- Check main and counter spindles

Carrying out the maintenance activities described below requires

special knowledge. For this reason, these maintenance activities

must only be carried out by staff that has received adequate training

by the machine manufacturer!

Orientation

Checking the main and counter spindles also includes other, additional activities.

Thy should be carried out now, because various different plates and/or covers must

be removed to facilitate access to other components, thus allowing other activities.

- Clean labyrinth rings and space behind the rings.

- Clean the encoder wheels.

- Visual inspection of the hydraulic accessory units. Check aligning and indexing

units, clamping cylinder for leaks.

- Check cooling lubricant and stopper unit with cooling lubricant rotary

distributor.

- Check aligning and indexing units.

- Check O-rings on the clamping devices, replace if necessary

Procedure

1. Remove machine enclosure in the area ofthe spindles

2.

Caution

Sharp edges on cover.

Cuts.

Wear personal protective equipment.

Remove cover over the spindles on the clamping cylinder

3.

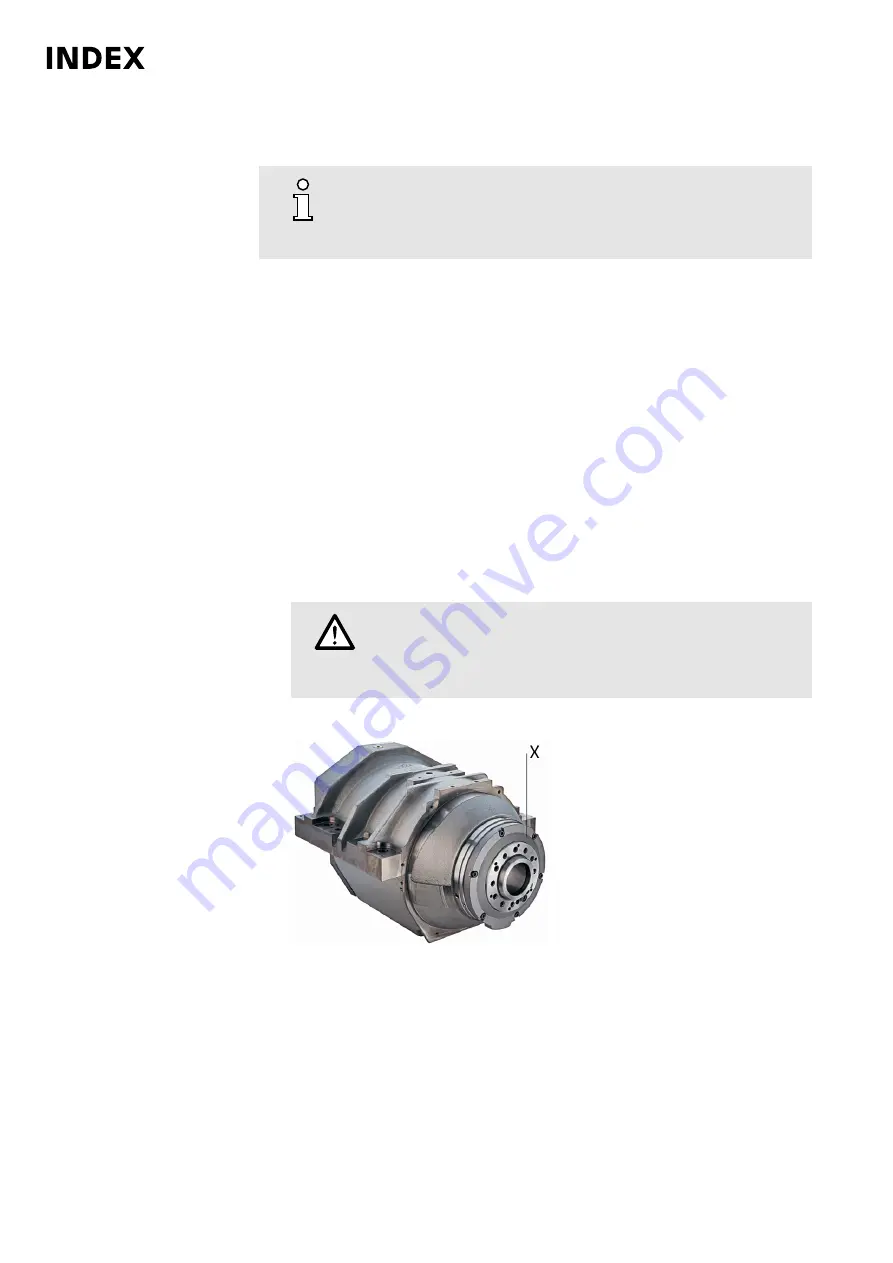

Example: Labyrinth ring (X) on the main spindle, G-machine

Clean the space behind the labyrinth rings (X) with rags.

Maintenance Summary - 4.000 Operating hours

86

Maintenance Instructions

R200

LR1702.10181 - 05.06.2019