2

GB

Installation

!

This instruction manual should be kept in a safe place for

future reference. If the washer-dryer is sold, transferred or

moved, make sure that the instruction manual remains with

the machine so that the new owner is able to familiarise

himself/herself with its operation and features.

!

Read these instructions carefully: they contain vital infor-

mation relating to the safe installation and operation of the

appliance.

Unpacking and levelling

Unpacking

1. Remove the washer-dryer from its packaging.

2. Make sure that the washer-dryer has not been damaged

during the transportation process. If it has been damaged,

contact the retailer and do not proceed any further with the

installation process.

3. Remove the

4

protective

screws (used during tran-

sportation) and the rubber

washer with the correspon-

ding spacer, located on the

rear part of the appliance

(

see figure

).

4. Close off the holes using the plastic plugs provided.

5. Keep all the parts in a safe place: you will need them

again if the washer-dryer needs to be moved to another

location.

!

Packaging materials should not be used as toys for

children.

Levelling

1. Install the washer-dryer on a flat sturdy floor, without re-

sting it up against walls, furniture cabinets or anything else.

2. If the floor is not perfectly

level, compensate for any

unevenness by tightening

or loosening the adjusta-

ble front feet (

see figure

);

the angle of inclination,

measured in relation to the

worktop, must not exceed

2°.

Levelling the machine correctly will provide it with stability,

help to avoid vibrations and excessive noise and prevent it

from shifting while it is operating. If it is placed on carpet or

a rug, adjust the feet in such a way as to allow a sufficient

ventilation space underneath the washer-dryer.

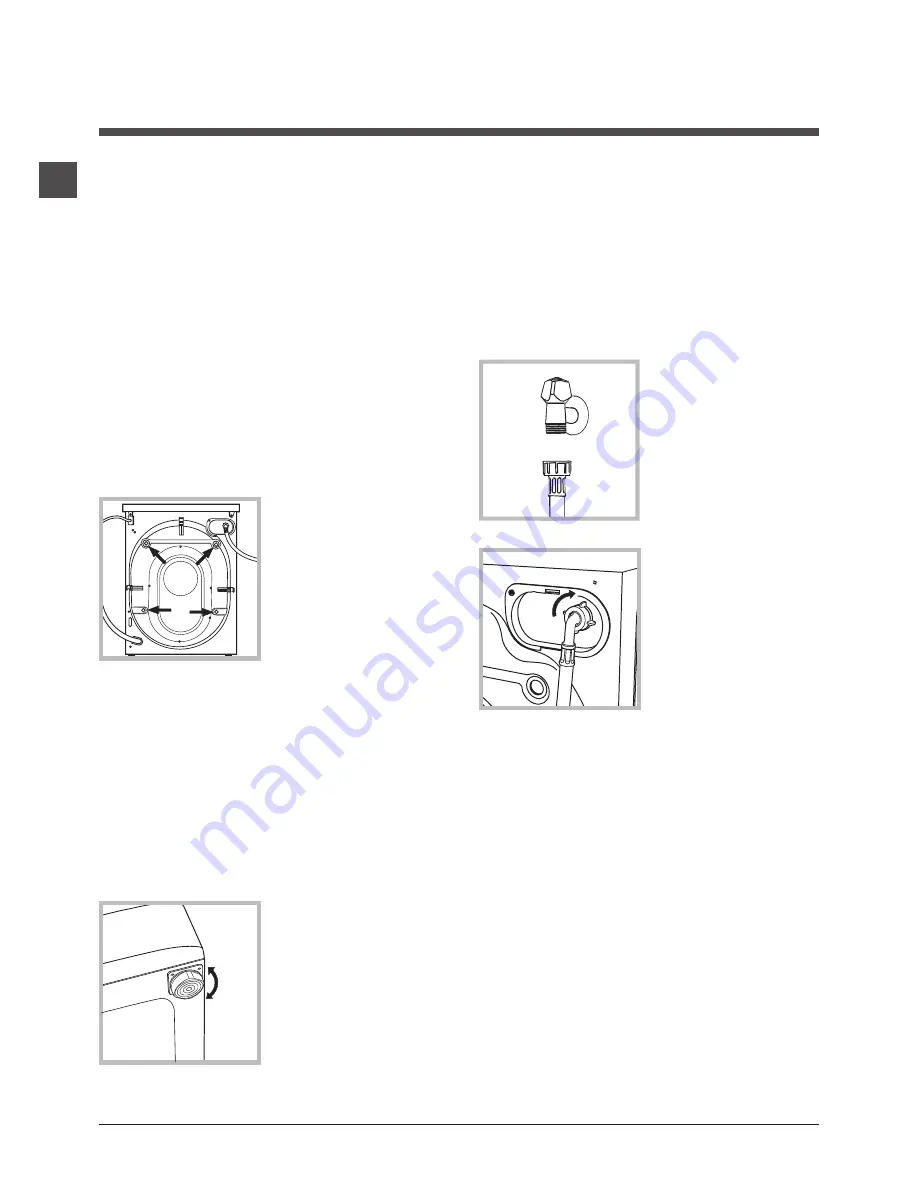

Connecting the electricity and water

supplies

Connecting the water inlet hose

1. Connect the supply pipe

by screwing it to a cold

water tap using a ¾ gas

threaded connection

(see

figure).

Before performing the con-

nection, allow the water to

run freely until it is perfectly

clear.

2. Connect the inlet hose

to the washer-dryer by

screwing it onto the corre-

sponding water inlet of the

appliance, which is situa-

ted on the top right-hand

side of the rear part of the

appliance

(see figure)

.

3. Make sure that the hose is not folded over or bent.

!

The water pressure at the tap must fall within the values

indicated in the Technical details table

(see page 5).

!

If the inlet hose is not long enough, contact a specialised

shop or an authorised technician.

!

Never use second-hand hoses.

!

Use the ones supplied with the machine.