- Check hydraulic system

Carrying out the maintenance activities described below requires

special knowledge. For this reason, these maintenance activities

must be carried out only by authorized personnel of the

manufacturer!

Orientation

To check the settings of the various components, they can be made

visible in the control system in the Sensor System area. Refer to the

section on the sensor system in the documentation Machine

Operation.

Operating fluids such as hydraulic fluids, cooling lubricants, lubricating greases/oils

are also subject to degradation or aging, and must therefore serviced, refilled or

replaced at regular intervals. The hydraulic fluid must be changed periodically to

ensure reliable operation of the machine. Review of the maintenance and service

logs.

Requirement

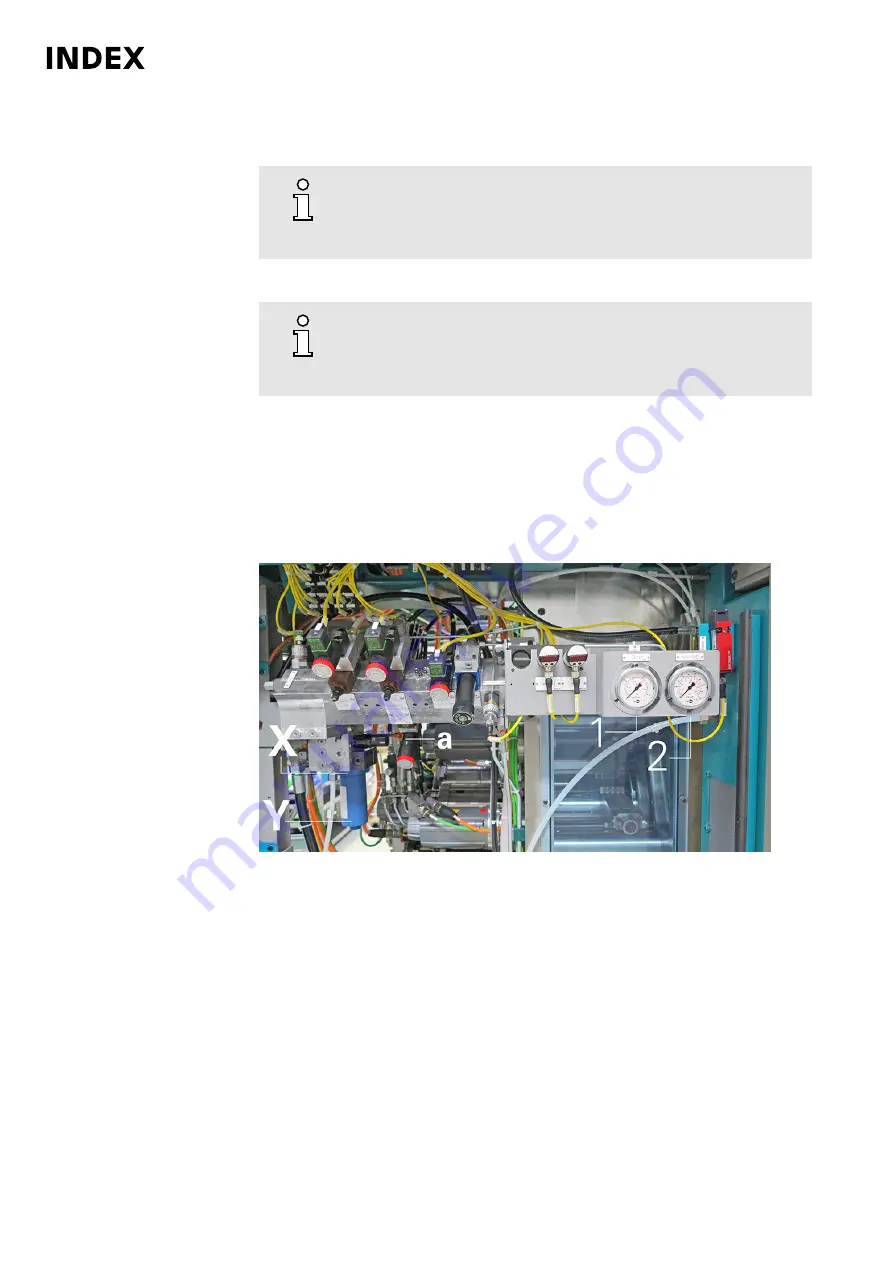

Example: Hydraulic unit MS32-6.2 MS40-6

a

Accumulator drain valve

1

Pressure gauge for system pressure

2

Hydrostatic pressure gauge

X

Hydraulic fluid filter

Y

Filter bowl

The maintenance of the hydraulic system requires the following auxiliary or working

equipment:

- servicing, testing and maintenance schedules/logs of the customer.

- Use an ample supply of cleaning rags – no cotton waste.

- A sufficient amount of hydraulic fluid for refilling/changing. - Hydraulic fluid,

specification and quantity as specified in the technical data.

- Hydraulic fluid filter, main and bypass filter. - Use only original filters.

- Various sizes of jaw and box wrenches, and Allen keys.

Maintenance Summary - 2.000 Operating hours

50

Maintenance Instructions

MS32-6.2

DIM012EN - 03.06.2020

Summary of Contents for MS16-6

Page 10: ...Preface 6 Maintenance Instructions MS32 6 2 DIM012EN 03 06 2020 ...

Page 50: ...Maintenance Summary Care activities 46 Maintenance Instructions MS32 6 2 DIM012EN 03 06 2020 ...

Page 76: ...Maintenance Summary 5 Years 72 Maintenance Instructions MS32 6 2 DIM012EN 03 06 2020 ...

Page 81: ......