Orientation

Due to different requirements and/or specifications of the respective

manufacturers, be sure to review the respective manufacturer's

documentation!

To ensure a smooth production process, the chip conveyor should be cleaned and

serviced regularly.

With regular cleaning, any defects can be detected and corrected early. Thus,

prolonged downtime due to repair work can be reduced to a minimum.

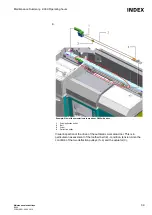

The chip conveyor is used for removal of swarf from the work area and is also a

reservoir for the cooling lubricant. The cooling lubricant is filtered in the chip

conveyor. For this purpose, various filters and filter plates are built into the chip

conveyor. These filters must be cleaned regularly. In particular, make sure that the

area around the cooling lubricant pump(s) is always free of chips or dirt.

For all work in connection with operating materials, the information in

the data sheets of the respective manufacturers and the information

in the document Notes on Operating Materials must be observed.

Requirement

Be sure to interrupt the motion of the conveyor belt by opening

the work area door or switching off the chip conveyor before

commencing cleaning work around the discharge chute!

The conveyor belt can only move when the chip conveyor is switched

on and the work area door is closed.

Procedure

1.

Service and maintenance are to be carried out according to the

manufacturer’s specifications.

Clean the chip conveyor.

2. Clean the discharge chute. Pay particular attention to chip build-up and

remove them around the discharge chute. Chip build-up can accumulate in

the area of the drive roller so that it can become compacted, causing damage

to the conveyor belt including the drive shaft.

3. Check the wipers at the discharge chute and the inlet port.

4. Visual inspection of brush-off device (option).

Maintenance Summary - Care activities

27

Maintenance Instructions

B500

DIE219EN - 05.06.2019