4.

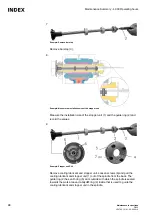

Example: Encoder wheel Heidenhain ERM

Clean encoder wheels. Do not use any metal tools or objects for cleaning.

To ensure optimum data exchange between the encoder and the encoder

wheel, the encoder wheel must be cleaned regularly. Ensure absolute

cleanliness, so that the cleaning does not lead to additional contamination of

the encoder wheel or the encoder.

5. Check the tightness of the hydraulic accessory units. Check the aligning and

indexing units, solid or open-center cylinders for leaks.

6.

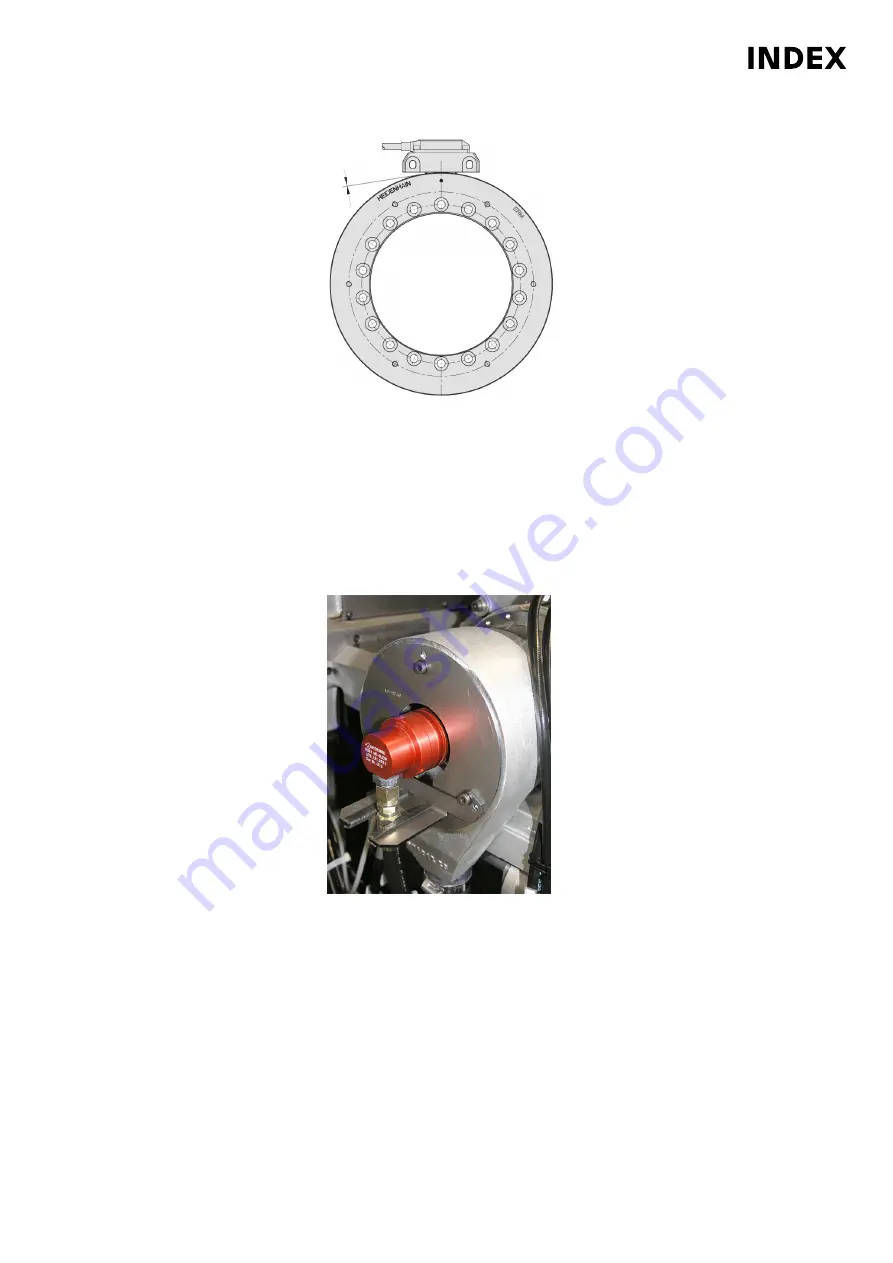

Example: Cooling lubricant rotary distributor (e.g., from Hydronic)

Check cooling lubricant distributor rotary distributor. Detach the cooling

lubricant rotary distributor and check that cooling lubricant flows out. Cooling

lubricant should escape from the rotary distributor when the machine and

cooling lubricant pump are switched on and the work area door is closed.

Maintenance Summary - 4.000 Operating hours

87

Maintenance Instructions

R200

LR1702.10181 - 05.06.2019