Requirement

Specification and quantity of hydraulic fluid or lubricating oil and

grease in accordance with information in the technical data.

The spare parts and utilities as well as operating fluids required for repair or

maintenance should already be available in sufficient quantities.

This is especially true for necessary special tools, without which the maintenance or

repair would not be possible.

Procedure

1. Check the adjustment in the “Released” position – lock with a clamped tool.

2.

A measuring device required to measure the clamping force can

be sourced through INDEX , a representative or the tool

manufacturer.

Check the retraction force. If the retraction force is less than 70% of the

nominal value, take the following measures in the order given : Regrease

and recheck retraction force – replace collet and recheck – completely replace

tool clamp.

3.

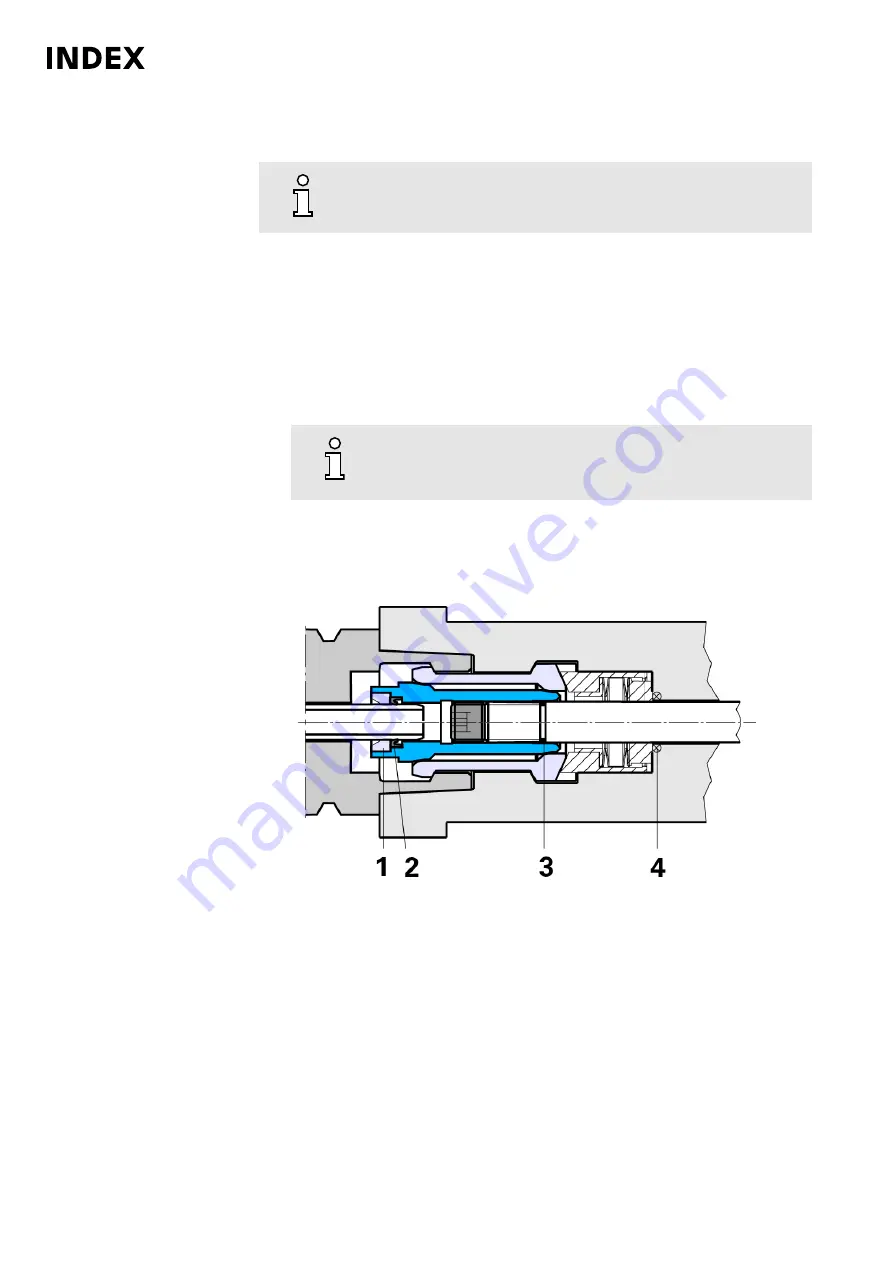

Example: HSK clamping set

1

Brass ring

2

Grooved ring

3

O-ring

4

O-ring

Check grooved ring (2) in clamping taper

4. Remove and check clamping set. Remove clamping set, clean it according to

manufacturer’s instructions, check it for wear (replace if necessary), and

lubricate it. After lubricating, re-check the retraction force. If the retraction force

is still less than 70% of the nominal value, the collet or the complete tool

clamping system must be replaced.

Maintenance Summary - 2.000 Operating hours

60

Maintenance Instructions

G300.2 G320.2 G400.2 G420 G500.2 G520

DIE147EN - 17.08.2022