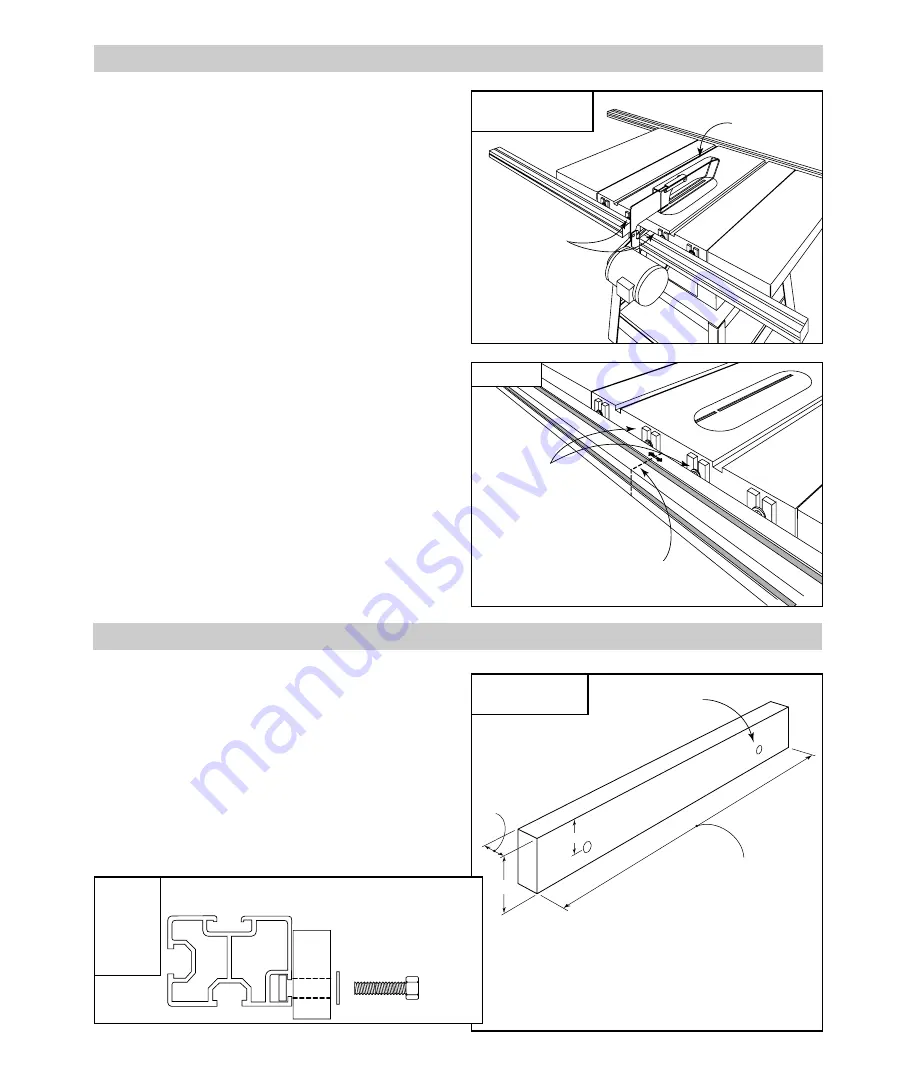

If you wish to add a

3

⁄

4

" thick table board between the right

hand extension wing of your table saw and the TS III base

mount assembly, begin by making two of the wooden

supports like the one shown in

. For the length of

the support, measure the distance between your extension

wing and the base mount assembly. Loosely attach the

fasteners through the holes in the supports. Remove the

base assembly from your saw, then slide the square nuts

into the inside T-slots on each rail,

. Cut a table

board to fit and screw to the supports. The oversize holes

in the support should allow range for positioning the table

board flush with your table saw top.

If, after reinstalling the blade guard and tilting the motor, you

find that the rear rail interferes with the blade guard, you

must add the two remaining rail mounting brackets and split

the rear rail to provide the necessary clearance as shown in

. Begin by removing the base mount assembly.

Loosen the bolts that secure the rear rail to the existing

brackets and slide the rail off. Reinstall the blade guard,

then locate the positions for the additional rail mounting

brackets on either side of the blade guard. The mounting

brackets should be placed as close as possible to the blade

guard, but before drilling the mounting holes, make sure to

check the positions for clearance when the blade is tilted to

45°. When you have found the mounting bracket locations,

drill a

3

⁄

8

"diameter hole in the center of each position. The

center of the hole should be about 1

1

⁄

8

" below the table top.

Remove blade guard, then using

3

⁄

8

–16 x 1

1

⁄

2

" hex bolts,

nuts and washers, attach the extra mounting brackets

loosely in place. Install the rail bolts as shown in

on

page 4, then slide the rear rail back into position. Tighten

all rail mounting bolts, then tighten the two bolts that secure

the brackets to your table saw. Use a hacksaw to make a

cut through the rear rail about halfway between the two

additional rail mounting brackets. Loosen the bolts that

secure the rails to the brackets and slide the rails to create

an opening large enough to reinstall the blade guard. See

. Again, tilt the blade to 45° to check for clearance.

Once the rail positions are established, sand or file the cut

ends of the rails to remove any sharp edges. Tighten the

bolts that secure the rails, then repeat the alignment and

calibrations starting with

on page 7.

BLADE GUARD ADJUSTMENTS

FIG. 26

Rear rail modification

Two rail mounting

brackets are used

on each side of

blade guard to

provide support for

split rear rail

modification

Blade guard

FIG. 27

Cut through rear rail

between additional mounting

brackets and separate the two rail

sections to create opening for blade guard

EXTENSION TABLE

FIG. 28

Table board support

Note: Above dimensions are

for a

3

⁄

4

" thick table board.

Adjust hole position for

different table board thickness

DETAIL

28A

Attaching

table

board

support

1

5

⁄

32

"

3

⁄

4

"

3

⁄

8

" dia. hole

For length, measure

distance between

extension wing and

base assembly

Fasteners required:

(4)

1

⁄

4

– 20 x 1" hex bolts

(4)

1

⁄

4

" flat washers

(4)

1

⁄

4

– 20 square nuts

1

3

⁄

4

"

INCRA TS III Owner’s Manual

11

Additional rail

mounting brackets