A

SS

I

ST

ANCE

G

B

52

Service Manual

Ne

w

E

lectronic Cold Platform 2005

Edition

2005.03.25

Language

E

nglish

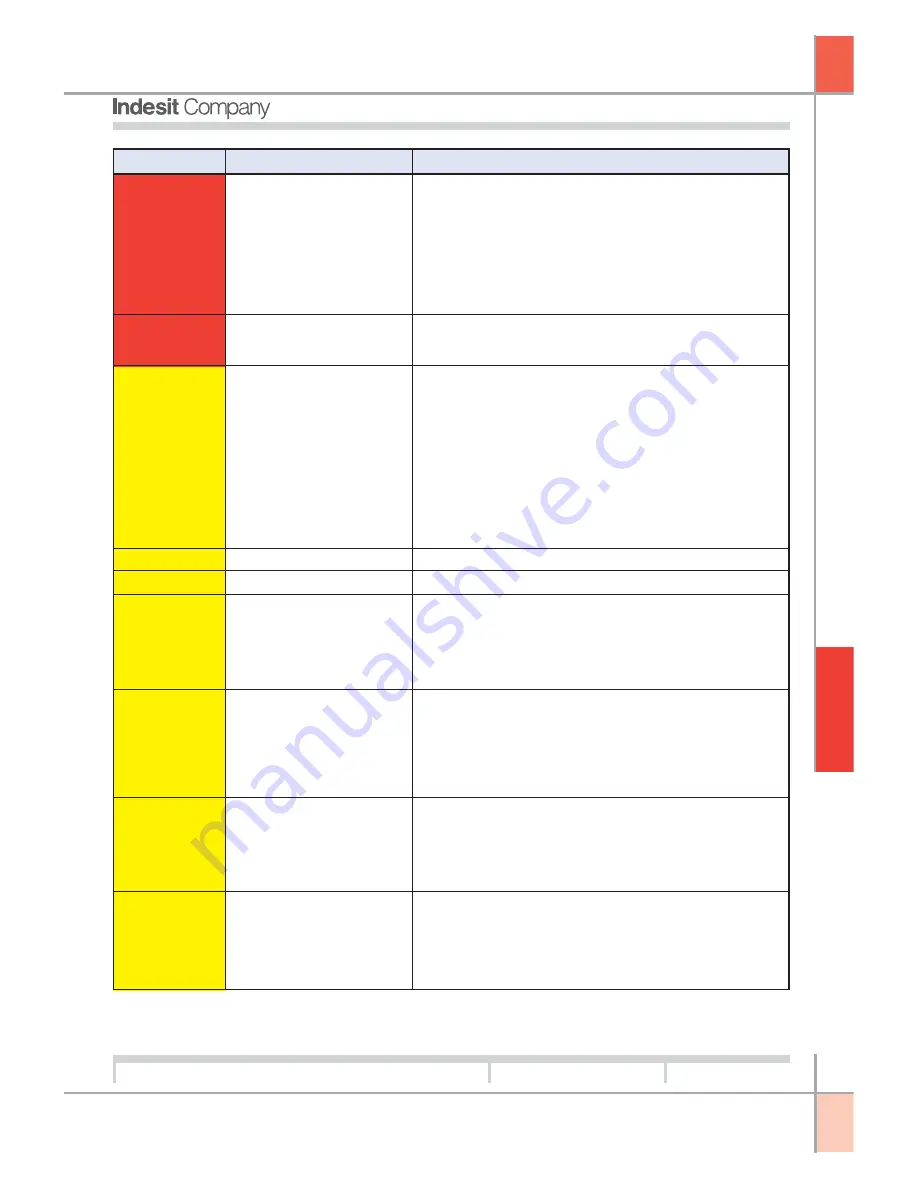

FAULT

CORR

E

CTIV

E

ACTIONS

CAUS

E

-

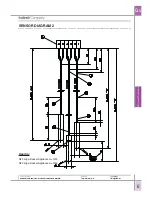

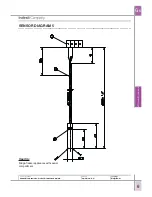

Check efficiency of contacts on PCB connector J8;

-

Check for impedance on wiring connector J8 pins 2 and 1 and ensure that

the value is compatible with the value given in the relevant table;

-

Check correct switching of the solenoid valve. Check, with the compressor

running, that the solenoid valve switches when the refrigerator compart-

ment is set to OFF by means of the temperature control knob

-

Renew solenoid valve;

-

Renew PCB.

-

I

n the case of an original production PCB, renew PCB and EEPROM;

-

I

n the case of replacement PCB and EEPROM, check correct insertion of

EEPROM in PCB socket.

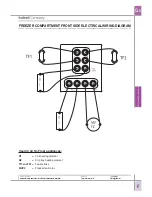

For L

E

D interface PCB:

-

Check efficiency of contacts on PCB connector J13;

-

Check continuity of connector J13 / 5-way and 7-way connectors of LED

PCB;

-

Renew main PCB;

-

Renew display PCB;

For Digit interface PCB:

-

Check efficiency of contacts on PCB connector J13;

-

Check continuity of connector J13 / 4-way interface PCB connector;

-

Renew main PCB;

-

Renew display PCB.

-

Renew PCB.

-

Renew PCB.

-

Check efficiency of contacts of PCB connector J11;

-

Check NTC sensor, ensuring that the impedance value read on pins 3 and

4 of wiring connector J11 is compatible with the values in the temperature-

impedance correlation table (also heat the sensor by holding it with your

hand where possible and checking the change in the impedance value);

-

Renew PCB.

-

Check efficiency of contacts of PCB connector J11;

-

Check NTC sensor, ensuring that the impedance value read on pins 1 and

2 of wiring connector J11 is compatible with the values in the temperature-

impedance correlation table (also heat the sensor by holding it with your

hand where possible and checking the change in the impedance value)

-

Renew PCB.

-

Renew appliance

-

Check efficiency of contacts of PCB connector J11;

-

Check NTC sensor, ensuring that the impedance value read on pins 5 and

6 of wiring connector J11 is compatible with the values in the temperature-

impedance correlation table (also heat the sensor by holding it with your

hand where possible and checking the change in the impedance value);

-

Renew PCB.

-

Check efficiency of contacts of PCB connector J11;

-

Check NTC sensor, ensuring that the impedance value read on pins 1 and

2 of wiring connector J11 is compatible with the values in the temperature-

impedance correlation table (also heat the sensor by holding it with your

hand where possible and checking the change in the impedance value)

-

Renew PCB.

F08

I

ncorrect switching of sole-

noid valve

File setup error (EEPROM

not programmed or faulty).

No communication be-

tween display PCB and

control PCB

F12

F09

F23

FREEZER Air NTC sensor

open / short circuit

F24

F22

F14

FR

I

DGE Evaporator NTC sensor open / short circuit

FR

I

DGE Air NTC sensor

open / short circuit

Ambient NTC sensor U

I

F21

Faulty power PCB

F25

FREEZER Evaporator NTC

sensor open / short circuit

Summary of Contents for New electronic cold platform 2005

Page 73: ......