- Check hydraulic system

Orientation

To ensure trouble-free operation, periodic checks of the oil level are necessary. The

fill level must be between the upper and lower marks on the oil sight glass.

Only use hydraulic fluid grade 15/13/10 in accordance with ISO 4406.

Viscosity other than 32 according to DIN ISO 3448 is not admissible.

For all work in connection with operating materials, the information in

the data sheets of the respective manufacturers and the information

in the document Notes on Operating Materials must be observed.

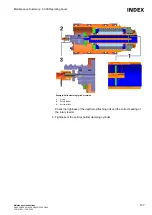

Example: Hydraulic unit G420

a

Filler neck (hydraulic fluid)

b

Fill level indicator

c

Accumulator drain valve

d

Monitoring (level and temperature)

e

Oil drain plug

f

Electrical monitoring (contamination indicator)

g

Pressure gauge (system pressure)

h

Pressure accumulator

i

Safety valve

j

Electrical monitoring (system pressure)

k

Drain hose for hydraulic unit

X

Hydraulic fluid filter (line filter)

Y

Filter bell

Screws on the hydraulic system, the connected components, and the

supply lines must be tightened to the manufacturer's specified

torques.

Maintenance Summary - 4.000 Operating hours

110

Maintenance Instructions

G300.2 G320.2 G400.2 G420 G500.2 G520

DIE147EN - 17.08.2022