14

EN

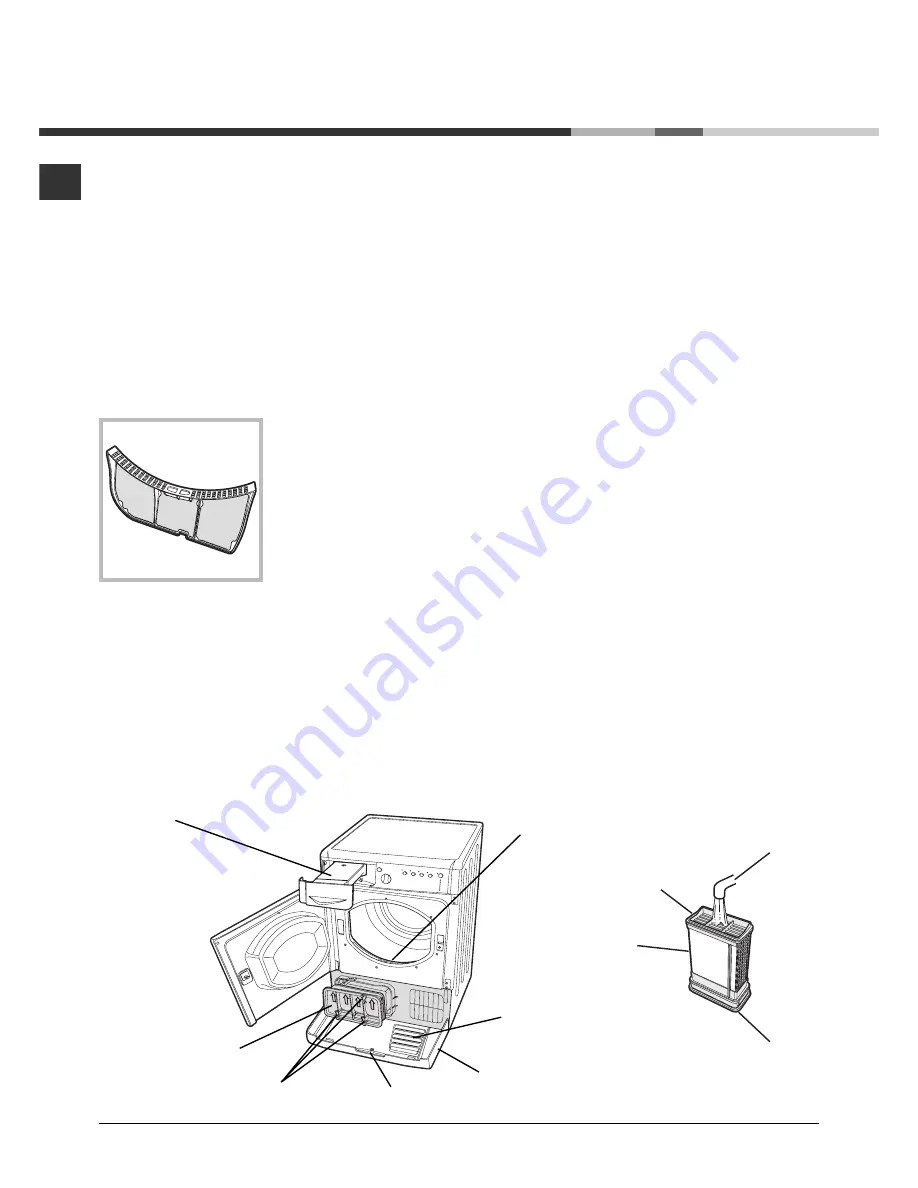

Water

container

Condenser unit

Condenser cover

Catches

Filter

Handle

Air intake

Tap

Rear

Front

Condenser unit

Care and maintenance

Disconnecting the power supply

Disconnect the dryer when not in use or during cleaning

and maintenance operations.

Cleaning the filter after each cycle

The filter is a fundamental component of the dryer: its

function is to collect lint and fluff that form during drying.

Clean the filter once drying is completed, by rinsing it under

running water or cleaning it with a vacuum cleaner. Should the

filter become clogged, the flow of air inside the dryer will be

seriously hampered: drying times becomes longer and more

energy is consumed. Moreover, the dryer may become

damaged.

The filter is located in front of the dryer seal

(see Picture).

Removing the filter:

1. Pull the filters plastic

handle upwards

(see

Picture).

2. Clean the fluff off the filter

and replace it correctly.

Ensure that the filter is

pushed fully home.

Do not use the dryer

unless the filter has been

replaced in its holder.

Checking the drum after each cycle

Rotate the drum manually to remove smaller items

(handkerchiefs) that could have been left inside the dryer.

Cleaning the drum

Avoid using abrasives, steel wool or stainless steel

cleaning agents to clean the drum.

A coloured film may appear on the stainless steel drum

surface: it may be caused by a combination of water and/or

cleaning agents such as wash-softeners. This coloured film

does not affect the dryers performance.

Emptying the water container after

each cycle

Remove the water container and empty it into a sink or

other suitable drain outlet, then replace it correctly.

Always check the water container and empty it before

starting a new drying cycle.

Cleaning the condenser unit

Remove the condenser

(see Picture below)

unit regularly

(monthly) and clean off any fluff deposits from the plates

by rinsing it with cold water running on the rear end of the

condenser.

Removing the condenser:

1. Disconnect the dryer from the power supply and open the

door.

2. Open the condenser cover

(see Picture below)

, unlock the

three catches by turning them 90° anti-clockwise, then

pull on the grip to remove the condenser.

3. Clean the surface of the seals and replace the unit with the

arrows pointing upwards, while making sure that the

catches are securely fixed.

Cleaning the tumble dryer

The external metal, plastic and rubber parts can be

cleaned with a damp cloth.

Clean the front air intake grille regularly (every 6 months)

with a vacuum cleaner to remove any lint, fluff or dust

deposits. Furthermore, remove any lint deposits from the

front part of the condenser and from the filter area, using a

vacuum cleaner every so often.

Do not use solvents or abrasives.

Have the dryer checked regularly by authorised technical

personnel in order to ensure that the electrical and

mechanical parts work safely

(see Assistance)

.

Summary of Contents for IDCA 8350 B

Page 19: ...EN 19 ...

Page 20: ...20 EN 195089408 00 11 2010 ...