- Check outer wipers of roller guides

Carrying out the maintenance activities described below requires

special knowledge. For this reason, these maintenance activities

must only be carried out by staff that has received adequate training

by the machine manufacturer!

Orientation

Regularly checking wipers of the roller guides prevents accelerated wear of the

linear guides. This test is a visual inspection. But if the wiper is destroyed and no

longer snugly contacts the contour of the guide, it must be replaced. It is essential

to ensure absolute cleanliness when removing and installing the wiper.

Requirement

Move the tool carriers to a suitable position. For checking the outer wipers, parts of

the machine enclosure must be removed from the machine. In most cases, access

to the wipers is best in the end positions of the respective axes. To move to the

positions in which the wipers can be checked, it may be necessary to switch the

machine on/off several times.

Procedure

1. Move the tool carrier to the position required for checking.

2.

Caution

Moving tool carriers, spindles, or belt drives.

Risk of bruising and lacerations.

Switch off the machine via the main switch or shut down with the

emergency stop.

Remove relevant machine enclosure.

3.

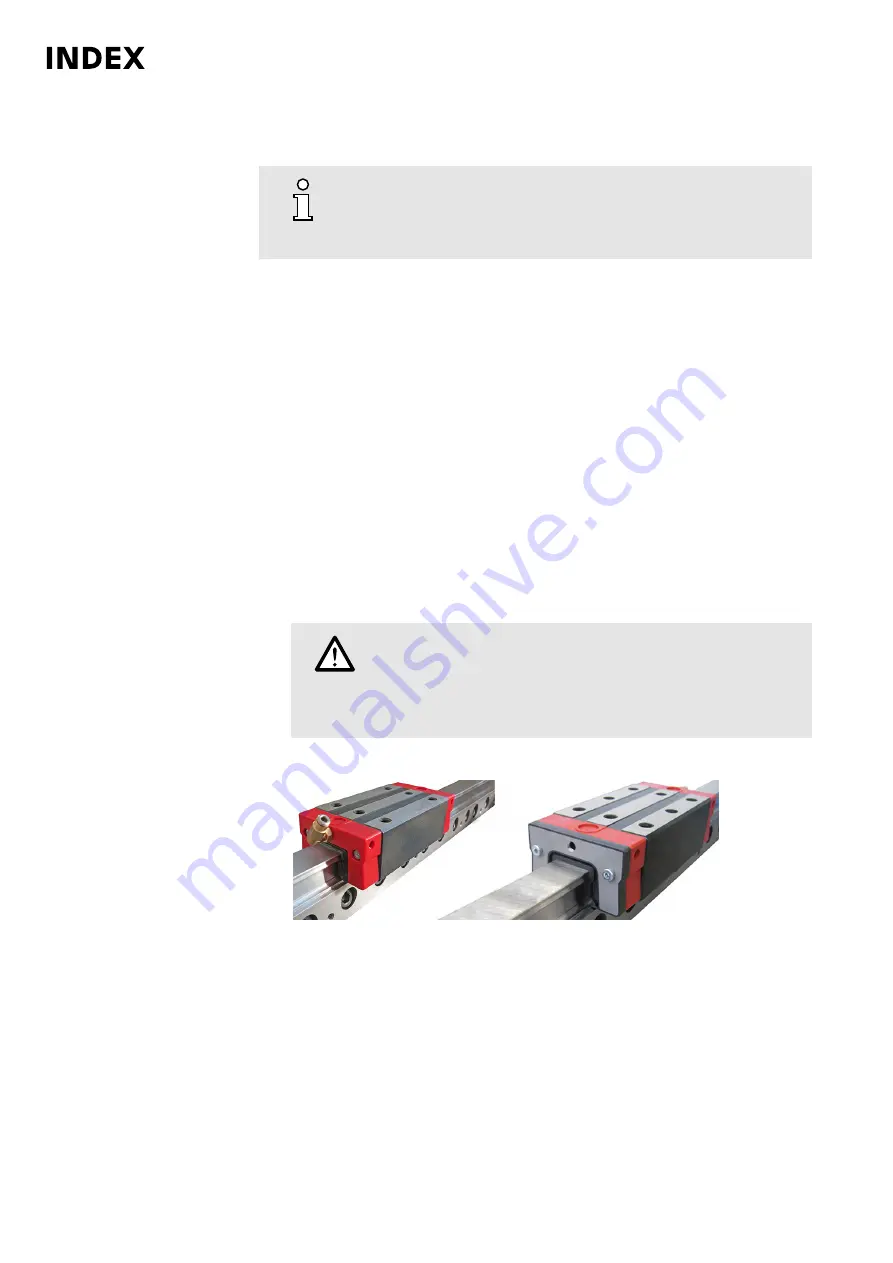

Example: Wiper on the trolley of the roller guide (view from the preassembly).

Check wipers.

4. Replace wipers. Loosen and remove the mounting screws of the wiper on the

trolley. Push the wiper from the guide bar. Clean the guide bar and push a new

wiper onto the guide bar. Finally lightly oil the guideway.

Maintenance Summary - 2.000 Operating hours

58

Maintenance Instructions

R200

LR1702.10181 - 05.06.2019